9001:2005

CERTIFICATED

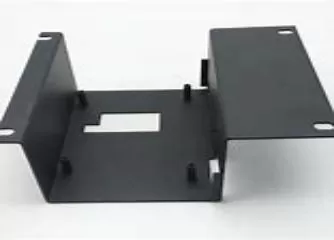

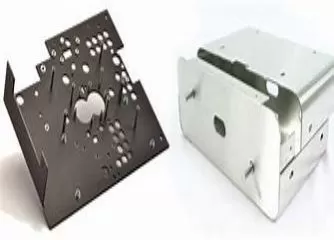

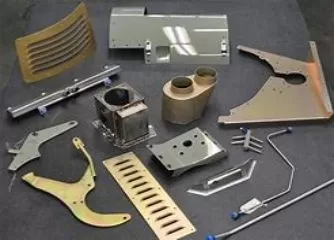

SHEET METAL FABRICATION

MACHINES 20+

SHEET METAL PARTS

MADE MONTHLY 10000+

METAL

MATERIALS 100+

Sheet metal fabrication, also known as sheet metal processing, is a crucial process for creating various products of different shapes and sizes. The process involves using thin sheet metal parts and utilizing techniques such as shearing, bending, buckling, forming, welding, and riveting. These sheet metal services allow for the creation of parts with unchanged thickness throughout the processing. Custom sheet metal fabrication services is an essential part of manufacturing and is used in a wide range of industries, including automotive, aerospace, and construction.

Why Choose GD-HUB’s Sheet Metal Fabrication

GD-HUB is a manufacturer with the ability to meet all your sheet metal fabrication needs and is the best choice for your small volume sheet metal rapid prototyping projects. We offer the most competitive prices without compromising quality, striving for the ultimate in accuracy and efficiency to ensure that you receive the perfect finished product. We focus on every detail to help you bring your ideas to life quickly and efficiently.

ISO certified

ISO certified

Low Volume

Low Volume

Fast delivery and quick turnaround

Fast delivery and quick turnaround

24H/7d Engineering Support

24H/7d Engineering Support

Capabilities Of GD-HUB Sheet Metal Fabrication

If your project involves creating custom metal parts and prototypes with consistent wall thicknesses, sheet metal fabrication is the best solution. GD-HUB has the most comprehensive sheet metal fabrication services, including waterjet cutting, laser cutting, plasma cutting, stamping, bending, welding and surface finishing. With our expertise and attention to detail, you can trust GD-HUB to deliver top-notch results.

Laser cutting

Laser cutting is a precise and efficient cutting method that uses a high-powered laser beam to cut through sheet metal. Compared to other cutting technologies, Laser cutting is more precise, and can be used to cut intricate shapes and patterns quickly. It is suitable for a wide range of metals, including stainless steel, aluminum, and brass.

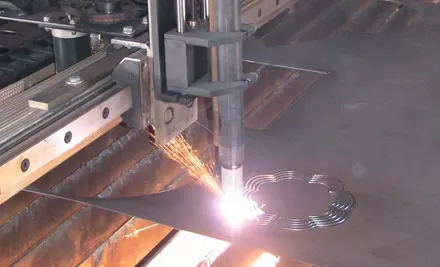

Plasma cutting

Plasma cutting uses a plasma torch to cut through metal. Plasma cutting is ideal for cutting thick metal sheets and can be used to cut through materials that are difficult to cut with other methods, such as rusted or painted metal. Plasma cutting is ideal for thick and tough materials.

Metal bending

Metal bending use of a press brake machine to bend and shape sheet metal. Metal bending is a versatile technique that can be used to create a wide range of shapes and sizes, including angles, channels, and boxes. Metal bending is a versatile technique that can create a wide range of shapes and sizes.

Processable Materials

GD-HUB offers Sheet Metal Fabrication services that can work with a variety of metal materials, such as Aluminum, Copper, Brass, Steel, and Stainless Steel. Our materials list is extensive, but if you have specific requirements for your prototype project, please don't hesitate to contact us. We are always happy to discuss your unique needs and find a solution that works for you.