5 Importances of 3D Printing in Advancing Medical Research:

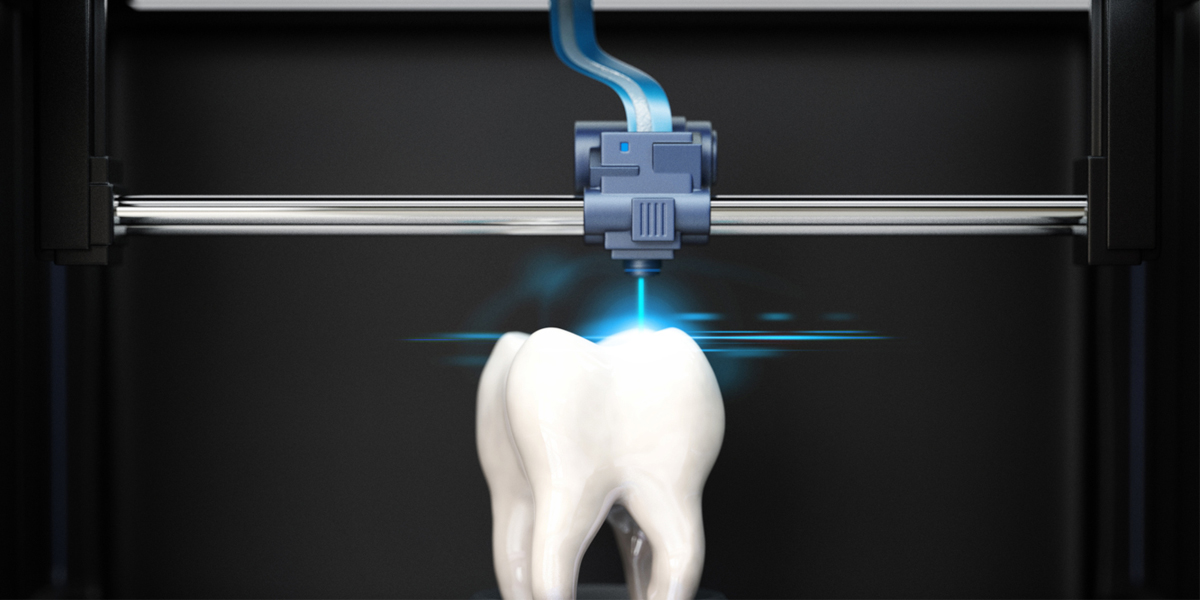

Customization and personalization: 3D printing allows for the creation of personalized medical devices and implants, tailored to individual patients. This customization improves treatment outcomes by ensuring better fit, improved functionality and enhanced patient comfort. Examples of this include patient-specific prosthetics, orthopedic implants, and dental implants.

Surgical planning and training: 3D printed anatomical models derived from patient-specific imaging data aid in surgical planning and training. Surgeons can practice complex procedures on accurate 3D models, improving their skills and reducing surgical risk. These models also facilitate communication between the surgical team and the patient, allowing for better preoperative discussions and informed decision-making.

Medical education and training: 3D printing can be used to teach physical models of anatomy, pathology and surgical techniques, facilitating enhanced medical education. Medical students and professionals can gain hands-on experience with realistic 3D printed replicas of organs and structures to better understand and develop skills.

Rapid prototyping and iterative design: 3D printing enables rapid production of prototypes, allowing for iterative design improvements. Medical devices and equipment can be rapidly developed, tested and refined prior to mass production. This speeds up the innovation process and shortens the time to market for new medical devices.

Bioprinting and Tissue Engineering: 3D bioprinting has tremendous potential for tissue engineering and regenerative medicine. It enables the precise placement of live cells, biomaterials and growth factors to create complex functional tissues and organs. This technology paves the way for advances in organ transplantation, drug testing, disease modeling and personalized medicine.

Steps in 3D printing:

Designing a 3D model: The first step is to create a digital 3D model of the object you want to print. This can be done using computer-aided design (CAD) software or by scanning an existing object using a 3D scanner. The model defines the shape, size and geometry of the object.

Slicing: Once the 3D model is ready, the next step is to prepare it for printing. This involves slicing the digital model into thin cross-sectional layers, which is usually done using slicing software. Each layer represents a physical slice upon which the 3D printer will print.

Selecting the print material: Depending on the requirements of the object to be printed, the appropriate print material is selected. A variety of materials are used in 3D printing, including plastics, metals, ceramics, resins, and even living cells in the case of bioprinting.

Prepare the 3D printer: Set up the 3D printer by selecting the desired printing parameters, such as layer thickness, printing speed and temperature. Load the print material into the printer, whether it is in the form of filament, powder or liquid resin.

Print the object: After doing the printer preparation, the printer first deposits or cures the first layer of the object based on the slice data. It then builds subsequent layers, layer by layer, according to the instructions provided by the digital model.

