What is Extrusion?

Extrusion is a versatile and efficient manufacturing process that offers numerous benefits in the production of continuous profiles. Its ability to shape materials into complex geometries, maintain consistency and precision, and its cost-effectiveness make it a valuable technique in various industries. Whether used for metals, plastics, or other materials, extrusion plays a crucial role in creating a wide range of products that meet diverse application requirements.

In this article, GD-UHB will explore the fundamentals of extrusion, its working principle, and its advantages in the manufacturing process with you.

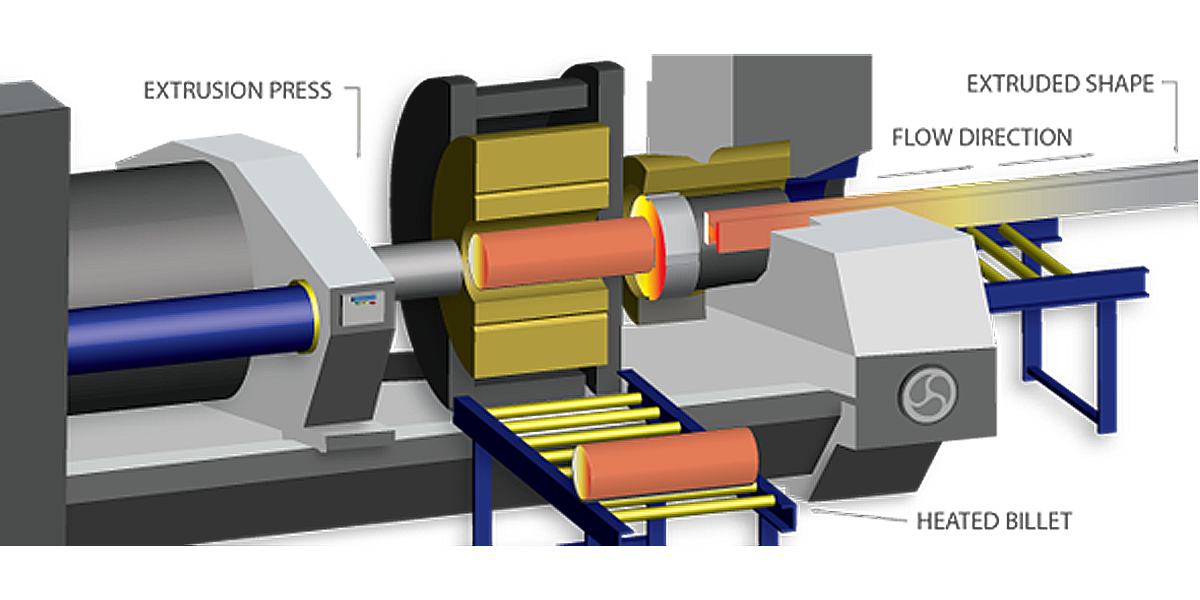

Working Principle of Extrusion

The extrusion process relies on the principle of plastic deformation, where the material is softened or melted to allow it to flow and take on the shape of the die. The key components of an extrusion system include an extruder, a die, and a downstream cooling and sizing apparatus.

The extruder consists of a screw or a ram that feeds the material into a heated barrel. As the material progresses through the barrel, it is heated and mixed to achieve uniform consistency and temperature. The molten material is then forced through the die, which has a specific cross-sectional shape, such as a tube, rod, or profile.

Extrusion's Advantages

Extrusion offers several advantages that make it a preferred manufacturing process in many industries:

Versatility: Extrusion can be used with a wide range of materials, including metals (such as aluminum, copper, and steel), plastics, rubber, and even food products. This versatility allows for the production of diverse products with different physical properties.

Cost-effectiveness: Extrusion is a cost-effective process, especially for high-volume production. It allows for continuous production of long profiles, reducing the need for additional processing steps and minimizing material waste.

Consistency and Precision: The use of dies in extrusion ensures consistent and precise dimensions and shapes of the extruded products. This makes extrusion suitable for applications that require tight tolerances and uniformity.

