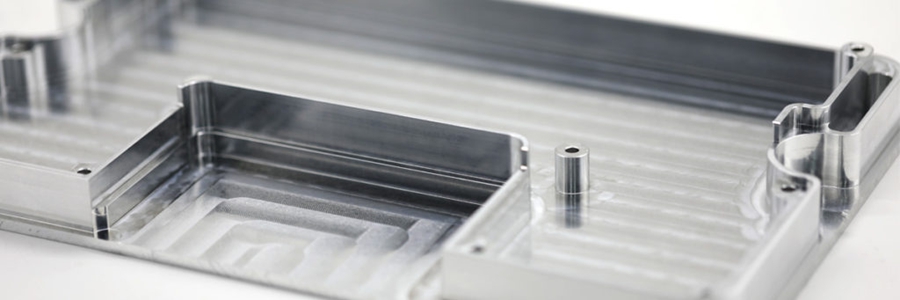

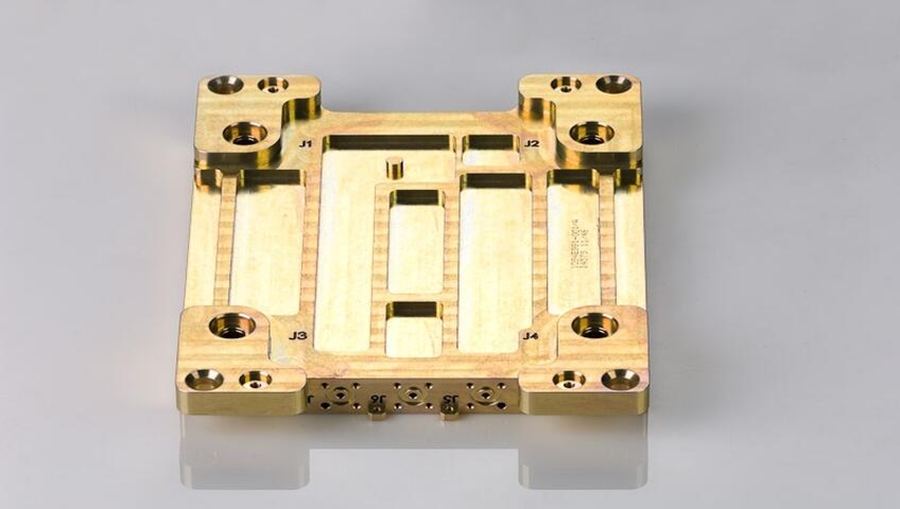

As-machined

The standard finish for our parts, the "as machined" finish, has a surface roughness of 3.2 μm (126 μin), which removes sharp edges and deburs parts cleanly.

Applicable materials: All materials

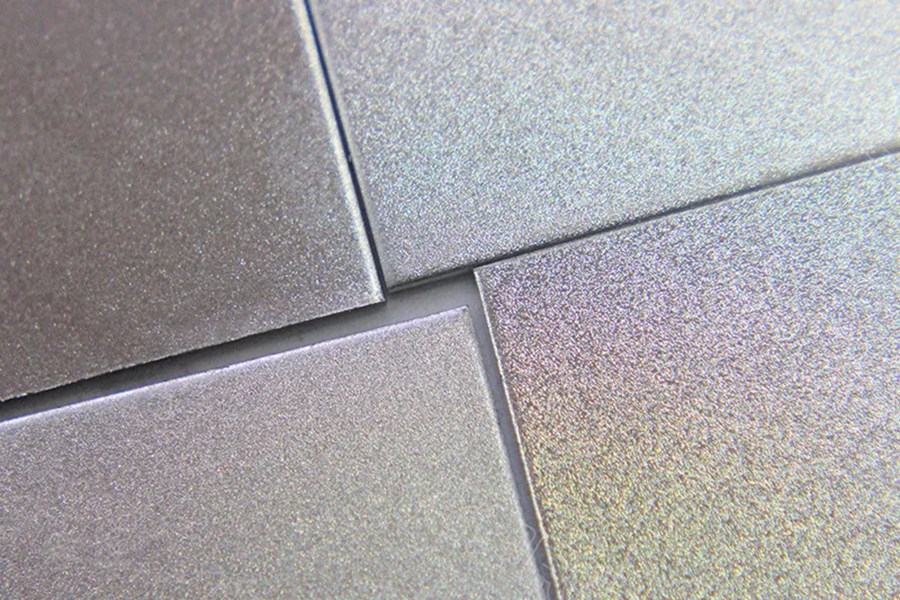

Bead Blasting

Bead blasting is the process of powerfully propelling, generally with high pressure, a stream of blast media against a surface to remove unwanted coating layers and surface impurities.

