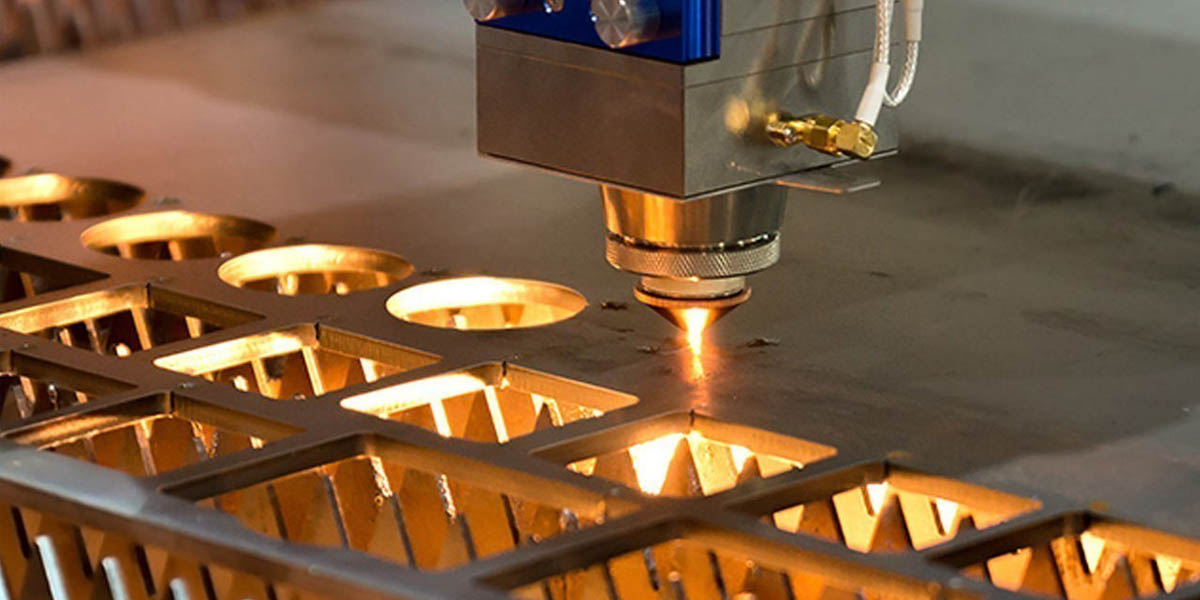

Ⅰ. —— What is Laser cutting?

Laser cutting is a technology that uses a laser to slice through materials. It's typically used for industrial manufacturing applications, but it's also starting to be used by schools, small businesses, and hobbyists.

The two primary types of lasers used for cutting are CO2 lasers and fiber lasers. CO2 lasers are used for cutting, boring, and engraving. They're used in many types of fabrication processes. Fiber lasers are a type of solid-state laser that is rapidly growing in popularity, particularly in metal cutting.

Advantages of laser cutting:

1. Precision:

Laser cutting offers high precision and accuracy. This is especially useful for intricate designs and patterns.

2. Speed:

It can be faster than manual cutting or machining processes.

3. Quality:

Laser cutting usually requires minimal after-process finishing because it leaves a very smooth edge.

4. Versatility:

It can cut a wide variety of materials, including metal, plastic, wood, ceramic, and glass. It can also cut different material thicknesses.

5. Non-contact:

As a non-contact cutting method, there's no tool wear, and material deformation due to physical contact is minimized.

Disadvantages of laser cutting:

1. Power Consumption:

Laser cutting machines usually consume a lot of power.

2. Cost:

The upfront cost of the equipment can be high.

3. Safety Concerns:

Special precautions need to be taken, such as wearing special eyewear, to ensure safety.

4.Limitations on Material Thickness:

While laser cutting can handle a wide range of materials and thicknesses, very thick materials may be challenging to cut through completely and cleanly.

5. Heat Affected Zone (HAZ):

Just like with plasma cutting, laser cutting introduces a heat-affected zone that can change the properties of the material being cut.

How laser cutting works?

Beam generation:

The laser beam is generated by stimulating the laser medium using a process called optical pumping. This energizes the atoms and produces a population inversion, i.e. more atoms are in the excited state than in the lower energy state.

Beam amplification:

The excited atoms emit photons, which trigger the emission of more photons through excitation emission. These photons bounce back and forth between mirrored surfaces within the laser medium, resulting in a chain reaction of amplified beams.

Beam Focusing:

The amplified laser beam is passed through a lens system that focuses it into a small, intense spot of light. This high-energy beam is directed to the material surface.