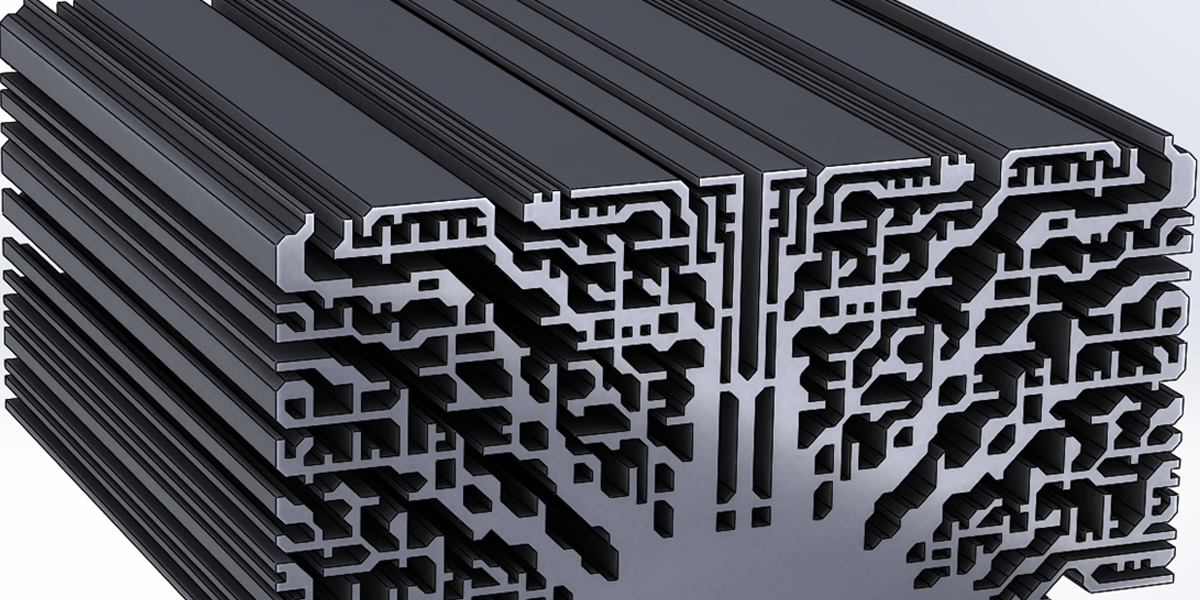

Complex Geometries: Extrusion can produce products with complex cross-sectional profiles that are difficult or impossible to achieve with other manufacturing processes. The flexibility of the die design allows for the creation of intricate shapes and features.

Strength and Structural Integrity: Extruded products often exhibit improved strength and structural integrity due to the alignment of the material's molecular structure during the extrusion process. This makes extrusion ideal for applications requiring high strength and durability.

Common Types of Extrusion Processes

There are different types of extrusion processes, each suited for specific materials and applications:

Hot Extrusion: Hot extrusion is primarily used for metals. The material is heated to a temperature above its recrystallization temperature, making it more malleable and easier to extrude.

Cold Extrusion: Cold extrusion is commonly used for materials that do not require high temperatures, such as certain metals and thermoplastics. The material is forced through the die at room temperature or slightly elevated temperatures.

Direct Extrusion: In direct extrusion, the material is placed in a chamber, and a ram pushes it through the die in a single continuous motion.

Indirect Extrusion: Indirect extrusion involves a stationary die and a moving mandrel or punch that pushes the material through the die. This process allows for more complex shapes and better control over wall thickness.

Coextrusion: Coextrusion involves extruding multiple materials simultaneously through multiple dies to create composite products with different layers or properties. This process is commonly used in the production of multi-layered plastic films and profiles.

Materials available for extrusion

Extrusion is a widely used manufacturing process that can be applied to various materials, each with its own unique properties and applications.

Metals: Metal extrusion involves the shaping of metals such as aluminum, copper, steel, and their alloys. It is commonly used to produce profiles, tubes, rods, and other components for industries like construction, automotive, aerospace, and electrical.

Plastics:Extrusion is extensively used for thermoplastics, which can be melted and reshaped repeatedly. Some commonly extruded thermoplastics include polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), and acrylonitrile butadiene styrene (ABS). Plastic extrusion finds applications in packaging, construction, automotive, and consumer goods industries.

