——The past and future of additive manufacturing

Ⅰ:The Evolution of Additive Manufacturing: A Look Back in Time

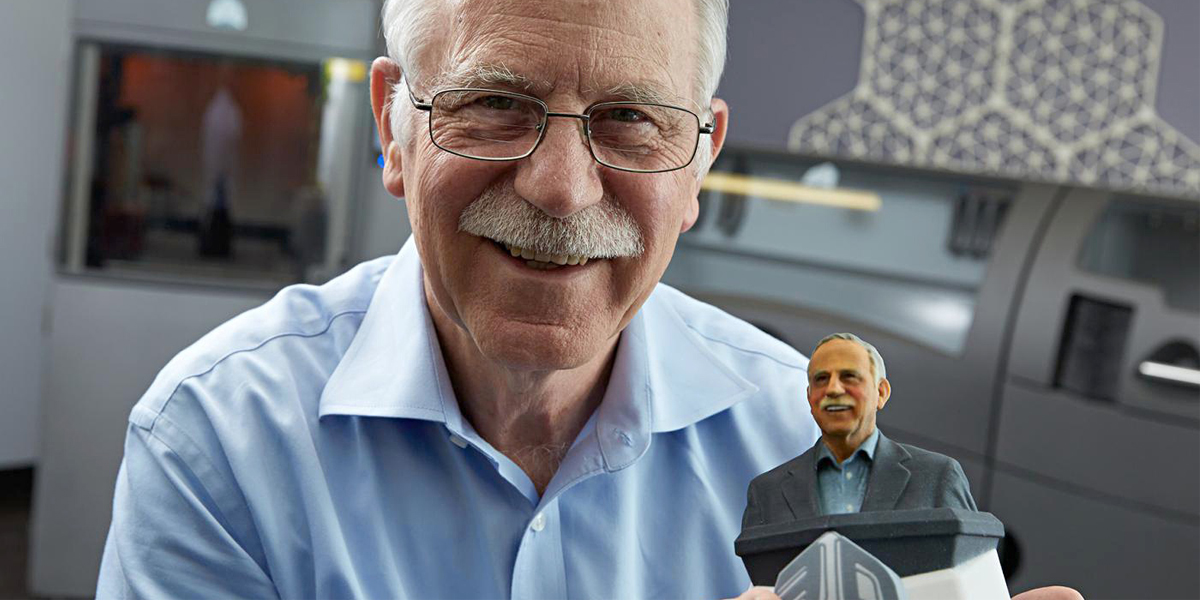

Origins: Additive manufacturing traces its roots back to the 1980s when the first 3D printing technologies were developed. The first 3D printer was created by Chuck Hull, who used a process called stereolithography to create a small plastic cup. However, it wasn't until the early 2000s that 3D printing became more widely available and affordable.These early systems used stereolithography, a process that solidified liquid resin using a laser, to create 3D objects layer by layer.

Limited Applications: Initially, additive manufacturing found use mainly in prototyping and rapid tooling applications. The technology was expensive, slow, and had limited material options, which restricted its broader adoption.

