9001:2005

CERTIFICATED

SURFACE FINISHING

MACHINE 50+

SURFACE FINISHING

PROCESS 20+

MATERIAL

METAL & PLASTIC 100+

Precision surface finishing is a critical final step in the manufacturing process that enhances the appearance, texture and durability of a material or product. This process achieves a desired finish or texture by altering or removing the surface layer of a material. Surface finishing can be applied to a variety of materials including metals, plastics, ceramics, and composites.GD-HUB's surface finishing is a critical process for components in many industries including automotive, aerospace, electronics, and construction. Whether for aesthetic or functional purposes, surface finishing services play a vital role in the overall quality of a product.

Why Choose GD-HUB’s Surface Finishing

GD-HUB has been deeply involved in the manufacturing industry for over 10 years, and surface finishing has become one of our most specialised processes. With state-of-the-art equipment and a knowledgeable team, our surface finishing services make it easy to achieve any surface finish required for your project, giving your parts the ultimate in precision, aesthetics, and functionality. Trust our ability to create the perfect surface finishing solution for you.

ISO certified

ISO certified

Low Volume

Low Volume

Multiple surface finishing for multiple materials

Multiple surface finishing for multiple materials

24H/7d Engineering Support

24H/7d Engineering Support

Capabilities of GD-HUB Surface Finishing

GD-HUB is a best manufacturer for all of your surface finishing choice. Our services cover a wide range of materials and we have the perfect solution no matter what materials are involved in your project. GD-HUB committed to providing top quality and visually stunning finishes, and offering the shortest lead times to ensure your project is completed as quickly as possible to be first to market. Browse our surface preparation techniques to see how we can help you achieve the results you are looking for.

Functional improvements

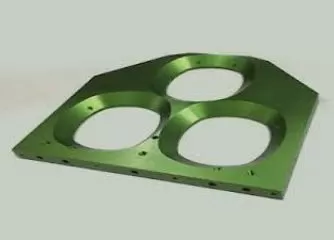

GD-HUB's surface finishing can enhance the functionality of a material by improving its mechanical, electrical, or chemical properties. For example, the process of anodizing aluminum can make parts more resistant to corrosion and wear, while surface hardening can increase the prototype's hardness and toughness.

Aesthetic improvements

GD-HUB's surface finishing can also improve the appearance of your parts, making parts more visually appealing. For instance, electroplating can give a metallic surface a shiny, reflective finish, while powder coating can provide a durable and vibrant color coating to a surface.

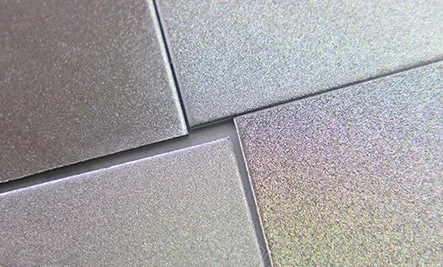

Surface treatment

GD-HUB's surface finishing can also be used to prepare a surface for further processing or application. For example, cleaning and etching can be used to remove contaminants and create a roughened surface that allows better adhesion of a coating or adhesive.

Below are the specifications of the plastic finishing techniques rendered by us.

Processable Materials

Surface finishing techniques can be applied to parts manufactured through various processes, including: Machining, 3D Printing/Additive Manufacturing, Injection Molding, Casting, Stamping and Forming, Extrusion; Each of these manufacturing processes may require specific types of surface finishing techniques based on the material used and the desired properties of the finished part. GD-HUB offers surface finishing services that are suitable for a diverse range of processable materials, such as PMMA, ABS, PC, Aluminum, Copper, Brass, Steel, and Stainless Steel. Our team understands that each prototype project has unique requirements, we are always available to discuss your specific needs for solutions. Please review our processing list to see if they align with your project, or feel free to contact us directly to discuss your options.