Aluminum, Steel, Stainless Steel, Brass, Copper

Anodizing

Keeping our parts in the long term, our anodizing process resists corrosion and wear. It's also an ideal surface treatment for painting and priming, and it looks great too.

Applicable materials: Aluminum

Electroplating

Electroplated coating preserves the surface of parts and resists rusts and other defects from causing decay by applying electric currents to reduce metal cations.

Applicable materials: Aluminum, steel, stainless steel

Polishing

Ranging from Ra 0.8~Ra0.1, polishing processes use an abrasive material to rub the part's surface to make the shine more less shiny, depending on your requirements.

Applicable materials: All materials

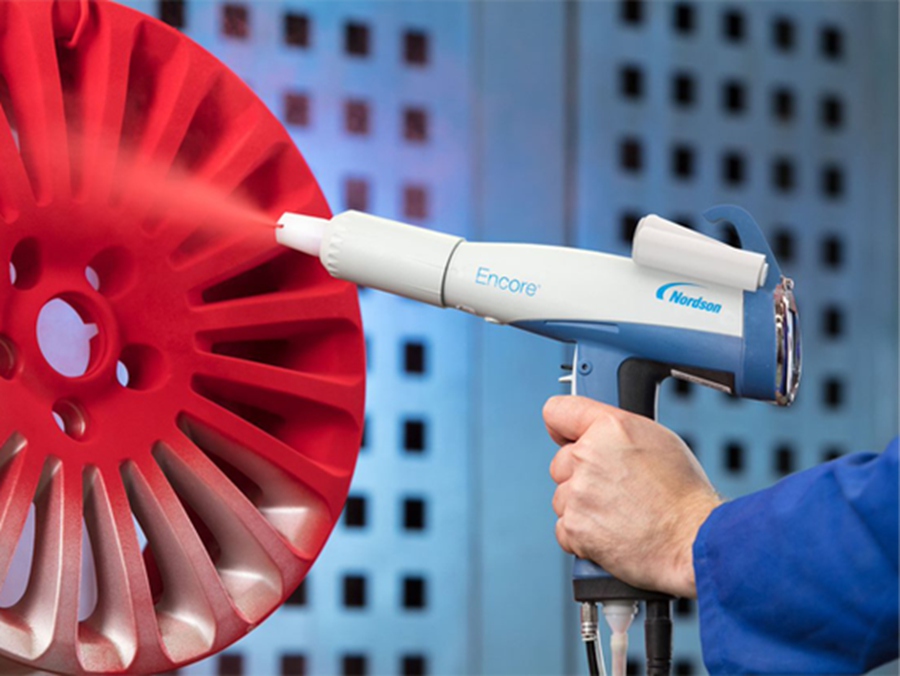

Powder Coating

Using corona discharge, we make the powder coating adsorbed to the part, creating a more wear-resistant layer with a typical thickness ranging from 50 μm up to 150 μm.

Applicable materials: All metal materials

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

Applicable materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Painting

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer's choosing, while finishes range from matte to gloss to metallic.