Rubber: Rubber extrusion involves materials like natural rubber, synthetic rubber (such as styrene-butadiene rubber or SBR), silicone rubber, and ethylene propylene diene monomer (EPDM). Rubber extrusion is used to create seals, gaskets, tubing, and various other rubber products in industries like automotive, construction, and manufacturing.

Ceramic: Ceramic extrusion is used to shape clay-based materials into consistent and intricate forms. It is commonly employed in the production of ceramic tiles, bricks, pipes, and other ceramic components.

Composite Materials: Extrusion can also be applied to composite materials, which combine different substances to create unique properties. Examples include extruding plastic composites with reinforced fibers (such as fiberglass or carbon fiber) for applications in aerospace, automotive, and construction industries.

Filaments: In the field of 3D printing, plastic filaments are extruded to create precise layers and build three-dimensional objects. Materials commonly used for 3D printing filaments include polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), polyethylene terephthalate (PET), and others.

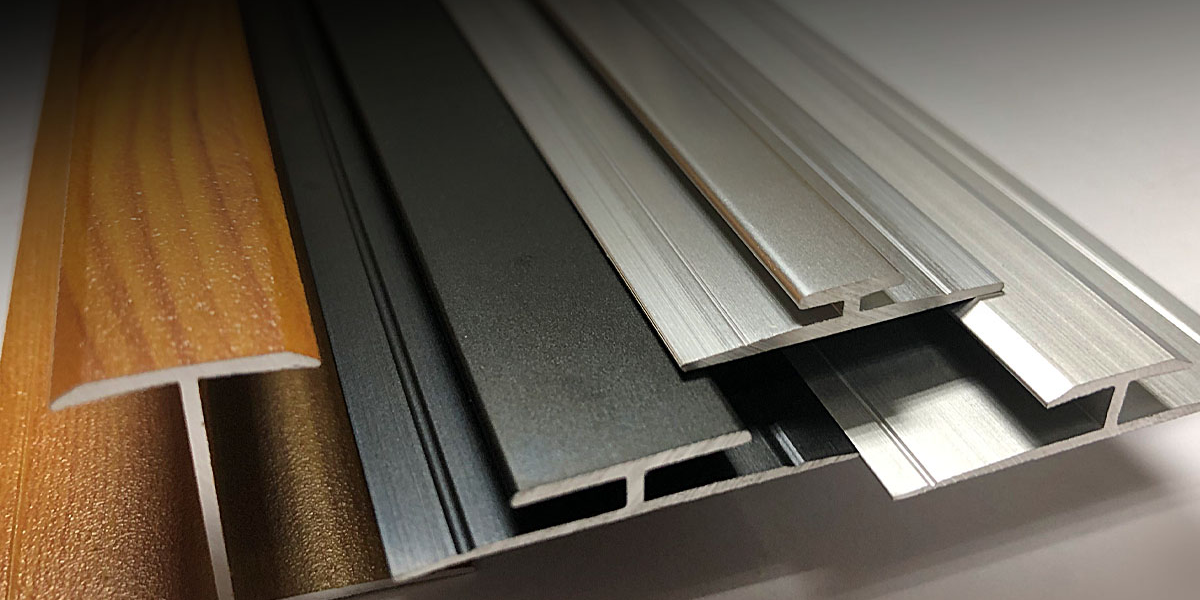

Surface Finishing Selection for Extrusion

When it comes to surface finishing for extruded products, there are several options available to enhance their appearance, functionality, and durability. The choice of surface finishing technique depends on the material being extruded, the desired final appearance, and the intended application of the product.

Anodizing: Anodizing is a popular surface treatment for aluminum extrusions. It involves creating an oxide layer on the surface of the aluminum through an electrochemical process. Anodizing provides corrosion resistance, improves surface hardness, and allows for coloring options.

Powder Coating: Powder coating is a process where a dry powder is applied electrostatically to the surface of the extrusion and then cured under heat to create a durable, smooth, and decorative coating. Powder coating offers a wide range of color choices, excellent corrosion resistance, and can provide additional protection to the extruded product.

