Stereolithography (SLA) is an additive manufacturing process belonging to the family of reduced light polymerization. In SLA, objects are produced by selectively curing a polymer resin layer by layer using an ultraviolet (UV) laser beam.The materials used in SLA are light-sensitive thermosetting polymers in liquid form.

The light-curing molding process, also often referred to as stereolithography, is known as StereoLithography, or SL, or sometimes abbreviated as SLA.

It was the first method of 3D printing to be developed and is considered the pioneer of the whole additive manufacturing industry.

①. A general outline of how SLA printing works:

Designing the 3D Model: Like all 3D printing processes, it begins with designing a 3D model on a computer, usually through CAD software.

Slicing: The design is then "sliced" into thin, horizontal cross-sections using specific slicing software. This software also converts the 3D model into a set of instructions for the printer to follow.

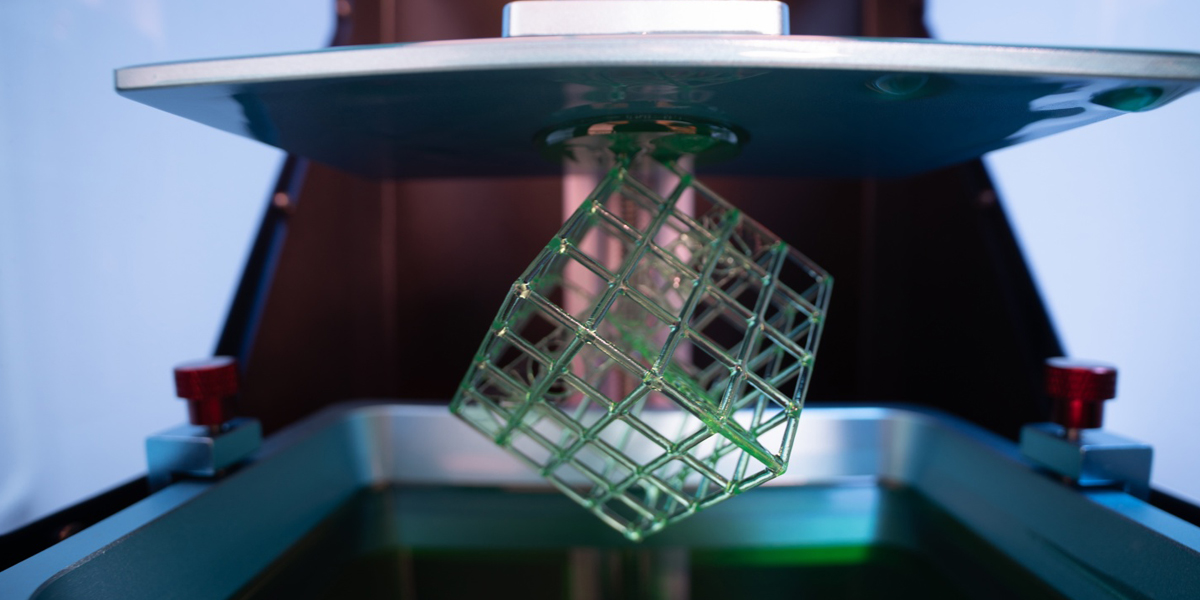

Printing: The 3D printer starts with a vat of liquid photopolymer resin. Using a UV laser, the printer draws the first layer of the 3D object onto the surface of this liquid resin, curing and hardening it. The laser is guided by the instructions generated by the slicing software.

Layering: After the first layer is completed, the build platform moves slightly up (or down, depending on the machine configuration), allowing a new layer of resin to flow under the just cured layer. The laser then traces and cures the next layer. This process is repeated until the object is completed, layer by layer.

Post-processing: Once the object is printed, it is typically rinsed with a solvent to remove excess resin, and then baked in a UV oven (or exposed to sunlight) to fully cure the resin and solidify the object.

