9001:2005

CERTIFICATED

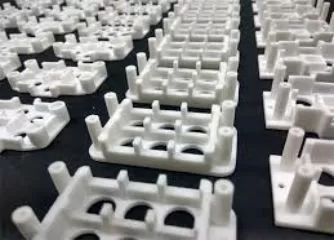

VACUUM CASTING

MACHINES 50+

VACUUM CASTING

PARTS 250000+

PLASTIC

MATERIALS 100+

Vacuum casting is one of GD-HUB's key processing services that we use to manufacture plastic parts with intricate details and complex geometries for our customers. This process is ideal for producing high quality parts in small to medium batches with good surface finish and dimensional accuracy. The materials used in vacuum investment casting can vary depending on the customer's specific application requirements, from silicone and polyurethane to thermoplastics. Vacuum casting service is widely used to produce plastic parts for many industries, including but not limited to consumer electronics, medical and automotive.

Why Choose GD-HUB’s Vacuum Casting

If you are looking for high quality vacuum casting services for your rapid prototyping project, GD-HUB will exceed your expectations. Our team of experts is dedicated to providing customized solutions to meet the individual needs of your project. We provide 24/7 engineering support and work with you to design and develop precise vacuum casting molds to produce the most desirable vacuum casting parts.GD-HUB with over 13 years of experience in the rapid prototyping industry, you can trust us to deliver the best results for your vacuum casting prototyping project.

ISO certified

ISO certified

Molds are durable for 20 or more copies

Molds are durable for 20 or more copies

Vacuum Casting Parts with Tight Accuracy (±0.05mm)

Vacuum Casting Parts with Tight Accuracy (±0.05mm)

24H/7d Engineering Support

24H/7d Engineering Support

Capabilities Of GD-HUB

GD-HUB offers comprehensive vacuum casting capabilities, providing end-to-end services from mold design to mass production. Our vacuum casting services are ideal for small batch projects that require quick prototyping. We also offer post-treatment services, including surface treatment, to ensure that your prototypes are flawless. With our commitment to quality, competitive pricing, and fast turnaround times, you can trust GD-HUB to deliver accurate and dependable vacuum casting prototyping solutions for all your project needs.

Complex geometries

Vacuum casting prototyping is capable of producing parts with complex geometries and intricate details such as undercuts, textures and thin walls. All the details within the original mold are captured through the use of silicone molds. The vacuum casting process fills the mold completely and uniformly with material, resulting in prototypes with tight tolerances and consistent dimensions.

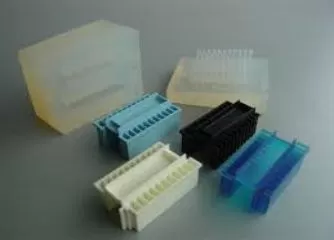

Material versatility

Vacuum casting prototyping can be used with a wide range of materials, including various types of plastics, rubbers, and metals. Color options is flexible, GD-HUB carefully incorporate various color you want pigments to achieve the intended effects on your finished products.

Small & medium volume production

GD-HUB's vacuum casting service is ideal for small to medium volume production. Moreover, our vacuum casting process is relatively fast, with short lead times, which facilitates quick turnaround.

Processable Materials

GD-HUB's Vacuum Casting service offers a variety of processable materials for your prototype project needs. Our compatible plastic materials include polypropylene, ABS, nylon, acrylic, PC, rubber, and soft elastomer with varying degrees of hardness. Additionally, we can add glass fibers to increase the stiffness of ABS and nylon for even more design options. Check out our material list to see if we have a material that meets your unique requirements, or contact us directly to discuss your project needs.

Related Information:

Vacuum Casting vs Injection molding