Painting: Painting is a versatile surface finishing technique that allows for customization and a wide range of color options. It can be used on various materials, including metals and plastics. Primers, paints, and clear coats are applied to the surface to provide the desired appearance and protection.

Plating: Plating involves depositing a layer of metal, such as chrome, nickel, or zinc, onto the surface of the extruded product. Plating can improve corrosion resistance, provide a decorative finish, and enhance the conductivity of the material. It is commonly used for metal extrusions.

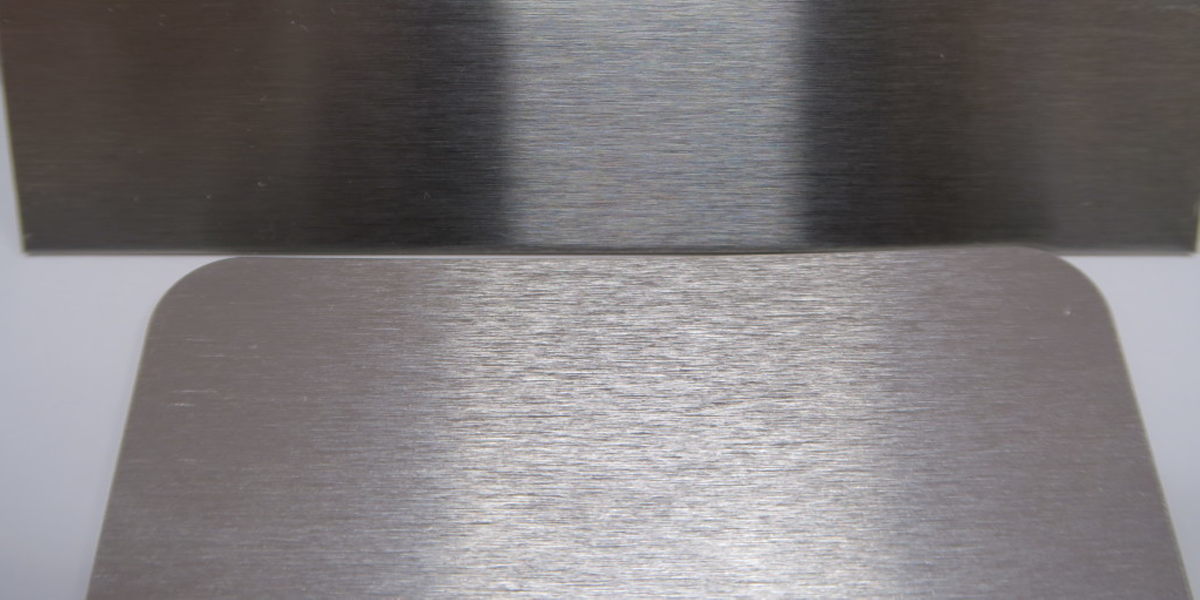

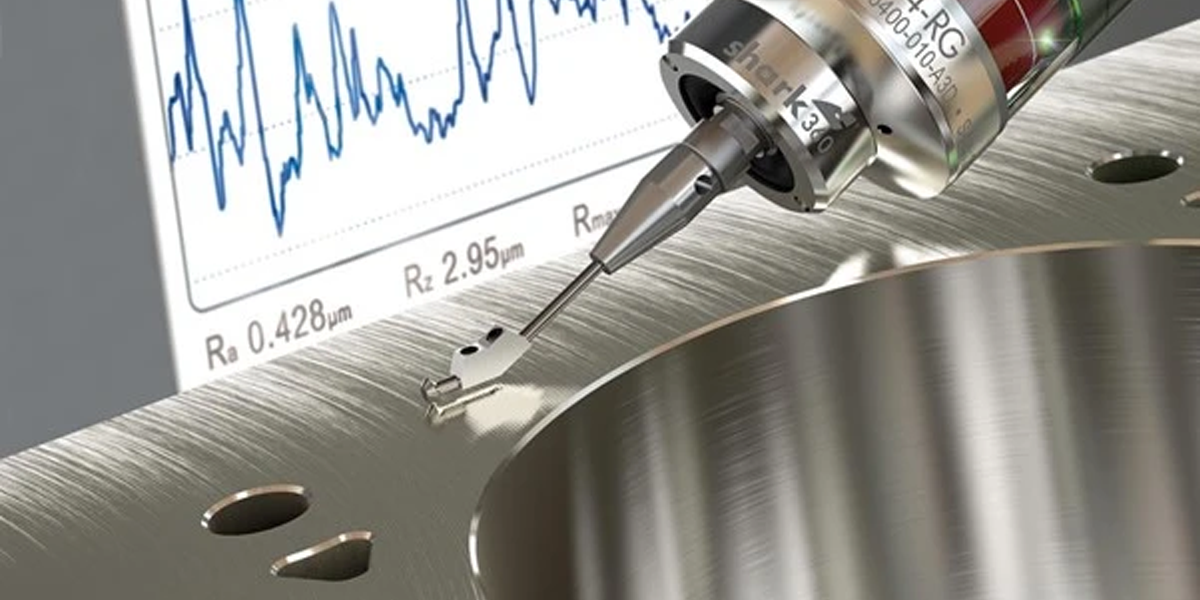

Brushing/Polishing: Brushing or polishing the extruded surface can create a smooth, reflective finish. This technique is often used for aluminum and stainless steel extrusions to achieve a polished or satin appearance.

Etching/Engraving: Etching or engraving can be used to create patterns, logos, or text on the surface of the extrusion. This technique is commonly employed for branding or decorative purposes.

Anodized Printing: Anodized printing is a specialized technique where a design or pattern is printed onto the anodized surface of the extrusion. This method allows for customization and branding while retaining the benefits of anodizing.

Texturing: Texturing techniques can be applied to create unique surface patterns or textures on the extrusion. This can include embossing, stippling, or other surface treatments that enhance the grip, aesthetics, or functionality of the product.

The selection of surface finishing technique will depend on factors such as the material, aesthetic requirements, corrosion resistance, functional properties, and budget considerations. It's important to consult with GD-HUB'S experts or surface finishing specialists to determine the most suitable technique for your specific extrusion application.

Design Considerations You Need To Attention About Extrusion

