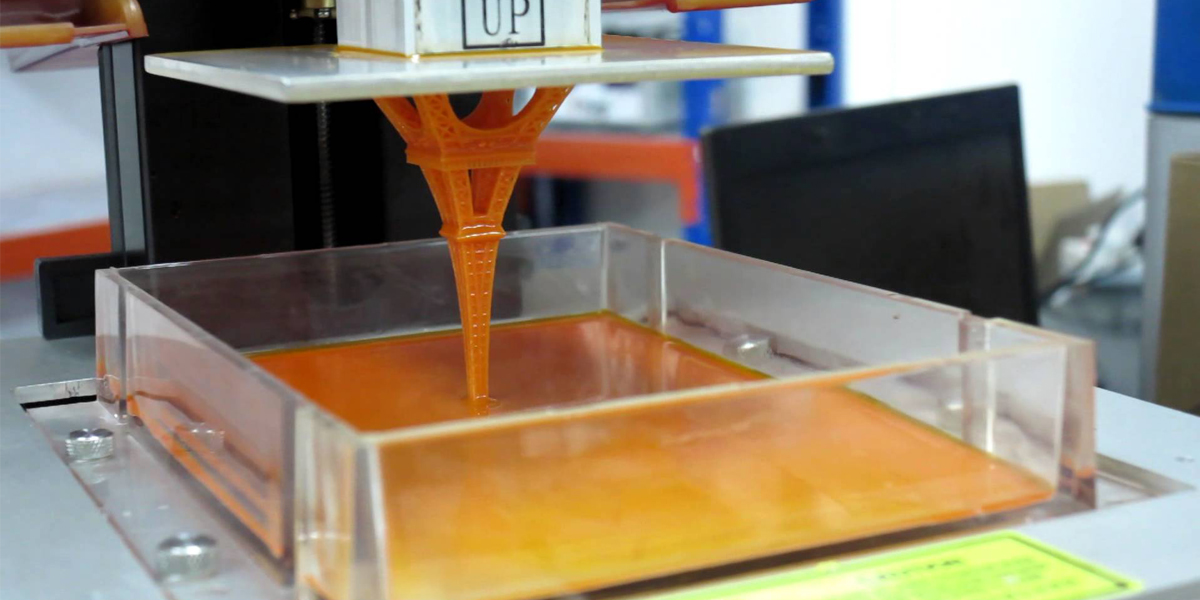

Stereolithography (SLA) is one of the forms of 3D printing technology that uses photosensitive liquid resins and ultraviolet (UV) lasers to create 3D objects layer by layer.

The main advantages that SLA brings to rapid prototyping:

High Resolution:

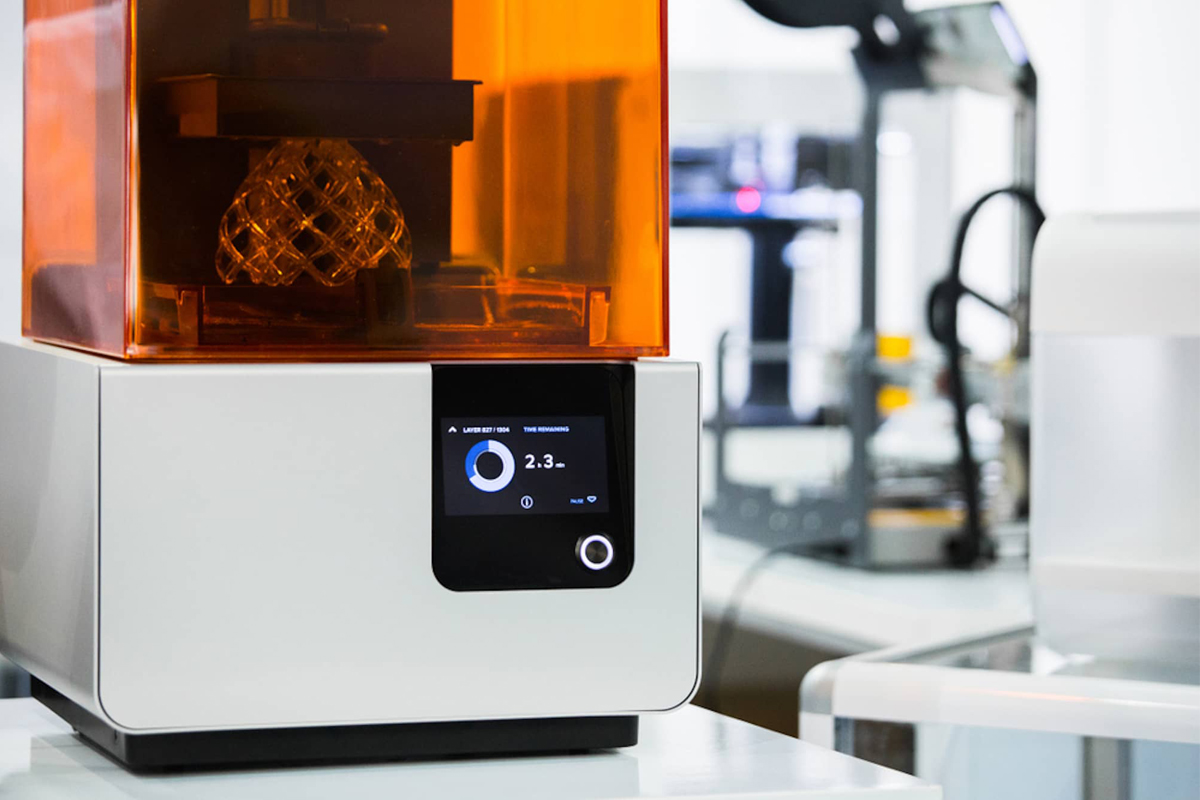

SLA 3D printers are known for their high resolution and accuracy. They can create parts with smooth surfaces and fine details that are difficult to achieve with other rapid prototyping technologies. This makes them ideal for creating prototypes that require high quality and visualization.

Speed:

SLA's ability to create prototypes relatively quickly allows designers to go from concept to physical model in a short amount of time. This speed can significantly reduce the time it takes to bring a product to market.

Material Versatility:

SLA printers can use a wide range of resin materials, resulting in a wide range of physical properties in the final product.

Design Complexity and Freedom:

SLA does not have many limitations in terms of geometric complexity. This means it is possible to create prototypes with intricate details, complex geometries and internal features. This provides greater freedom of design and the ability to prototype more advanced designs.

Cost-effective for small-volume production:

SLA 3D printing is more cost-effective for making small numbers of prototypes than other traditional manufacturing methods. This is because it does not require expensive molds or tooling.

Consistent:

SLA 3D printing provides consistent and repeatable results, which is critical for organizations that need to create multiple identical prototypes.

While SLA can provide excellent detail and accuracy, the durability and strength of SLA-printed parts may not be comparable to those produced using traditional manufacturing methods, which may limit their use in functional prototyping.

What SLA limitations do I need to be aware of for rapid prototyping?

Material Limitations:

SLA uses photopolymer resins, which, while versatile and able to mimic a wide range of materials, do not match the strength, durability, or heat resistance of many production-grade materials. This can limit functional testing of prototypes to some extent.

Post-processing:

SLA-printed parts typically require extensive post-processing. Removal from the build platform, removal of support structures, cleaning to remove excess resin, and curing under UV light to ensure full hardness.

Material Cost:

The resin used in SLA printing can be quite expensive compared to the filament materials used in Fused Deposition Modeling (FDM) or other types of 3D printing.

Size Limitations:

SLA printers are typically smaller than other types of 3D printers and are less suitable for printing large prototypes or parts.

Brittleness:

While SLA can produce parts with rich detail and smooth surfaces, the cured resin may be brittle and not hold up well to stress or impact. This limits its use in functional prototyping.

Limited color options:

Typically, SLA printers can only print the color of the resin currently in the machine, which means you can only print one color at a time.

Choose a professional and reliable 3d printing service provider, GD-HUB will meet all your needs.