Material Interaction:

The focused laser beam rapidly heats, vaporizes or melts the material at the point of contact. The high energy density of the laser beam cuts the material along a predetermined path.

lGas Assisted Cutting:

In many cases, a gas, such as oxygen or nitrogen, is used in conjunction with the laser beam to aid in the cutting process. The gas will blow away the melted or vaporized material, creating a clean and precise cut.

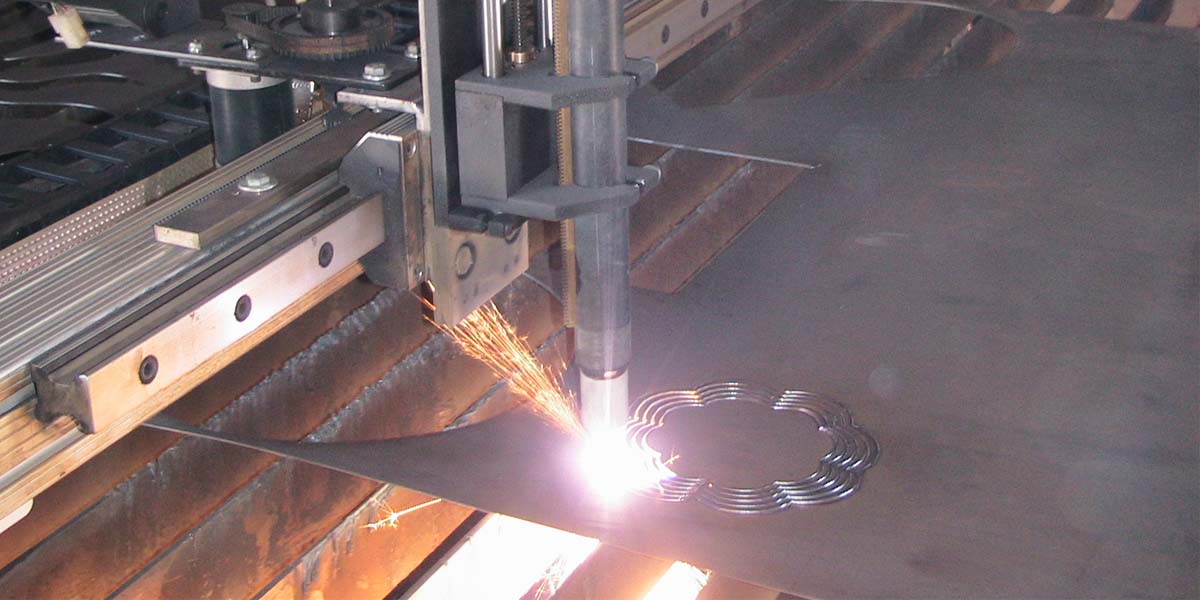

Ⅱ. —— What is Plasma Cutting?

Plasma cutting is a process that is used to cut steel and other metals (and sometimes other materials) of different thicknesses using a plasma torch. In this process, an inert gas (often compressed air) is blown at high speed out of a nozzle; at the same time, an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma.

The plasma is hot enough to melt the material being cut and blow the molten metal away from the cut at a fast enough rate. Plasma can also be used for plasma arc welding and other applications.

Advantages of plasma cutting:

1. Speed:

For thicknesses under 1 inch, plasma cutting is much faster than traditional torch cutting.

2. Quality:

Plasma cutting leaves smoother, more refined edges than torch cuts.

3. Versatility:

Plasma cutters can cut any conductive metal, including steel, stainless steel, aluminum, copper and brass. They are also capable of cutting a wide range of material thicknesses.

4. Accuracy:

Complex shapes and designs can be easily achieved with automated plasma cutting systems.

Disadvantages of plasma cutting:

1. Cost:

Plasma cutters are typically more expensive than other types of cutting equipment.

2. Noise and Fumes:

The plasma cutting process can be noisy and produce fumes, so adequate ventilation and hearing protection are necessary.

3. Heat Affected Zone:

Plasma cutting creates a heat affected zone (HAZ) that can change the properties of the material being cut.

4. Power Requirements:

Plasma cutters require a lot of power to operate effectively, which can limit their portability.

How Plasma cutting works?

Gas Ionization:

A gas, typically compressed air or an inert gas like nitrogen, is forced through a small nozzle at high velocity. This gas flow is directed toward the material to be cut.

Electric Arc Formation:

An electric arc is established between the nozzle and the material by passing a high-frequency electrical current through them. The electric arc ionizes the gas, forming a plasma.

Plasma Jet Creation:

The ionized gas, or plasma, reaches extremely high temperatures (up to 30,000°C) and forms a focused jet. The plasma jet is constricted by the nozzle, which maintains its coherence and directed force.