When designing for extrusion, there are several important considerations to take into account to ensure a successful and efficient extrusion process.

Material Selection: Choose a material that is suitable for extrusion and meets the requirements of your application. Different materials have different extrusion characteristics, such as melt flow properties and temperature sensitivity. Consider factors such as strength, flexibility, heat resistance, and desired surface finish when selecting a material.

Wall Thickness: Maintain consistent wall thickness throughout the extrusion profile to ensure uniformity and structural integrity. Avoid abrupt changes in thickness, as this can lead to uneven cooling and potential defects. Thin walls can be more prone to distortion or warping during the extrusion process, so appropriate thickness should be chosen based on material properties and design requirements.

Cross-Sectional Shape: The cross-sectional shape of the extrusion profile will determine its functionality, strength, and ease of extrusion. Common shapes include solid bars, tubes, channels, and complex geometries. Consider the intended use of the extruded product and select a shape that optimizes its performance and manufacturability.

Draft Angles: Incorporate draft angles into the design to facilitate the smooth removal of the extruded profile from the die. Draft angles help prevent sticking or binding and minimize the force required for extrusion. Typically, a draft angle of 1-3 degrees is recommended.

Fillets and Radii: Incorporate fillets or radii in sharp corners or transitions to reduce stress concentration and improve the flow of the material during extrusion. Smooth transitions help maintain structural integrity and improve the overall appearance of the extruded profile.

Support Structures: Consider the need for support structures or webs within the extrusion to enhance rigidity and prevent distortion. These supports can be designed as integral parts of the profile or added during post-extrusion processes.