②. Design Specifications:

In the "3D printing data model of experience sharing" mentioned the reality of no thickness does not exist, so in the design should pay attention to the detail structure of the model, SLA process detail structure requirements are generally:

(1) Minimum detail wall thickness: 0.6mm (the thickness of the large thin section should be greater than 2mm);

(2) Minimum independent column diameter: 1mm;

(3) Minimum convex (concave) stroke width: 0.35;

(4) Minimum hole diameter: 1mm;

(5) Minimum gap: 0.4mm;

③.Advantages of SLA 3D Printing:

High Resolution and Accuracy: SLA printing can produce objects with very fine details and a smooth surface finish. This is due to the small size of the point of the UV laser, which can be controlled very precisely.

Complex Geometries and Intricate Designs: SLA printers can produce parts with complex geometries that may not be feasible with other types of 3D printing. This makes it ideal for creating intricate designs, such as jewelry or architectural models.

Wide Range of Materials: SLA printers use a variety of photopolymer resins, each with different properties, such as flexibility, strength, temperature resistance, and even colors.

Fast Prototyping: SLA printing is relatively fast for producing small, detailed prototypes, making it ideal for design iterations and testing.

④. Disadvantages of SLA 3D Printing:

Cost of Materials: SLA resins can be expensive compared to other 3D printing materials, such as filament used in FDM printers.

Post-Processing: SLA printed parts usually require extensive post-processing, including washing, curing, and removal of support structures. This can be time-consuming and requires additional equipment.

Durability: While SLA parts can be quite strong, they can also be brittle depending on the resin used. Additionally, parts can degrade if exposed to UV light over time.

Size Limitations: SLA printers generally have a smaller build volume compared to other types of 3D printers like FDM. This means that larger parts need to be printed in sections and then assembled.

Safety and Handling: SLA resins are chemicals that need to be handled with care. They can be harmful or irritant, requiring safety equipment when handling. The liquid resin also needs to be stored properly to prevent degradation.

⑤. Stereolithography (SLA) 3D printing uses a variety of liquid resin materials. The choice of resin greatly affects the performance of the final printed object:

Standard Resins:

The most common types of resins used in SLA printing. They offer a good balance of cost and performance and are suitable for general purpose applications.

Engineering Resins:

These specialized resins have specific mechanical properties such as high strength, flexibility, or temperature resistance. They are often used for functional parts and prototypes. Toughness resins (for strong and durable parts), durability resins (for parts that require impact resistance and flexibility), and high-temperature resins (for parts that need to withstand high temperatures).

Castable Resins:

Used to make molds for the jewelry and dental industries.

Medical and Dental Resins:

These are biocompatible resins used in the production of medical and dental items such as surgical guides or orthodontic appliances.

Flexible Resins:

These resins produce parts that can be bent and compressed, similar to rubber. They are often used for parts that need to withstand strain and bending.

Ceramic Resins:

Ceramic resins produce parts with high temperature resistance and hardness characteristics.

Colored Resins:

Resins are available in a variety of colors. They are suitable for printing parts that require aesthetic appearance.

⑥. Stereolithography (SLA) is a powerful 3D printing technology, but like any other method, it encounters a variety of issues that can affect the quality of the final part:

Warpage and Shrinkage:

Due to the nature of the SLA process, printed parts can warp or shrink. This is usually due to a fast curing process, uneven curing, or incorrect calibration.

Solution: Calibration and careful monitoring of the print process can help minimize these problems.

Layer Peeling or Delamination:

This occurs when the layers of a print become separated from each other. This can be caused by a variety of reasons, such as incorrect print settings, improper resin handling, or mechanical problems with the printer.

Solution: Check the print settings to ensure that the resin is properly mixed and stored, and follow the instructions for maintaining the printer.

Incomplete or Failed Prints:

Occasionally, a print may not be completed as expected or may fail completely. This may be due to insufficient support, incorrect exposure settings, or problems with the resin canister.

Solution: Make sure the print has adequate support, check the exposure settings, and keep the resin canister clean and free of debris or damage.

Surface Defects:

SLA prints sometimes have small bumps, pits, or other surface defects. The problem may be caused by dust or debris in the resin, overcuring, or problems with the resin canister.