Applicable materials: Aluminum, Stainless Steel, Steel

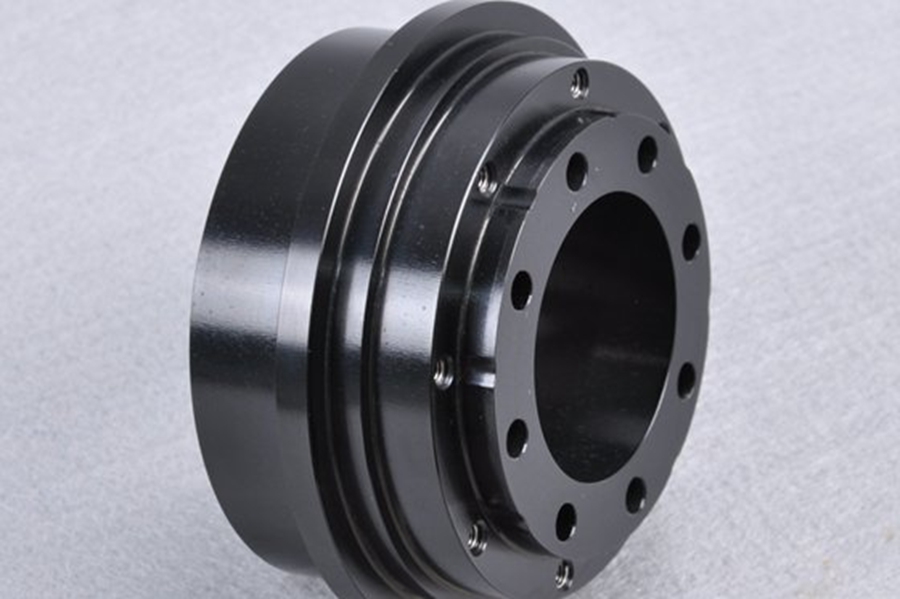

Black Oxide

Black oxide is a conversion coating similar to Alodine that is used for steel and stainless steel. It is used mainly for appearance and for mild corrosion resistance.

Applicable materials: Steel, Stainless Steel

Alodine

Chromate conversion coating, more commonly known by its brand name Alodine, is a chemical coating that passivates and protects aluminum from corrosion. It is also used as a base layer before priming and painting parts.

Applicable materials: Aluminum

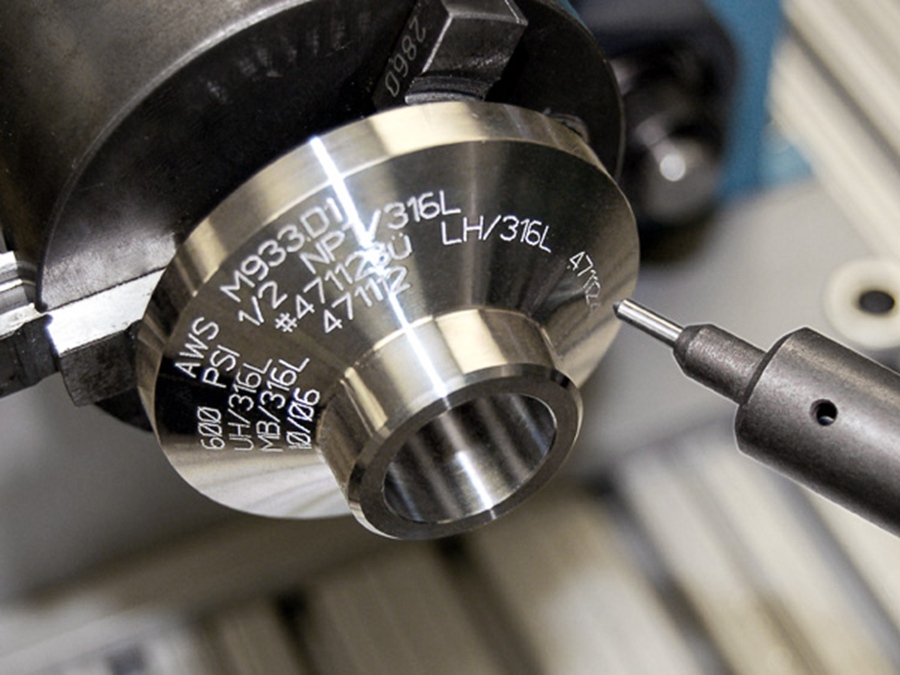

Part Marking

Part marking is a cost-effective way to add logos or custom lettering to your designs and is often used for custom part tagging during full-scale production.

Applicable materials: All materials

Related Knowledge