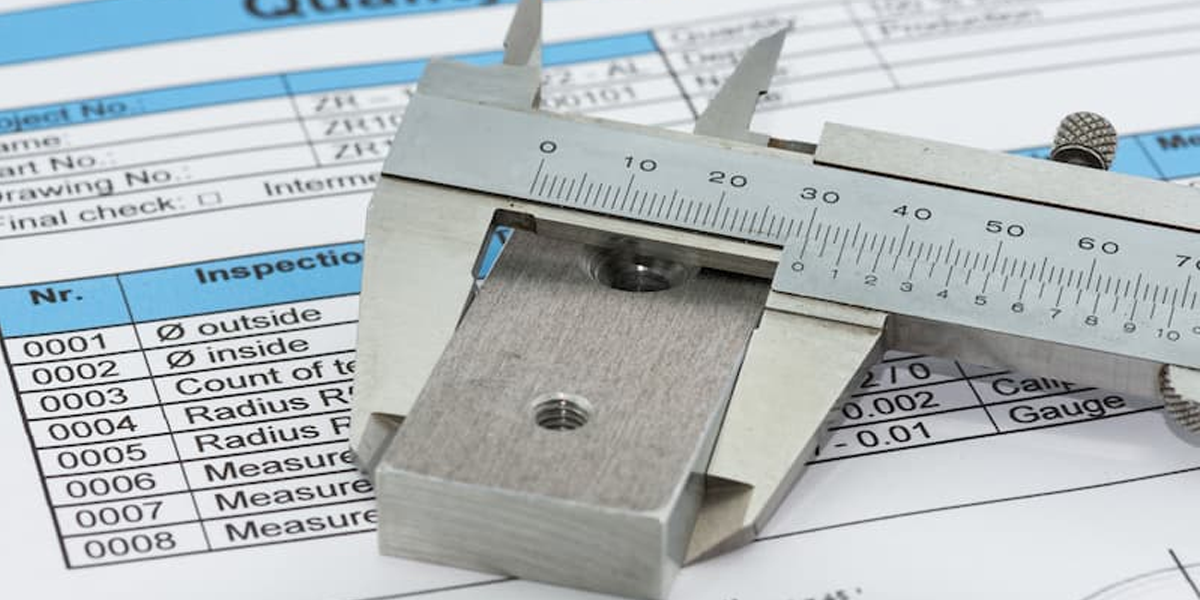

Tolerances: Define appropriate tolerances for critical dimensions to ensure the extruded product meets the desired specifications. Consult with the extrusion manufacturer to understand the achievable tolerances based on the material and extrusion process.

Surface Finish: Consider the desired surface finish and any additional surface treatment processes that may be required after extrusion, such as anodizing, painting, or coating. Design features should accommodate these surface finishing requirements.

Machining and Assembly: If post-extrusion machining or assembly is required, ensure that the design allows for these processes. Consider factors such as hole placements, dimensional requirements, and accessibility for machining or joining methods.

Cost and Efficiency: Design with cost and efficiency in mind. Minimize material waste by optimizing the extrusion profile layout and considering nesting of multiple profiles. Avoid complex and intricate designs that can increase manufacturing complexity and costs.

It is important to work closely with an experienced extrusion manufacturer or engineer during the design phase to ensure that your design meets the capabilities and limitations of the extrusion process. Their expertise can help optimize your design for successful extrusion and ensure the production of high-quality extruded products.