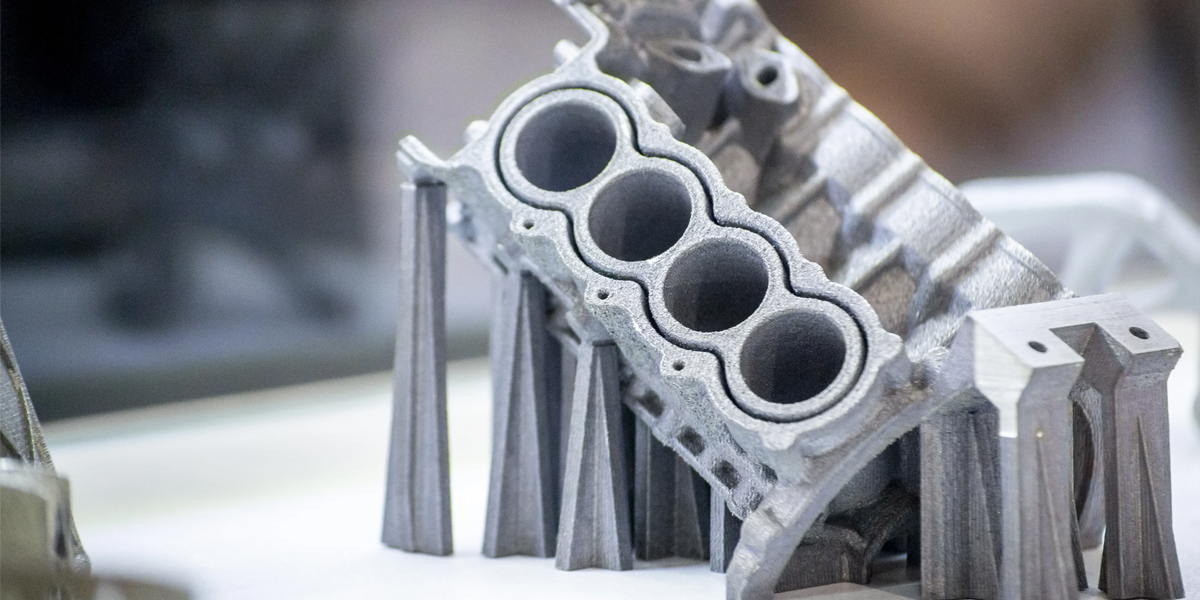

Industrial Applications: As the technology matured, additive manufacturing began to find applications in industries such as aerospace, automotive, and healthcare. The ability to produce complex geometries, reduce material waste, and create lightweight structures made it attractive for these sectors.

Ⅱ:The Present: Additive Manufacturing Today

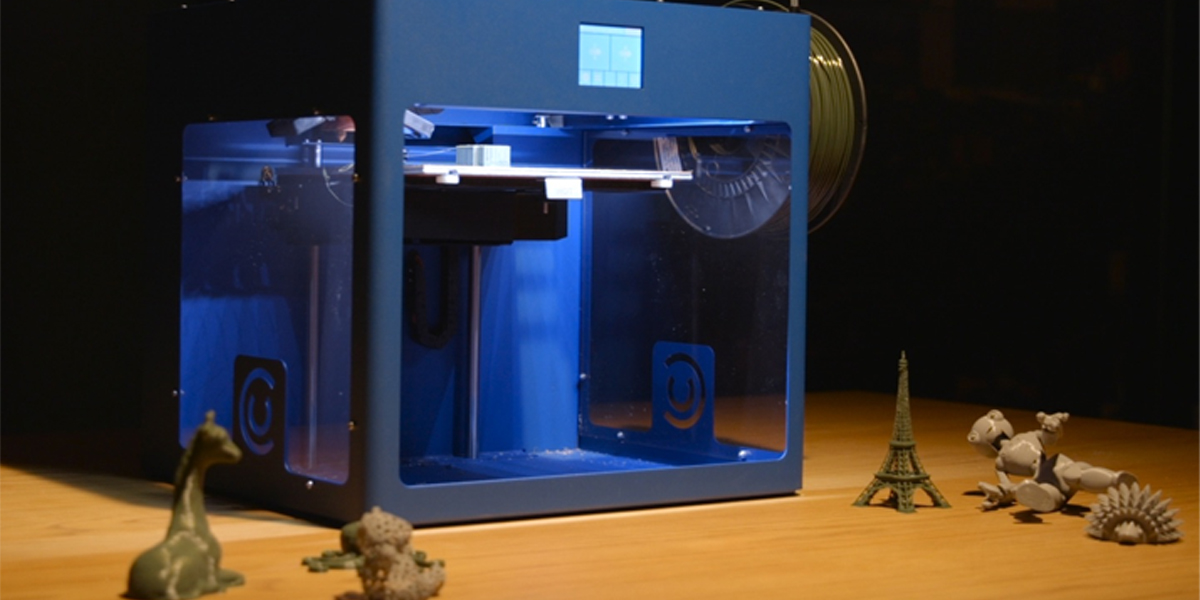

Today, additive manufacturing is used in a variety of industries, including aerospace, automotive, healthcare, and consumer goods. 3D printing has become more advanced, with the ability to print with a variety of materials, including metals, plastics, and even food. The technology has also become more accessible, with desktop 3D printers available for personal use.

