9001:2005

CERTIFICATED

CNC

MACHINES 100+

CNC PARTS

MADE MONTHLY 16K+

MATERIALS

PLASTIC & METAL 100+

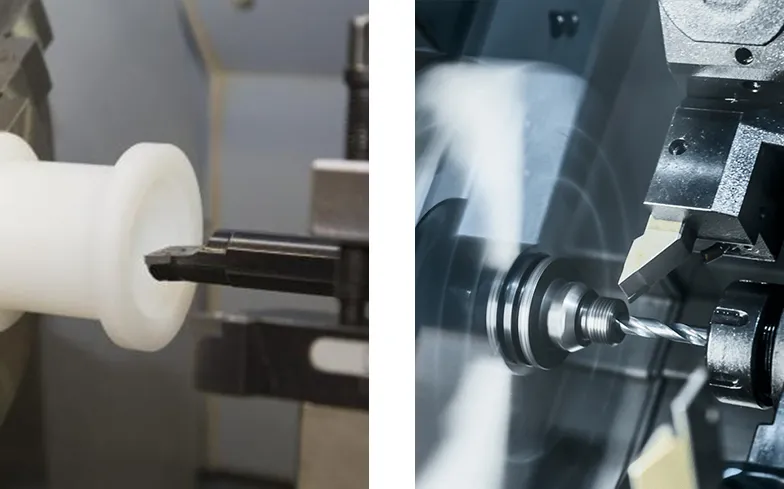

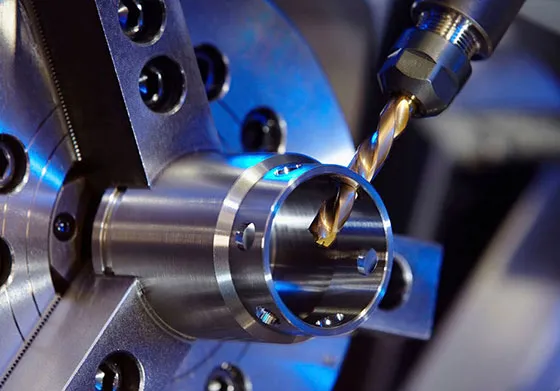

CNC turning (CNC Lathing) is an efficient and precise machining method for a wide range of materials including metals, plastics and composite material. GD HUB uses state-of-the-art CNC machining centres to machine aluminium, stainless steel, titanium, standard alloys, super alloys and more. With multi-axis capabilities, live tooling and quick-change fixtures, our turning machines achieve consistent results from precise machining to repeat production on parts and assemblies with tight tolerances.CNC turning is widely used in:1. Aerospace;2. Automotive manufacturing;3. Medical devices;4. Electronic products;5. Machinery Manufacturing.

Why Choose Us:

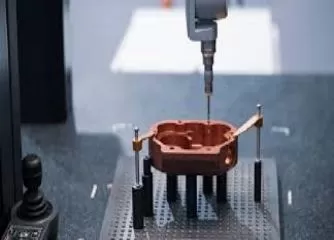

GD-HUB offers a full range of CNC lathe machining services, including prototyping and full production. With state-of-the-art turning equipment and a manufacturing team with 20 years of experience, we are able to produce high precision, high quality parts that meet the most stringent requirements. We offer tolerance options to ISO 2768 (Standard, Fine) and ISO 286 (Grades 8, 7, 6) and are ISO 9001 certified. We integrate our CNC turning and milling centers with our CMM and Quality Assurance departments to ensure the accuracy and quality of finished parts. The Quality Assurance Center uses CMMs for in-process and final production inspections to ensure our customers get the best prototypes possible.

ISO certified

ISO certified

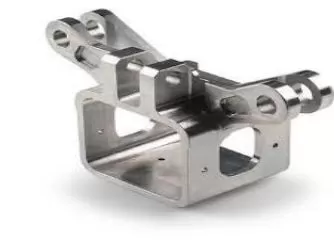

Turned Parts with Tight Tolerances

Turned Parts with Tight Tolerances

(Tolerances up to ±0.0004″ (0.01mm)

Fast Lead Time 3-15 days

Fast Lead Time 3-15 days

24H/7d Engineering Support

24H/7d Engineering Support

Capabilities Of GD-HUB CNC Turning Service

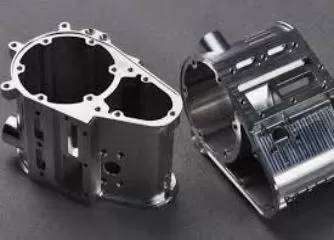

GD-HUB's precision CNC turning service is equipped with over 80 advanced and professional machines, including CNC milling and swiss turning. This allows for precise, efficient, flexible, and automated production with high repeatability, minimal waste, and reduced labor costs. It is a cost-effective and reliable manufacturing process that is ideal for mass production of complex parts. With GD-HUB's CNC turning services, you can expect excellent capabilities and top-notch results.

High Precision

GD-HUB's CNC turning machines are capable of producing precision parts with tight tolerances and high accuracy. We work with metal bar stock up to 1.25” O.D. and can machine faces and flats with tolerances of up to ±0.0005”, and feature positions and profiles at up to ±0.0005”.

Best Efficiency

GD-HUB's CNC turning is far ahead of the industry, our CNC turning machines can produce parts faster than traditional one, with experienced team for CNC Turning who use computer-controlled cutting tools to perform multiple operations at once. This can save a lot of time and costs in the production process.

Operation Flexibility

GD-HUB's experienced team of CNC turning can be programmed to produce a wide variety of parts with different sizes, shapes, and materials. This means that we can quickly adapt to changing customer demands and produce parts in small or large quantities as needed.

Processable Materials

GD-HUB provides highly precise CNC turning services and swiss turning services to a variety of businesses for a wide range of material machining needs, including metals such as steel, aluminum, brass, copper, titanium and magnesium, as well as plastics, ceramics and more. We offer more than 100 production-grade materials to choose from to ensure the best solution for your project requirements. If you have other unknown special needs or questions, please contact us for personalized assistance.