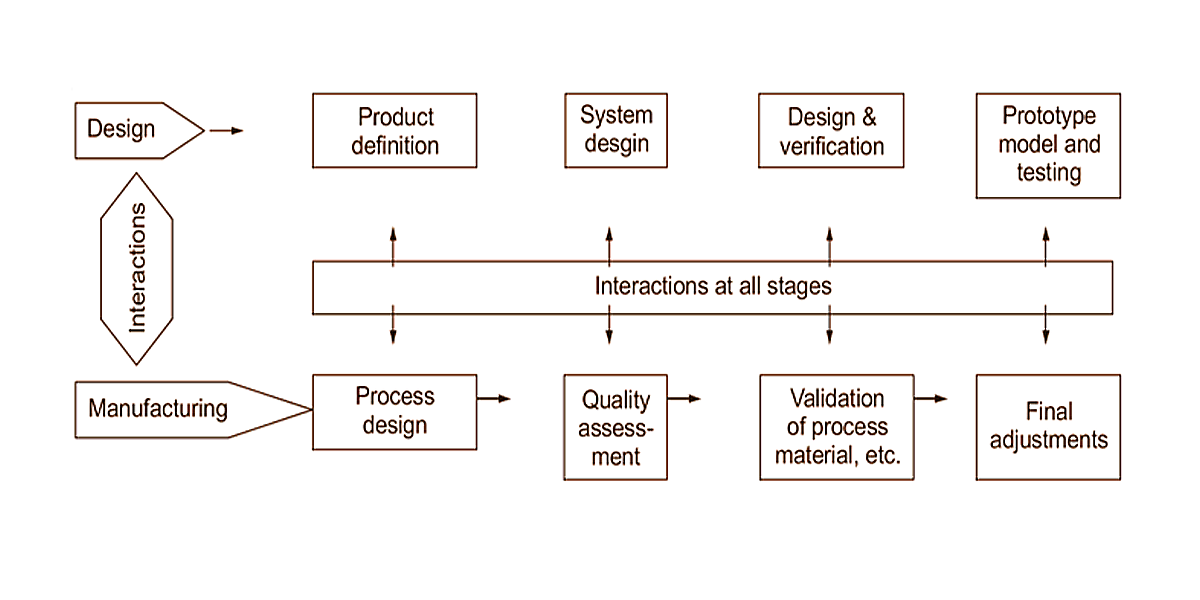

Helpful DfM Tips for Extrusion

Design for Manufacturing (DfM) is a crucial aspect when designing for extrusion.

Keep Designs Simple: Simplify the design as much as possible to minimize complexity and optimize manufacturability. Avoid unnecessary features, intricate geometries, and excessive detailing that can increase production costs and potential defects.

Use Standard Profiles: Whenever feasible, utilize standard extrusion profiles that are readily available. Standard profiles are more cost-effective and can be produced in larger quantities, resulting in shorter lead times and lower production costs.

Maintain Symmetry: Symmetrical designs are easier to extrude and ensure consistent material flow. Symmetry helps maintain balanced cooling and reduces the risk of distortion or warping during extrusion.

Avoid Undercuts and Overhangs: Undercuts and significant overhangs can make extrusion more challenging. These features may require additional tooling or post-extrusion machining, increasing costs and complexity. Minimize undercuts and overhangs wherever possible.

Consider Draft Angles: Incorporate draft angles into the design to facilitate the smooth removal of the extruded profile from the die. Adequate draft angles reduce friction and sticking, resulting in improved extrusion efficiency.

Design for Minimum Wall Thickness: Design profiles with consistent and minimal wall thickness to ensure uniform cooling and material flow. Thick sections take longer to cool, leading to potential defects, while excessively thin sections may cause instability during extrusion.

Fillets and Radii: Include fillets or radii in corners and transitions to reduce stress concentrations and improve material flow. Smooth transitions enhance extrusion efficiency and help maintain structural integrity.

Avoid Sharp Corners: Sharp corners can lead to stress concentrations and potential material flow issues during extrusion. Round or chamfer the corners to distribute stress and facilitate material flow.

Tolerance Considerations: Define appropriate tolerances for critical dimensions based on the extrusion process capabilities and material properties. Consult with the extrusion manufacturer to understand the achievable tolerances and ensure that they align with your design requirements.

Consider Post-Extrusion Operations: Anticipate any post-extrusion operations such as machining, assembly, or surface finishing. Design features and tolerances should accommodate these processes without compromising the functionality or integrity of the extruded product.

Material Selection: Choose materials that are suitable for extrusion and readily available. Consider the material's melt flow properties, temperature sensitivity, and desired mechanical properties to ensure successful extrusion.

Communicate with the Extrusion Manufacturer: Collaborate closely with the extrusion manufacturer or engineer throughout the design process. Their expertise and feedback can help optimize your design for efficient extrusion and avoid potential issues or limitations.

By following these DfM tips, you can enhance the manufacturability of your extruded products, improve production efficiency, and reduce costs. Collaboration with GD-HUB experienced extrusion services is highly recommended to leverage our expertise and ensure your successful extrusion project.