Ⅲ: The Future: Advancements in Additive Manufacturing

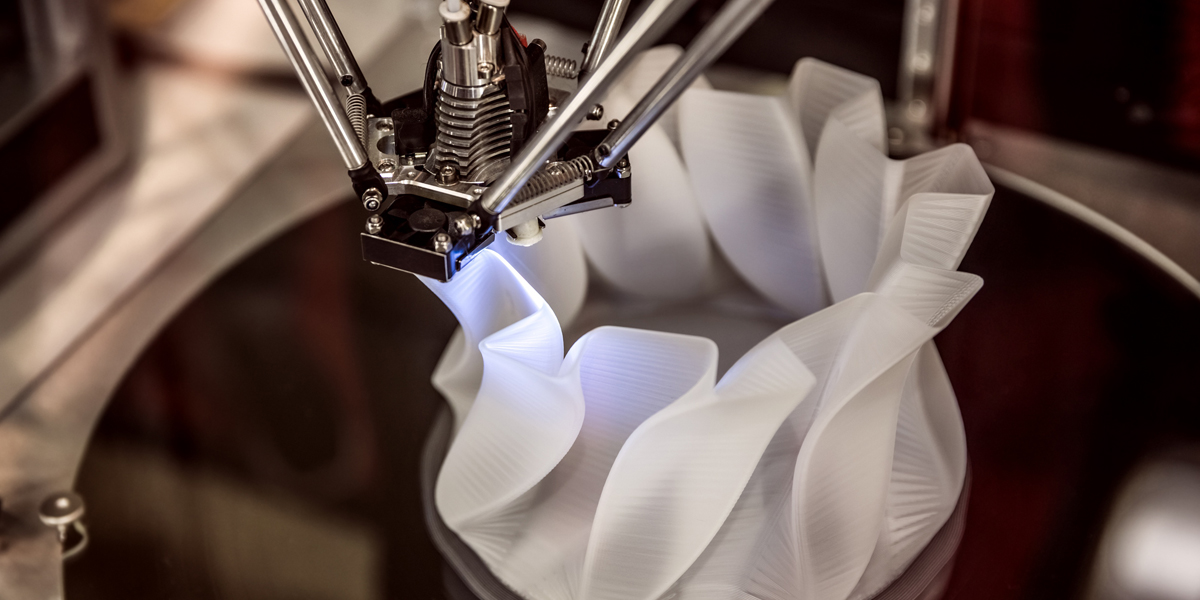

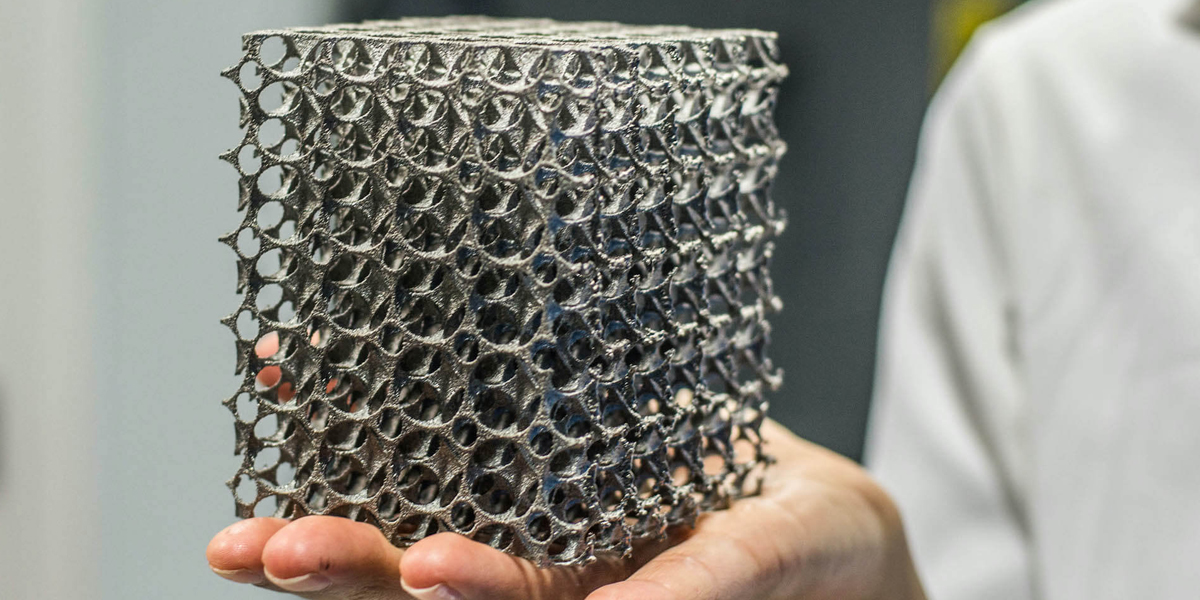

The future of additive manufacturing looks promising, with advancements in technology and materials. One area of focus is on bioprinting, which involves printing living tissue and organs for medical purposes. Another area of focus is on printing with sustainable materials, such as recycled plastics and biodegradable materials. Additionally, 3D printing is being used to create complex geometries and structures that would be difficult or impossible to create with traditional manufacturing methods.

Advanced Materials: The development of new materials will continue to expand the possibilities of additive manufacturing. This includes high-performance metals, multi-material printing, conductive inks, biocompatible materials, and more.

Improved Speed and Scale: Ongoing research aims to enhance printing speeds while maintaining accuracy and quality. Scaling up the production capabilities of additive manufacturing will enable more widespread adoption in high-volume manufacturing.

Digital Workflow Integration: Additive manufacturing is becoming an integral part of digital manufacturing workflows. Seamless integration with computer-aided design (CAD), simulation, and automation systems will optimize the entire manufacturing process.

Additive Manufacturing and Sustainability:As the world becomes more focused on sustainability, additive manufacturing is expected to play a role in reducing waste and carbon emissions. 3D printing allows for on-demand production, reducing the need for large-scale manufacturing and transportation. Additionally, the ability to print with sustainable materials and recycle waste materials could further reduce the environmental impact of manufacturing.

Multi-Domain Applications: Additive manufacturing will find applications across a broad range of industries, including construction, electronics, fashion, and food. Customized building components, printed electronics, personalized apparel, and 3D-printed food are just a few examples of future possibilities.

Challenges and limitations of 3D printing technology:

While 3D printing has many potential benefits, there are also some challenges and limitations to the technology. One of the main limitations is the size of the objects that can be printed. Most 3D printers have a limited build volume, which means that larger objects may need to be printed in multiple pieces and then assembled. Additionally, the quality of the printed objects can be affected by factors such as the type of material used and the printing process itself. Finally, there are still some technical and regulatory challenges that need to be addressed before 3D printing can be widely adopted in certain industries, such as healthcare and aerospace.

——How is 3D printing being used in our lives?

1.Medical Applications

3D printing has revolutionized the medical industry. It is used to create patient-specific models for surgical planning, customized implants, prosthetics, and anatomical models for medical education. Additionally, bioprinting techniques are being explored to print living tissues and organs for transplantation and regenerative medicine.

