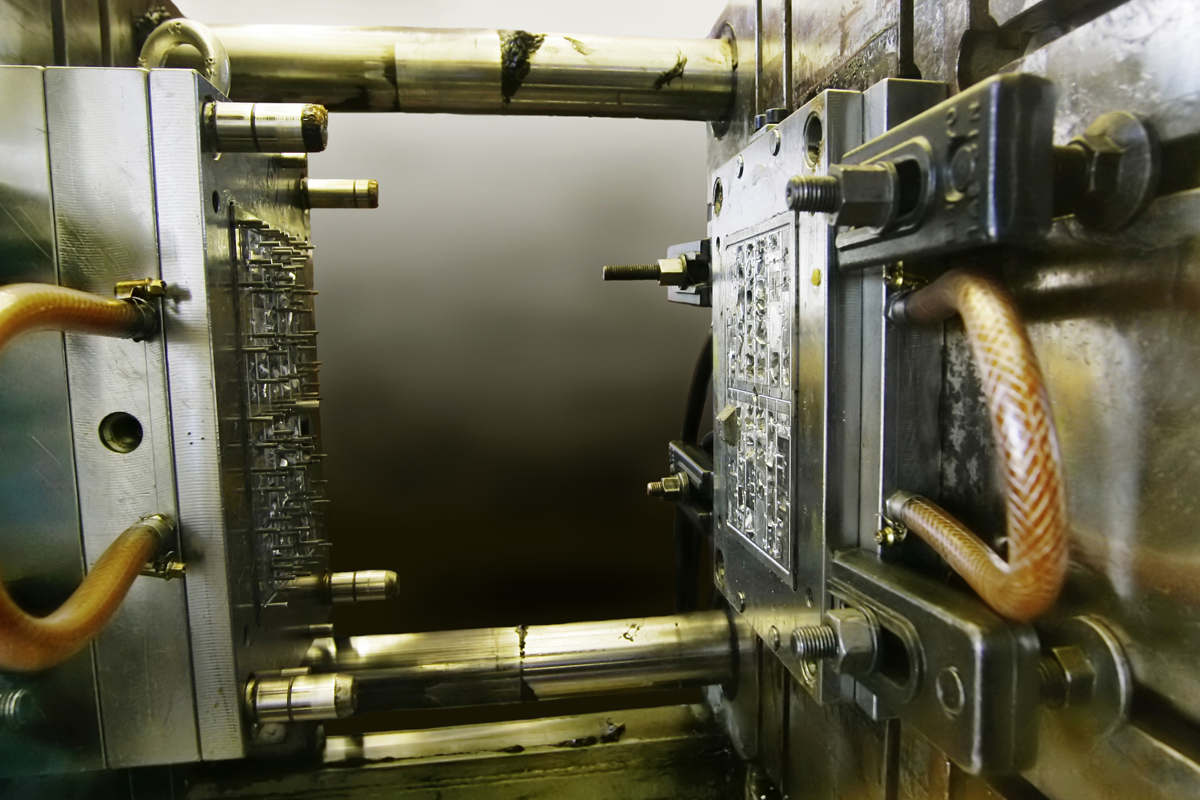

Injection moulding is used to manufacture plastic parts for a wide range of industries and this precision manufacturing process is very cost effective and can be achieved in Low Volume.

The importance of selecting the right injection molding material cannot be overstated. It can make or break the success of your product. This guidebook is designed to help you of low pressure overmolding material selection, providing you with the basics knowledge you need to make informed decisions.

Thermoplastics | Thermosetting Plastics | Elastomers | Composites | Biodegradable Materials | Other Materials |

Polypropylene (PP) | Phenolic | Styrene-Butadiene Rubber (SBR) | Glass Fiber Reinforced Plastics (GFRP) | Polylactic Acid (PLA) | Metal Injection Molding (MIM) materials (e.g., stainless steel, titanium alloys) |

Polyethylene (PE) | Epoxy | Ethylene Propylene Diene Monomer (EPDM) | Carbon Fiber Reinforced Plastics (CFRP) | Polyhydroxyalkanoates (PHA) | Ceramic-filled materials |

Acrylonitrile Butadiene Styrene (ABS) | Urea formaldehyde | Thermoplastic Elastomers (TPE) | Aramid Fiber Reinforced Plastics (AFRP) | Starch-based materials | Liquid Silicone Rubber (LSR) |