Material Melting and Blowing:

The intense heat of the plasma jet melts the material, and the high-velocity gas blows away the molten metal, creating a cut. The gas stream also protects the cut from oxidation.

Ⅲ. —— What is Water Jet Cutting?

Water jet cutting is a manufacturing process that uses very high-pressure water jets or a mixture of water and abrasive substances to cut a variety of materials.

The process works by passing a large amount of water under high pressure through a small hole or nozzle to form a concentrated water jet. If the material being cut is particularly hard, such as stone or metal, an abrasive material, such as garnet or aluminum oxide, is added to the water jet to assist in the cutting process.

Types of water jet cutting:

1. Pure water jet cutting:

This is mainly used for cutting softer materials such as rubber or foam. In this type, only water is used to cut the material without the addition of abrasives.

2. Abrasive water jet cutting:

This type is used to cut harder materials such as metal, stone or glass. The high pressure water jet mixes with the abrasive particles and helps in the cutting process.

Water jet cutting is valued for its ability to maintain the integrity of the material because it does not generate heat, deformation or mechanical stress during the cutting process. This is particularly useful in industries such as aerospace and automotive, where precision is critical.

Advantages of water jet cutting are:

1. It can cut complex shapes with a high degree of precision.

2. It does not require any heat treatment or finishing processes, reducing costs and lead times.

3. It is environmentally friendly because it produces no hazardous waste and the water used can be recycled.

4. It is safe because it does not produce any harmful fumes or dust in the air.

Disadvantages of water jet cutting:

1. Cost:

Water jet cutters are expensive to purchase and maintain. The cost of the abrasives used can also add to the cost of operation.

2. Speed & Taper:

Handling very hard or thick materials is slow compared to other methods such as laser or plasma cutting. The water and abrasive stream can widen slightly when cutting, resulting in a cut that is wider at the bottom than at the top, which is called taper.

3. Material and thickness limitations:

Very hard materials like tempered glass or certain types of ceramics can be difficult to cut accurately. Extremely thick materials may present challenges or require multiple cuts.

4. Noise:

The cutting process itself can be quite loud, and in some environments noise mitigation measures may be required.

5. Material warpage:

Although less common than thermal cutting methods, water jets can sometimes cause slight deformation or warpage of certain materials.

How Water Jet works?

High-Pressure Water Generation:

Water is pressurized to extremely high levels, typically between 30,000 and 90,000 pounds per square inch (psi), using a high-pressure pump.

Abrasive Mixing:

In some water jet systems, abrasive particles, such as garnet, are mixed with the pressurized water. The abrasive particles enhance the cutting efficiency by adding cutting power to the water stream.

Nozzle and Focusing:

The pressurized water or abrasive-water mixture is directed through a small orifice in a nozzle, creating a high-velocity jet. The nozzle can be equipped with focusing devices to control the shape and size of the jet.

Material Erosion:

The high-velocity water or abrasive-water stream strikes the material's surface, eroding and cutting through it. The erosion process is achieved through the abrasive action of the water stream or abrasive particles.

Differences between laser cutting, plasma cutting and water jet cutting:

Energy source:

Laser cutting uses a focused beam of light, plasma cutting uses a high-temperature plasma arc, and water jet cutting uses a high-pressure stream of water mixed with abrasive particles.

Materials:

Laser cutting is suitable for a wide range of materials, including metals, plastics, wood and fabrics. Plasma cutting is primarily used for electrically conductive materials such as steel, stainless steel and aluminum. Water jet cutting is versatile and can cut a wide variety of materials, including metals, stone, glass, ceramics and composites.

Accuracy:

Laser cutting offers excellent precision with narrow kerf widths and minimal heat-affected zones. Plasma cutting is relatively accurate, but can result in wider kerf widths and more significant heat distortion. Water jet cutting offers good accuracy but typically results in wider kerfs compared to laser cutting.

Cutting speed:

Laser cutting typically offers faster cutting speeds compared to plasma and water jet cutting. For thicker materials, plasma cutting is faster than water jet cutting, while for thinner materials, water jet cutting is faster.

Cutting thickness:

Laser cutting is effective for thin to medium thickness materials, while plasma cutting is suitable for medium to thick materials. Water jet cutting can handle a wide range of thicknesses, from thin to very thick materials.

Edge quality:

Laser cutting provides high quality, clean edges with minimal burrs. Plasma cutting produces beveled edges with some roughness and dross formation. Water jet cutting provides a smooth edge finish, but the presence of abrasive particles leaves a rougher surface.