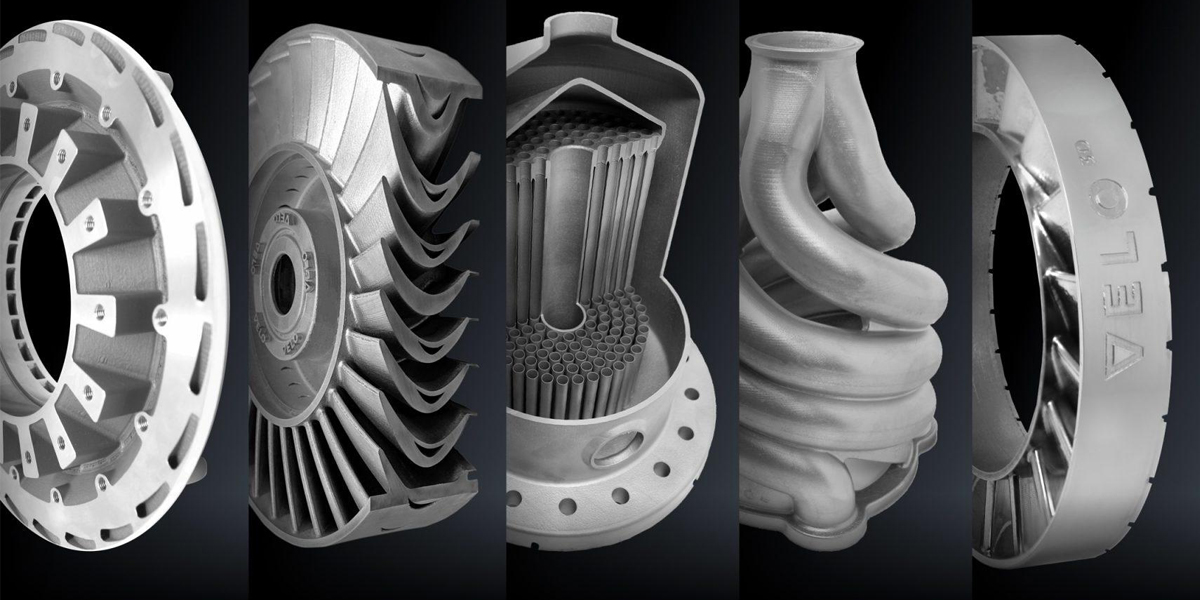

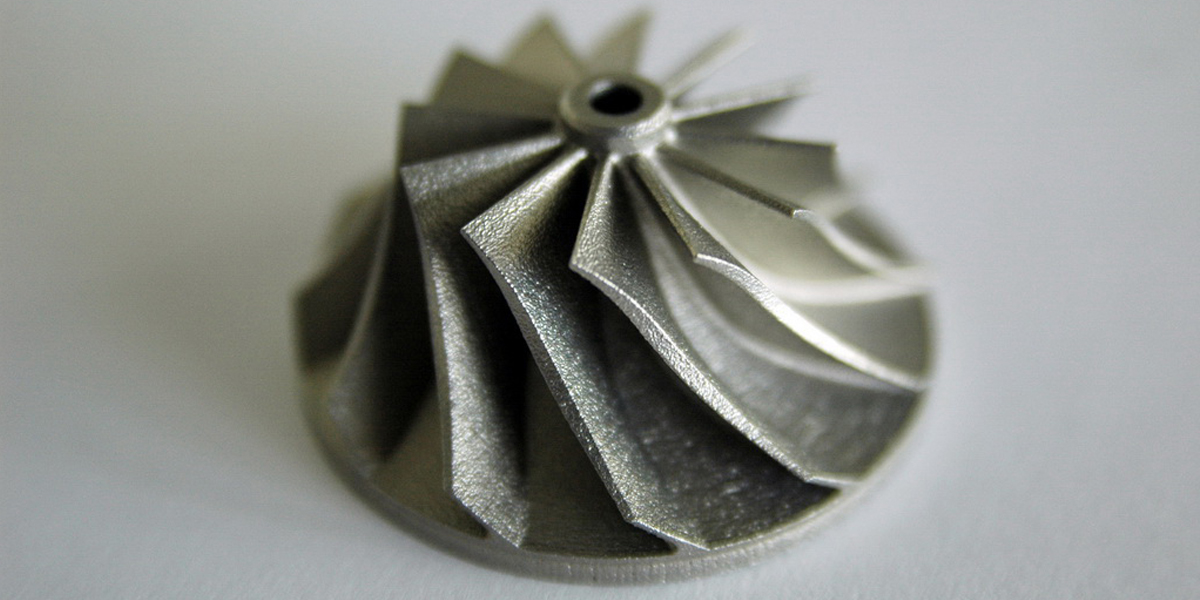

2. Aerospace Industry

The aerospace industry has been using 3D printing to create rapid prototyping, lightweight component manufacturing, and complex part production. It enables the creation of intricate designs, reduces weight, and enhances performance, making it an ideal technology for these sectors. for faster production times and reduced costs.