Post-processing: After printing, the object may require some post-processing steps. This may include removing the support structure (if used), cleaning excess material, and performing any necessary surface treatments such as sanding, polishing, or painting to achieve the desired effect.

Quality control and inspection: The 3d printed part should undergo quality control and inspection to ensure that it meets the required specifications. This may involve checking the dimensions, structural integrity and functional aspects of the printed object.

The process of 3D printing can vary depending on the specific technology used, such as fused deposition molding (FDM), stereolithography (SLA), selective laser sintering (SLS), or others. Each technology has its own unique procedures and considerations, but the general concept of layer-by-layer additive manufacturing is consistent across most 3D printing processes.

Some key aspects of the 3D printing process to consider:

Design and modeling: The quality of a 3D printed object is heavily influenced by the initial design and modeling stages. Creating a precise and accurate digital model using CAD software or 3D scanning technology is critical. Proper design considerations include wall thickness, support structure, tolerances, and geometric complexity.

Material Selection: Choosing the proper material for 3D printing is critical as it affects the properties and characteristics of the printed object. A variety of materials are available, including plastics, metals, ceramics, resins, and composites. Factors to consider include strength, flexibility, durability, heat resistance, biocompatibility (if applicable), and desired surface finish.

Printing Parameters: Setting the correct printing parameters is critical to achieving desired results. This includes selecting the proper layer thickness, print speed, temperature and fill density (for FDM). Optimizing these parameters ensures proper layer-to-layer adhesion, minimizes defects, and maximizes print quality.

Support Structures: Depending on the geometry and overhang of the object being printed, support structures may be required to provide stability during printing. These structures help prevent sagging or collapse of unsupported areas. Proper placement and removal of support structures helps improve the overall quality of the printed object.

Post-processing: After printing is complete, post-processing steps may be required to refine the print. This may involve removing support structures, cleaning excess material, sanding or polishing the surface, applying coatings or finishes, or performing additional treatments to improve aesthetics or functionality.

Quality control and testing: It is important to perform quality control checks and tests on 3D printed objects to ensure they meet the expected specifications. This can include dimensional accuracy checks, structural integrity assessments, functional testing, and surface quality assessments.

Workflow and Iterative Improvement: Developing an efficient workflow and iterative improvement process can help streamline the 3D printing process. This includes evaluating the entire process from design to post-processing, identifying potential bottlenecks or areas for optimization, and continuously refining the process to improve efficiency, accuracy, and overall output quality.

How many ways are there to 3d printing? What is the difference?

Fused Deposition Modeling (FDM): FDM is one of the most popular 3D printing technologies. It works by melting and extruding a thermoplastic filament through a heated nozzle. The material is then deposited layer by layer to create the object. FDM is known for its accessibility, affordability, and versatility, making it widely used for prototyping, hobbyist projects, and functional parts.

Stereolithography (SLA): SLA utilizes a liquid resin that is cured using a UV laser or light source. The object is created by selectively solidifying the resin layer by layer. SLA produces highly detailed and accurate prints, making it suitable for applications such as dental models, jewelry, and high-resolution prototypes.

Selective Laser Sintering (SLS): SLS involves using a high-powered laser to selectively fuse powdered materials, typically plastics or metals. The laser scans and sinters the powder particles together to form each layer of the object. SLS is known for its ability to produce complex geometries and functional parts, making it useful in industries like aerospace, automotive, and medical.

Digital Light Processing (DLP): DLP is similar to SLA in that it uses a liquid resin that is cured layer by layer. However, instead of a laser, it utilizes a digital light projector to cure the resin with UV light. DLP is known for its speed and high-resolution prints, making it suitable for applications such as jewelry, dental models, and rapid prototyping.

Binder Jetting: Binder Jetting involves selectively depositing a liquid binding agent onto a powdered material layer by layer. The binder solidifies the powder, creating the object. Binder Jetting can be used with a variety of materials, including metals, ceramics, and sand. It is commonly used for producing metal parts, sand casting molds, and architectural models.

PolyJet: PolyJet technology works by jetting layers of liquid photopolymer that are then instantly cured using UV light. It can also combine different materials and colors in a single print. PolyJet produces high-resolution prints with smooth surfaces, making it suitable for applications such as prototypes, consumer goods, and medical models.

Choosing a good service provider for your 3D printing project is critical to ensuring the quality of your prints. A good service provider will have high quality printers and use the best materials to produce accurate, durable and high resolution prints.

- Good customer service and support ensures that you have a smooth and hassle-free experience throughout the project

- Access to a wide range of materials and technologies ensures that your project can be printed in the most suitable material and technology for your needs.Range of services including design assistance, prototyping and production runs.

-Cost-effective solutions to meet the needs of your project without compromising quality.

-Expertise and experience to provide guidance on design, materials and printing techniques to ensure the best results.

- Fast turnaround times ensure that your project is delivered on time and within budget