Polystyrene (PS) | Melamine formaldehyde | Silicone | Polybutylene Succinate (PBS) | Conductive plastics (e.g., carbon-filled materials) | |

Polyvinyl Chloride (PVC) | Unsaturated Polyester | Polyhydroxybutyrate (PHB) | High-temperature materials (e.g.,polyetherimide,polyphenylsulfone) | ||

Polycarbonate (PC) | Polyurethane (thermosetting type) | Polycaprolactone (PCL) | |||

Polyamide (Nylon) | |||||

Polyethylene Terephthalate (PET) | |||||

Polyoxymethylene (POM) or Acetal | |||||

Polyphenylene Sulfide (PPS) | |||||

Polyether Ether Ketone (PEEK) | |||||

Polyetherimide (PEI) | |||||

Polysulfone (PSU) | |||||

Polyphenylene Oxide (PPO) | |||||

Thermoplastic Polyurethane (TPU) | |||||

Polybutylene Terephthalate (PBT) | |||||

Polyether Block Amide (PEBA) | |||||

Polymethyl Methacrylate (PMMA) | |||||

Liquid Crystal Polymers (LCP) | |||||

Polyvinylidene Fluoride (PVDF) |

Importance of Tolerance in Injection Molding: What You Need to Know

Geometric Tolerances: Geometric tolerances define the allowable variations in specific dimensions, features, and geometrical relationships. They can include parameters such as linear dimensions, angles, concentricity, parallelism, flatness, and perpendicularity.

General Tolerance Ranges: As a general guideline, standard tolerances for injection mold tooling typically range from ±0.05 mm to ±0.2 mm (±0.002 inches to ±0.008 inches). However, it's important to note that these ranges can vary depending on the part size, complexity, material selection, and specific manufacturing capabilities.

Wall thickness depends on the material

Material | Wall Thickness (inches) |

ABS | 0.045 – 0.140 |

Acetal | 0.030 – 0.120 |

Acrylic | 0.025 – 0.500 |

Liquid Crystal Polymer | 0.030 – 0.120 |

Long-fiber reinforced plastics | 0.075 – 1.000 |

Nylon | 0.030 – 0.115 |

Polycarbonate | 0.040 – 0.150 |

Polyester | 0.025 – 0.125 |

Polyethylene | 0.030 – 0.200 |

Polypropylene Sulfide | 0.020 – 0.180 |

Polypropylene | 0.025 – 0.150 |

Polystyrene | 0.035 – 0.150 |

Polyurethane | 0.080 – 0.750 |

When you choose injection molding, you have to attention several important factors to look for to ensure successful and efficient production.

Design for Manufacturability: Pay attention to the design of the part or product being molded. Optimize the design for manufacturability by considering factors such as draft angles, wall thickness, gating and venting, parting lines, and features like ribs or fillets. A well-designed part reduces manufacturing challenges and improves overall quality.

Material Selection: Choose the appropriate material for your application based on the desired properties, such as strength, flexibility, chemical resistance, heat resistance, and appearance. Consider factors like material compatibility with the insert molding process, cost, and availability.

Mold Design: Ensure the mold design is precise and robust. It should allow for efficient filling, cooling, and ejection of the part. Proper venting, gating, and runner system design are crucial for achieving high-quality molded parts. Collaborate with experienced mold designers or toolmakers to optimize the mold design.

Mold Material and Construction: Select the right mold material based on factors like the expected production volume, material being molded, and required tool life. Common mold materials include steel and aluminum. Additionally, consider factors like mold cooling system design and surface treatments to enhance mold performance and longevity.

Post-Molding Processes: Consider any necessary post-molding processes such as secondary operations (e.g., assembly, painting, or decoration) and part finishing requirements. Ensure that injection moulded parts can be post-processed efficiently without compromising on quality.

Find a reliable manufacturer partner to complete your project

Choose a reputable injection moulding manufacturer with industry experience and a track record of delivering high quality parts. Evaluate their capabilities, equipment, quality systems, and adherence to industry standards. And GD-HUB fully meets all of these criteria. We have 10+ years of extensive experience in prototype manufacturing across a wide range of industries, so trust us to turn your design vision into a perfect reality!

Related Knowledge