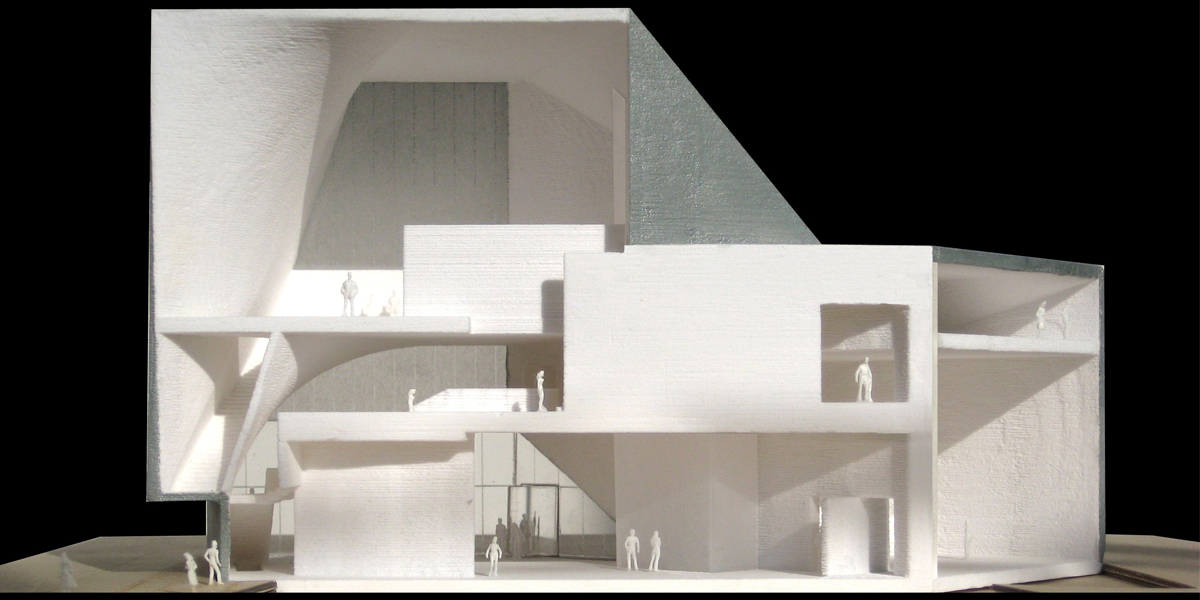

3. Architecture and Construction

3D printing has been used in architecture and construction to create intricate and complex designs that would be difficult to achieve with traditional methods. This technology has also been used to create models of buildings for pre-construction planning.

4. Automotive Industry

The automotive industry has been using 3D printing to create prototypes and parts for cars. This technology has allowed for faster production times and reduced costs.

5. Education

3D printing has been used in education to teach students about design, engineering, and manufacturing. This technology has allowed for hands-on learning experiences and has sparked creativity in students. From primary schools to universities.,it is used to enhance STEM education by enabling students to design and fabricate their own objects. Researchers also use 3D printing to create prototypes, experimental models, and intricate structures for various scientific studies.

6. Designer Industry

Artists, designers, and fashion designers are leveraging 3D printing to push the boundaries of creativity. It allows for the production of intricate sculptures, jewelry, and unique fashion pieces that were previously challenging to manufacture using traditional methods.This technology has allowed for more sustainable and eco-friendly production methods.

7. Food Industry

3D printing has been used in the food industry to create customized and intricate designs for desserts and other food items. This technology has allowed for more creative and visually appealing dishes.

8. Consumer Products and Customization:

3D printing is increasingly being adopted by companies to offer customizable products to consumers. From personalized smartphone cases to custom-made shoes, 3D printing enables mass customization, where individual customers can have unique products tailored to their preferences.

9. Prototyping and Product Development:

3D printing is extensively used in product development to create prototypes. It enables designers and engineers to quickly iterate and test their designs, reducing time and cost compared to traditional prototyping methods.

And also additive manufacturing is increasingly being used for manufacturing end-use parts and components. It allows for the production of complex geometries, customized designs, and small-batch or on-demand manufacturing.

Before your 3d printing project starts, choosing a trustworthy manufacturer is key to ensuring a successful project. That's where GD-HUB's 3D printing services come in.

We offer comprehensive support throughout the entire process, from design to delivery. Our team is always available to provide guidance and assistance, ensuring that your project runs smoothly and meets your expectations.

With a strong reputation in the industry and a track record of delivering high-quality products and exceptional customer service, you can trust GD-HUB for all your 3D printing needs.