In a CNC turning process, the cutting tool, which is typically a non-rotary tool bit, describes a helical toolpath by moving more or less linearly while the workpiece rotates. The tool's motion across the workpiece may be described as a combination of rotation and linear movement.

①. How does CNC turning(CNC Lathe) work?

Programming: The first step in CNC turning is to create a program that defines the operations to be performed on the workpiece. This is usually done using a specialized software, where the operator defines the desired end shape of the workpiece. This program then translates these instructions into a language (G-code) that the CNC machine can understand.

Setting Up the Machine: Once the program is ready, the operator needs to set up the CNC machine for the job. This involves mounting the workpiece onto the spindle and securing it with the chuck, and installing the necessary tooling into the tool turret.

Starting the Operation: After the workpiece and tools are set, the operator will load the G-code program into the CNC machine and start the operation. The machine will then automatically perform the turning operations as specified in the program.

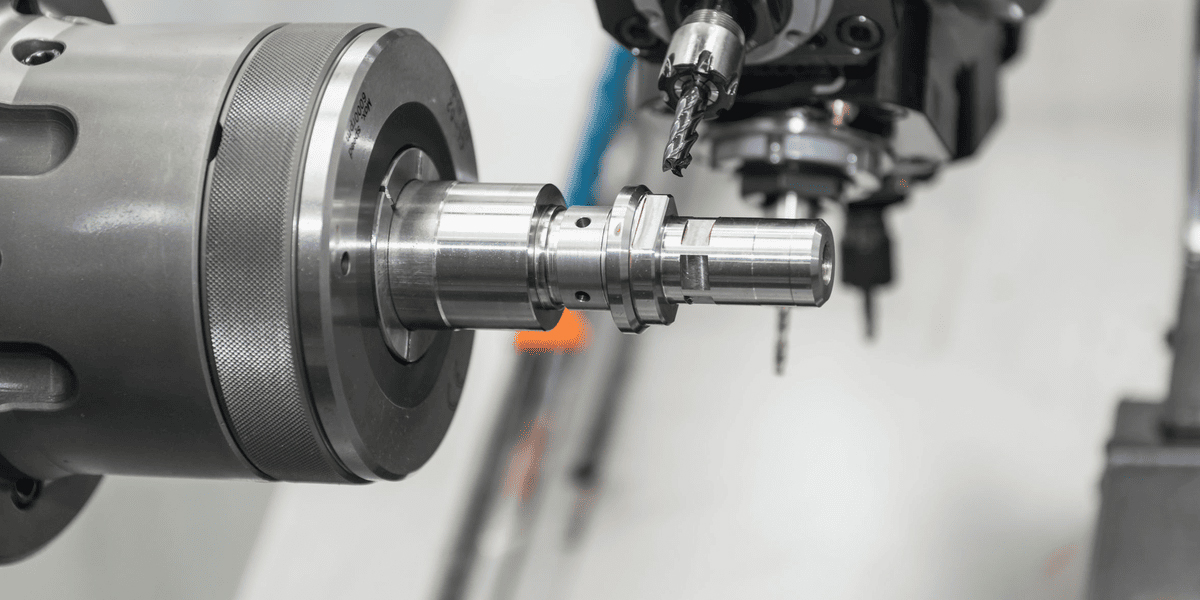

Workpiece Rotation and Tool Movement:

The CNC turning machine holds the workpiece in place with a device known as a chuck while the workpiece is being turned (rotated). Simultaneously, the CNC machine moves the cutting tool, which is held in the tool turret, along various axes as instructed by the G-code program. This precise movement of the tool cuts away material from the workpiece, shaping it into the desired form.

Inspection and Finishing: After the machine has finished turning the workpiece, the operator will usually inspect the piece to ensure it matches the specifications outlined in the program. Any finishing touches, like sanding or polishing, can then be applied if necessary.

②. Different CNC turning operations include:

Straight turning: This is a process where the cutting tool moves along the length of the workpiece, reducing its diameter.

Tapered turning: The cutting tool is angled to create a taper along the length of the workpiece.

Profiling: A complex tool path is followed to create complex contours on the surface of the workpiece.

External grooving: A groove is cut into the outer surface of the workpiece.

Drilling: Holes are bored into the workpiece. This can be done with the workpiece in any orientation in relation to the tool.

Boring: This process enlarges a hole or cavity produced by a previous process or creates a hole in a solid material.

Threading: The process of creating a screw thread.

③. Feed rate, speed, and depth of cut are all important parameters that affect the quality of the turned part.

Feed rate, in the context of machining and CNC turning, refers to the speed at which the cutting tool moves through the material being cut. It's often measured in units of distance per revolution (such as millimeters per revolution, mm/rev) or distance per minute (such as inches per minute, ipm or millimeters per minute, mm/min).

The feed rate is one of the critical parameters in machining operations, affecting both the machining time and the quality of the finished product.

A high feed rate speeds up the machining process, reducing the time it takes to complete a part. However, this can lead to a rougher finish on the material and may cause greater wear and tear on the cutting tool.

A slower feed rate can result in a finer, higher-quality finish and less tool wear, but it takes longer to complete the machining process.

Depth of cut in machining and CNC turning refers to the distance that the cutting tool penetrates into the surface of the workpiece. It's usually measured in units of length, such as millimeters or inches. The depth of cut is one of the key parameters in machining operations that significantly influences both the machining time and the quality of the finished product.

The selection of the depth of cut affects the material removal rate, the forces and heat generated in the cutting zone, tool life, and the surface finish of the workpiece.

A larger depth of cut can increase the material removal rate, thereby reducing the machining time. Lead to higher cutting forces, increased heat generation, a rougher surface finish, and faster tool wear.

Smaller depth of cut will lead to a finer surface finish and longer tool life but will increase machining time due to the decreased material removal rate.

④. Some features of the CNC turning process:

Precision: The CNC turning process is highly precise, capable of producing parts to exact specifications with very tight tolerances.

Repeatability: The process can produce the same part repeatedly with high consistency. This makes it ideal for mass production.

Versatility: The CNC turning process can be used to machine a wide variety of materials, including different types of metal, plastic, and even wood.

Complex Shapes: It's capable of producing complex shapes and geometries that may be difficult or impossible to achieve with manual machining. The tool can be moved in multiple axes to create intricate designs.

Automated Operation: The CNC turning process is largely automated. Once the program is inputted into the machine and the workpiece is set up, the machine can carry out the turning operation with minimal human intervention.

Speed: The CNC turning process is generally faster than manual turning, particularly for complex or large-volume jobs.

Integration with CAD/CAM: CNC turning machines can be integrated with CAD/CAM software, allowing for a seamless transition from digital design to physical part.

Predictability: The process is highly predictable, as the CNC program will execute in the same way every time, assuming the machine is properly maintained and set up. This allows for reliable estimation of production times.

GET MORE FREE CNC TECH INFORMATION CLICK HERE ↓