9001:2005

CERTIFICATED

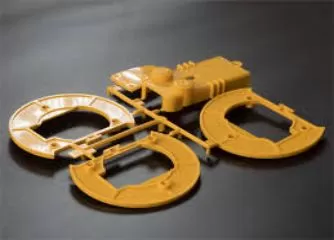

INJECTION MOLDING

MACHINES 30+

INJECTION PARTS

MADE MONTHLY 10000000+

MATERIAL

PLASTIC 100+

Plastic injection molding service is an efficient and cost-effective industrial process for precision manufacturing and widely used in:Automotive industry: manufacture of automotive interior and exterior parts, instrument panels, trays;Consumer electronics: manufacturing mobile phone cases, TV remote controls, computer parts;Medical equipment: manufacturing disposable medical supplies, diagnostic equipment parts;Household products: various containers, toys, tool handles, etc. The production of plastic products. This makes it a popular choice for low-cost market testing and rapid mass production in many industries. It involves the injection of molten plastic material under pressure into a pre-designed mold cavity, which is cooled and cured to obtain a plastic part of the desired shape. This method is suitable for mass production of plastic products of various sizes, shapes and complexity.

Why Choose GD-HUB’s Plastics Injection Molding

We understand that not every customer needs large quantities of injection molded prototypes. That's why we offer small batch custom prototype injection molding services even though 1 piece .Unlike other injection molding manufacturers that set high minimum order quantities, we are committed to providing you prototypes on you demand. The GD-HUB team performs rigorous quality checks on each of your injection molded prototypes before shipping to ensure your satisfaction. Choose us for personalized and efficient service, and trust that GD-HUB will take your project seriously and deliver exceptional results every time. No matter how demanding your needs are, we can promise to deliver your design vision with the highest quality.

ISO certified

ISO certified

Low Volume

Low Volume

Injection Parts with Tight Tolerances (±0.01mm)

Injection Parts with Tight Tolerances (±0.01mm)

Fast delivery: 3-15 days (depending on project requirements)

Fast delivery: 3-15 days (depending on project requirements)

24H/7d Engineering Support

24H/7d Engineering Support

Capabilities of GD-HUB Injection Molding

GD-HUB's wide range of injection molding services include plastic injection molding, custom injection molding, overmolding and insert molding. Our one-stop injection molding solutions make us your first choice for producing rapid prototypes and high quality injection molded products. With low MOQs starting at 1 piece, competitive pricing and fast lead times starting at 3 days, GD-HUB stands out from other plastic injection molding manufacturers in the industry.

Plastic Injection Molding

With GD-HUB's manufacturing experience and advanced machinery, we specialize in designing and manufacturing a series of Plastic Injection Molds adjusted to your tolerance and cost.

Our Plastics Injection Molding process uses precise machinery to inject the molten material needed to produce the part into the mold to produce the final production-grade thermoplastic part.

Overmolding

Covering plastic, metal, and rubber over each other via chemical bonding, GD-HUB's overmolding improves part function, durability, aesthetics, and reduces assembly time and cost.

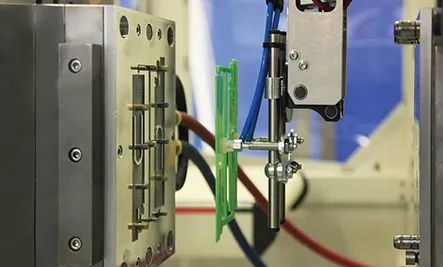

Insert Molding

Insert molding is a process of injection molding where a pre-formed part or component is placed into a mold, and molten material is injected around it, forming a single, integrated part. GD-HUB also provide Insert Molding services to manufacturing perfect prototypes with your project.

Processable Materials

GD-HUB's Custom Plastic Injection Molding services offer a variety of processable materials to meet your specific needs. Our services are compatible with a wide range of plastic materials, including Polyethylene (PE), Polypropylene (PP), Polystyrene (PS), PMMA, POM, PBT, PVC, PC/ABS, Acrylonitrile Butadiene Styrene (ABS), Polycarbonate (PC), and Nylone (PA). To determine which material is best suited for your project, please refer to our material list or contact us directly to discuss your unique requirements.