9001:2005

CERTIFICATED

CNC

MACHINES 100+

CNC PARTS

MADE MONTHLY 16K+

MATERIALS

PLASTIC & METAL 100+

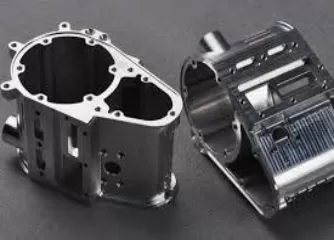

CNC milling is a highly precise manufacturing process that use of a computer-controlled machine to remove material from a workpiece. Guided by a computer program that specifies the exact movements and amount of material to be removed. CNC milling process is ideal for creating complex shapes and designs with a high degree of accuracy. Precision CNC milling is widely used in industries such as aerospace, automotive, and medical device manufacturing, where precision and consistency are critical. With CNC milling Services, manufacturers can produce high-quality parts and components with minimal waste and maximum efficiency.

Why Choose Us:

GD-HUB offer a comprehensive range of CNC milling services to meet all your manufacturing needs. Our state-of-the-art equipment includes 3 axis CNC Mill, 4 axis, and full 5-axis milling machines, operated by a team of experienced professionals who are committed to delivering the highest quality results. Whether prototyping or full production runs, we have the capabilities to produce accurate and precise parts that meet even the most stringent requirements. In addition, our CNC machining services perfectly complement our 3D printing service, making us your one-stop-shop for all your advanced design needs.

ISO certified

ISO certified

Milled Parts with Tight Tolerances

Milled Parts with Tight Tolerances

(Tolerances up to ±0.0004″ (0.01mm)

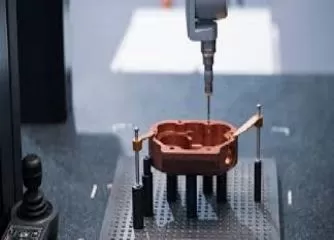

Leading quality inspection and testing

Leading quality inspection and testing

Quick delivery 3-7 days

Quick delivery 3-7 days

24H/7d Engineering Support

24H/7d Engineering Support

Get Your CNC Milling Parts in Just a Few Steps

Our CNC milling services are equipped with over 80 advanced and professional machines, allowing us to offer precise, efficient, and flexible production with high repeatability and minimal waste. Automated process also reduces labor costs, making it a cost-effective and reliable option for mass production of complex parts. Our CNC milling services provide excellent manufacturing capabilities such as precision cutting, multi-axis machining, and the ability to work with a variety of materials including metals, plastics, and composites.

1. Upload your design files

Send your part design file in any format to the GD-HUB team and our team will reply to your message within 1 hour to generate a quote.And GD-HUB will provide you with a DFM analysis report to verify the feasibility of the design.You also have the option of signing a non-disclosure agreement to protect your parts.

2. Choosing the best match solutions

Through the DFM report, GD-HUB can assist customers to find out the problems of design, appearance, function, processing, etc., and through evaluation and improvement, select the best processing technology and material, reduce the time of repeated trial production verification, save the cost of manpower and materials, improve the quality of product production, and accelerate the speed of mass production.

3. Determine your order and waiting

After completing all the solutions, all you need to do is to confirm the order and pre-pay in a secure environment and then the short wait begins. Your design will be manufactured by experienced engineers. In a very short time, GD-HUB will finalize the parts with you and deliver your parts safely to your delivery address. You can track your package at any time.

Processable Materials

Our CNC milling services have the capability to work with a diverse range of materials, including metals like steel, aluminum, brass, copper, titanium, and magnesium, as well as plastics, ceramics, and more. We offer a comprehensive list of over 100 production grade materials to choose from, that you can find the perfect fit for your project. If you have specific requirements or questions, don't hesitate to reach out to us for personalized assistance.