Solution: Keep the resin and resin canister clean, check the exposure settings and make sure the resin canister is in good condition.

Brittle Prints:

Sometimes SLA prints come out more brittle than expected. This may be due to problems such as insufficient curing, incorrect post-curing, or using a resin that is not suitable for the application.

Solution: Check the curing settings and post-curing process to ensure that the type of resin used is appropriate for the requirement.

Discoloration:

SLA prints sometimes discolor, either immediately after printing or over time. This can be caused by factors such as excessive exposure to UV light or the use of old or contaminated resins.

Solution: Store prints out of direct sunlight and make sure the resin is stored properly and has not exceeded its expiration date.

⑦. Difference between SLA(Stereolithography) and FDM(Fused Deposition Modeling),SLS(Selective Laser Sintering)

SLA (Stereolithography):

Uses a UV laser to cure and harden a liquid photopolymer resin, layer by layer.

Known for its high precision and smooth surface finish, allowing for the creation of parts with intricate details.

Often requires extensive post-processing, including washing, curing, and support removal.

Resins used in SLA can be relatively expensive and need careful handling due to their chemical nature.

FDM (Fused Deposition Modeling):

Extrudes a thermoplastic filament through a heated nozzle, depositing it layer by layer onto the build plate.

Widely accessible and relatively inexpensive, with a wide variety of filament materials available.

Generally not as precise as SLA or SLS, and printed parts may show visible layer lines.

Support structures, when required, can usually be removed more easily than those in SLA prints.

SLS (Selective Laser Sintering):

Uses a high-power laser to fuse small particles of polymer powder, building up the object layer by layer.

Can create complex and durable parts without the need for support structures.

The surface finish of SLS prints is typically rougher and more porous than SLA or FDM.

The process and materials can be expensive, making it less accessible for personal use or small businesses.

⑧. Development trend and prospect

SLA technology is mainly used to manufacture a variety of molds, models, etc.; it is also possible to replace wax molds in investment casting with SLA prototype molds by adding other components to the raw materials.SLA technology has a faster molding speed and higher precision, but due to the shrinkage of the resin during the curing process, it inevitably produces stress or causes deformation. Therefore, the development of small shrinkage, fast curing, high strength photosensitive materials is its development trend. The development trend of three-dimensional light-curing molding method is high-speed, energy saving and environmental protection and miniaturization. The ever-increasing processing precision makes it possible to make a big difference in the fields of biology, medicine and microelectronics.

⑨. Choosing the right 3D printing service provider is critical to the success of your project. Why choose GD-HUB:

Expertise and capabilities:

Different providers may have different levels of expertise and capabilities in terms of the 3D printing technologies they can offer. By choosing GD-HUB, we specialize in the technology you need (whether it's FDM, SLA, SLS, or something else), and we can ensure that we have the knowledge and experience to deliver high-quality results.

Material selection:

Depending on the project, specific materials may be required. Not all 3D printing services offer a wide range of material options, and GD-HUB's wide range of material choices gives you the flexibility to select the best material for your specific application.

Quality Assurance:

GD-HUB's reputation for good will be further enhanced by a quality assurance process that ensures the final product meets the required specifications and quality standards.

Lead Time:

The time it takes from placing an order to receiving a part can vary greatly from supplier to supplier. If you are working to a tight deadline, GD-HUB can deliver parts quickly.

Pricing:

Cost is always a consideration. Some suppliers may offer lower prices, but this may mean lower quality or longer lead times. At GD-HUB, it is important to balance cost with other factors to ensure you get the best value.

Customer Service:

Good customer service is critical, and GD-HUB offers 7/24 online technical support that includes clear communication, responsiveness to inquiries or questions, and a willingness to work with you to meet your needs.

Post-processing Services:

Some 3D prints require post-processing, such as support removal, sanding, or painting, and GD-HUB has the ability to provide you with these post-processing services.

Confidentiality:

If you are printing a part with a proprietary design, the GD-HUB will sign a non-disclosure agreement with you to manufacture your part in the most private process possible.