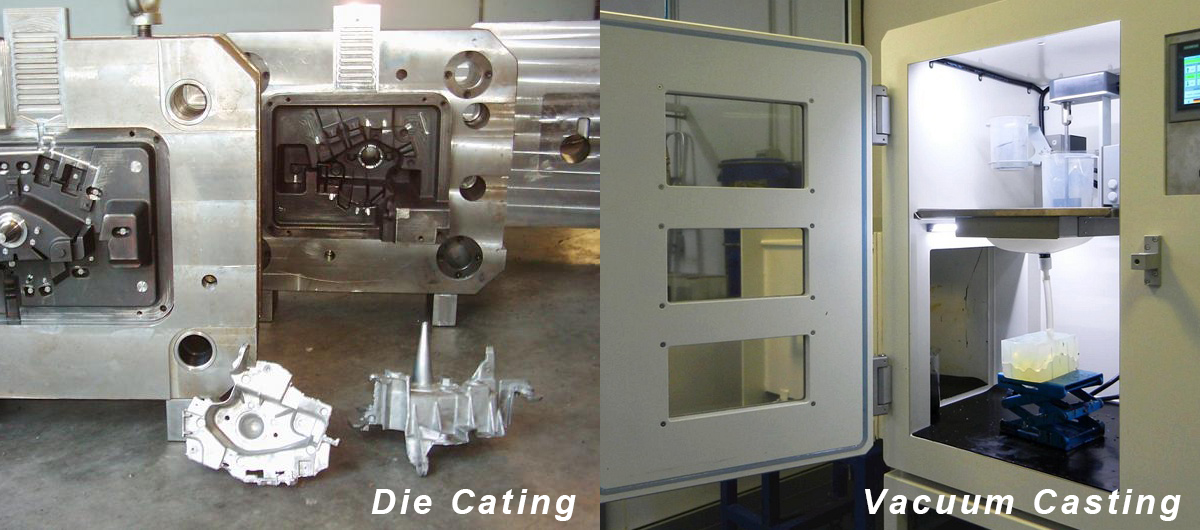

Exploring the Differences: Vacuum Casting vs. Die Casting

Die casting and vacuum casting are two methods commonly used in manufacturing. While both techniques involve the production of parts, there are distinct differences between the two.

In this guide, we'll explore the unique characteristics, advantages and disadvantages of die casting and vacuum casting to help you understand which method is best for your specific manufacturing needs.

Compare their differences:

Process | Die casting injects molten metal under high pressure into a reusable metal mold, also known as a die. The molten metal solidifies in the mold cavity and is then ejected as a solid part. | Vacuum casting, also known as silicone molding or polyurethane casting, the process creates a silicone based master pattern mold. A two-component liquid resin is then poured into the mold and vacuum pressure is applied to remove air bubbles and ensure detailed molding of the part. |

Materials | Die casting is primarily used for non-ferrous metals such as aluminum, zinc and magnesium alloys because of their low melting points and good castability. | Vacuum casting is compatible with a wide range of plastic materials, including polyurethane resins, silicone rubber and other low-temperature curing plastics. |

Complexity | Die casting is typically used to produce complex and delicate metal parts with high dimensional accuracy. The process is very suitable for parts with complex features and thin walls. | Vacuum casting can accurately reproduce intricate details and complex geometries, making it suitable for prototyping and low-volume production of parts with fine features. |

Production volume | Die casting is a high-volume production process that can produce large quantities of parts with consistent quality and short cycle times. | Vacuum casting is typically used for small-volume plastic part production, low-volume manufacturing and prototyping. It has the advantage of being able to produce small quantities of parts at low cost, without the need for expensive molds. |

Strength and Durability | Die castings typically exhibit excellent mechanical properties with high strength and durability. The process facilitates the production of strong and lightweight parts. | Vacuum cast parts exhibit good mechanical properties and can be designed to meet specific requirements. However, they may not be as strong as die-cast parts or parts produced through other metal forming processes. |

Surface finish | Due to high pressure injection and the use of metal molds, die castings usually have a smooth surface. | Vacuum cast parts can achieve a high quality surface finish, but the end result may depend on factors such as the quality of the mold and post-treatment techniques. |

Cost | Die casting molds are more expensive to produce than vacuum casting, which makes the process more suitable for high volume production. However, the cost per part decreases as the number of parts produced increases. | Vacuum casting molds are relatively inexpensive to produce compared to die casting molds. It is a cost effective option for small scale production and prototyping. |

Tooling | The production of die casting molds requires specialized tooling, which can increase lead times and initial costs. Modifications to the mold design can be more costly. | Vacuum casting molds are typically made of silicone rubber, which is relatively easy and fast to manufacture compared to the metal molds used in die casting. Modifying molds is usually simpler and more affordable. |

Applications | Die casting is commonly used in the automotive, aerospace and consumer electronics industries to produce metal parts such as engine parts, housings, brackets and structural parts. | Vacuum casting is widely used in industries such as product design, rapid prototyping and small batch production. It is more widely used to produce parts for prototypes, models, architectural models, medical devices, and consumer products. |

Tolerance Range | from ±0.05 mm to ±0.2 mm (±0.002" to ±0.008") | from ±0.1 mm to ±0.3 mm (±0.004" to ±0.012") |

Advantages of die casting:

The advantage of die casting is its ability to produce complex shapes with high precision and accuracy. Die casting also allows for the production of parts with thin walls and intricate details,

making it ideal for applications that require complex designs. In addition, die casting provides excellent dimensional stability, ensuring consistent and uniform parts.

The process is also very efficient, with high productivity and minimal material waste. It's offers a cost effective and reliable method for producing high quality metal parts.

Advantages of Vacuum Casting.

The advantage of vacuum casting is its ability to produce parts with high surface quality and detail. Vacuum casting allows the production of parts with smooth surfaces, fine detail and intricate textures,

making it ideal for applications that require aesthetic appeal. In addition, vacuum casting is a suitable method for producing small to medium sized parts with complex geometries.

It offers excellent dimensional accuracy and the ability to accurately reproduce complex features. Vacuum casting commonly the use of a wide range of plastics materials, including various types of resins and elastomers. It is offers a versatile and efficient method for producing high quality prototypes and small batches of plastic products.

Not sure which manufacturing method is better for your project?

→Let GD-HUB provide you with professional advice