9001:2005

CERTIFICATED

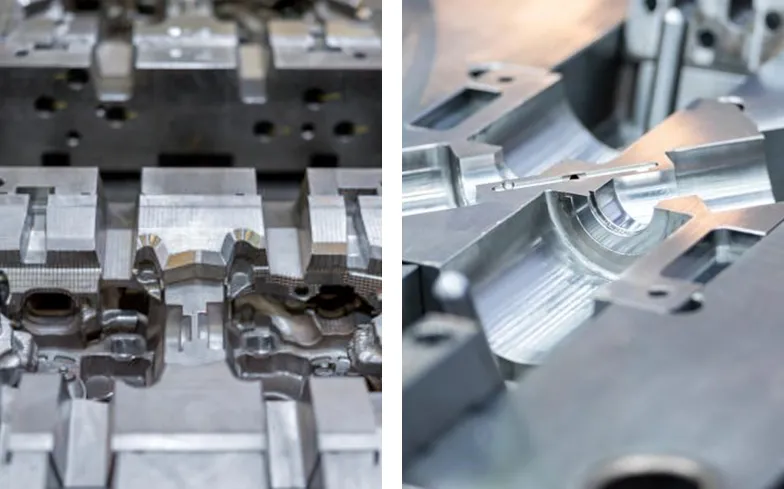

DIE CASTING

MACHINES 30+

DIE CASTING

PARTS 100000+

METAL

MATERIALS 100+

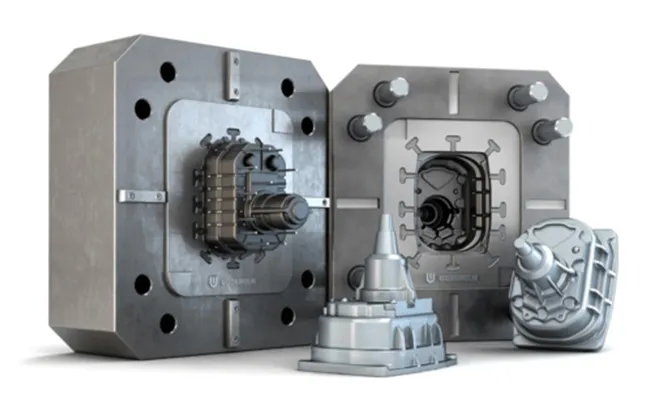

Die casting is a highly efficient manufacturing process in which molten metal is injected into a mould cavity under high pressure. A steel die is machined into the desired part shape and the cavity is formed by two durable steel dies. Due the die casting process allows for the automated, efficient and rapid production of complex parts with smooth surfaces in large quantities, GD-HUB's die casting services serve a wide range of customers in the automotive, aerospace, electronics,and consumer goods industries.

Why Choose GD-HUB’s Die Casting

With years of industry die casting experience and the industry's most advanced die casting equipment, GD-HUB's team has strict quality requirements and is committed to producing the best parts and prototypes for businesses.GD-HUB offers both hot chamber and cold chamber die casting processes and provides personalized customisation services such as custom materials, surface treatments, tolerances and manufacturing processes to meet your unique requirements. Choose GD-HUB for the highest quality die casting services!

ISO certified

ISO certified

Fast delivery and quick turnaround

Fast delivery and quick turnaround

Leading quality inspection and testing

Leading quality inspection and testing

24H/7d Engineering Support

24H/7d Engineering Support

Capabilities Of GD-HUB Die Casting

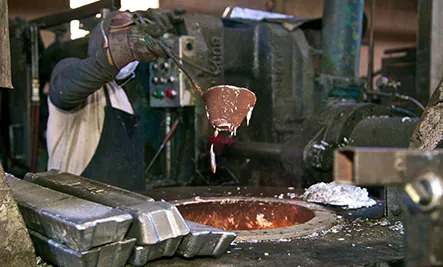

GD-HUB offers two types of die casting processes: hot chamber die casting and cold chamber die casting. With more than ten years of experience in the die casting service industry, we are equipped with the most advanced equipment, which, together with other processing capabilities, aim to focus on all your requirements and ensure the highest quality, precision Competitive pricing with the shortest lead time to help you turn around quickly is our commitment.

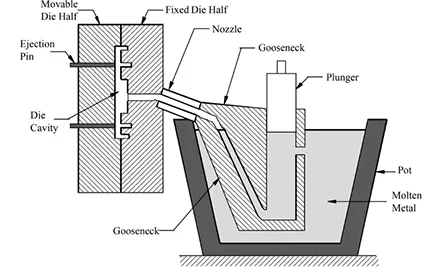

Hot chamber die casting

Hot chamber die casting is a process used to manufacture small to medium sized zinc, tin and lead metal parts. Hot chamber die casting is typically used for high-volume production of small, complex parts such as gears, connectors, and electronic components. Hot chamber die casting uses metals with low melting points and the hot chamber process is typically faster than the cold chamber process, making it ideal for high volume production of small parts.

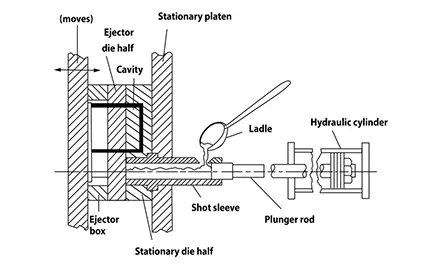

Cold chamber die casting

Cold chamber die casting is a process used to make large parts in alloys such as aluminum, magnesium and copper. Cold chamber die casting is typically used for parts that require high strength and durability, such as automotive parts, engine parts and aerospace components.

Cold chamber die casting uses metals with higher melting points, and the cold chamber process produces parts with higher strength and durability, making it more suitable for making larger parts for more demanding applications.

Die casting

Die casting can produce metal parts with high precision and accuracy, and parts produced through die casting are often strong and durable, making them suitable for a variety of applications.

Custom die casting can be a cost-effective way to meet the demands of high-volume production runs.

Processable Materials

GD-HUB offers die casting services for a variety of processable materials, such as aluminum, zinc, magnesium, lead, copper, and various alloys including Aluminum Alloys, Zinc Alloys, and Magnesium Alloys. Our materials list is extensive, but if you have specific requirements for your prototype project, please don't hesitate to contact us directly to discuss your needs. We are committed to finding the right material to meet your unique specifications.