9001:2005

CERTIFICATED

CNC

MACHINES 100+

CNC PARTS

MADE MONTHLY 16K+

MATERIALS

PLASTIC & METAL 100+

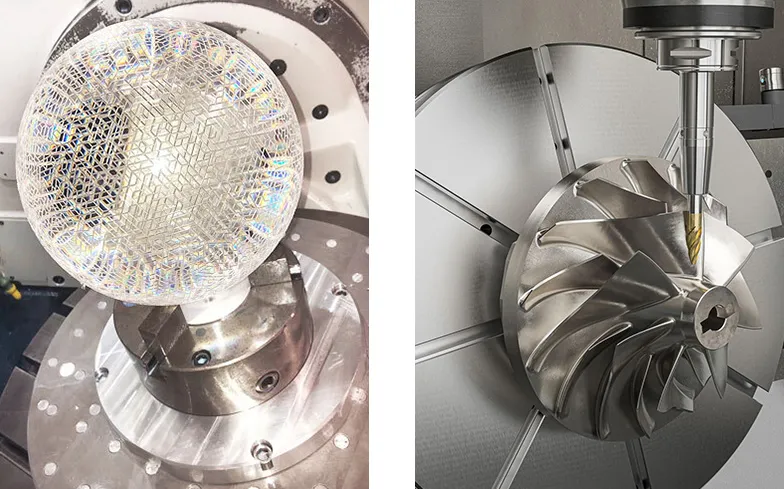

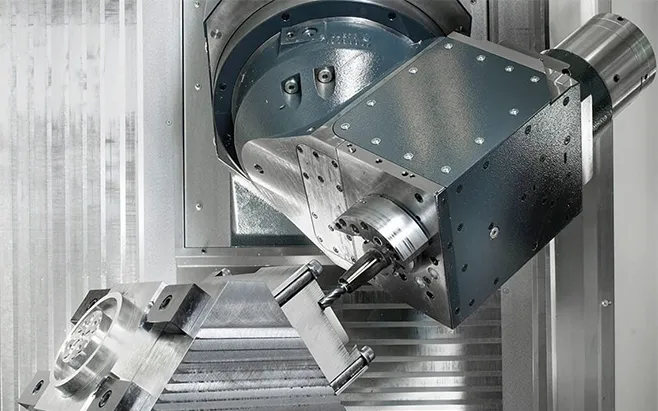

5-axis CNC machining is an advanced precision machining technology that uses Computer Numerical Control (CNC) technology to control the movement of the machine tool and cutter in five different axes.In 5-axis CNC machining, the machine tool can move simultaneously in three linear axes (X, Y, Z) and two rotary axes (usually A and B or C). This allows the tool to contact the workpiece from almost any direction, enabling precision machining of complex shapes. 5-axis CNC machining offers a higher level of sophistication and precision than traditional 3- or 4-axis CNC machining. 5-axis CNC machining services advantages: 1. easy machining of complex parts; 2. increased accuracy; 3. reduced machining time; 4. improved surface quality; and 5. fewer fixtures and tool changes; Widely used in: aerospace, automotive manufacturing, mould making, medical devices, energy industry, and other precision engineering.

Why Choose Us:

GD-HUB's 5-axis CNC machining services are the perfect choice when precision is critical. With state-of-the-art 20+ 5-axis CNC equipment and a team with over 20 years of experience, we can easily handle everything from prototyping to full production. Our 3-axis and 4-axis milling capabilities, combined with our full 5-axis milling services, allow us to produce highly accurate and high quality parts. GD-HUB offer ISO 2768 (Standard, Fine) and ISO 286 (Class 8, 7, 6) tolerance options and are ISO 9001 certified. In addition, our 5 axis CNC machining services perfectly complement our 3D printing services, making GD-HUB a one-stop manufacturing provider for all your advanced design needs.

ISO certified

ISO certified

CNC Machining Parts with Tight Tolerances

CNC Machining Parts with Tight Tolerances

(Tolerances up to ±0.0004″ (0.01mm)

Fast delivery: 3-15days

Fast delivery: 3-15days

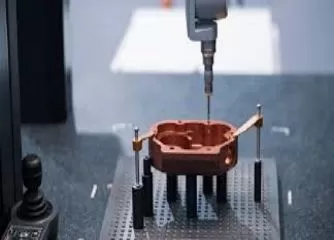

Leading quality inspection and testing

Leading quality inspection and testing

24H/7d Engineering Support

24H/7d Engineering Support

Capabilities of GD-HUB 5-Axis Machining Service

GD-HUB 5-axis CNC machining centers lead the industry with over 20 set 5-axis CNC machines and engineers with over 20 years of experience. Because 5-axis CNC machines allow operators to approach parts from all directions in a single operation, eliminating the need for manual repositioning, high precision, accuracy, and fast production requirements can be achieved, as well as the ability to easily manufacture parts that produce complex geometries with excellent surface finishes.

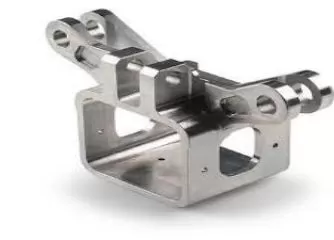

Robotic Parts With 5-axis Machining

The use of 5-axis CNC technology is critical when the precision of robotic components is required, as they must fit together with extreme precision to ensure proper robot operation and performance. Given the complex design and rugged construction of robotic applications, where every millimeter can affect the functionality and efficiency of the system, 5-axis CNC machining services are best suited to meet the fine, precise, high-performance requirements of robotic components.

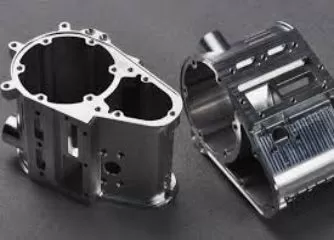

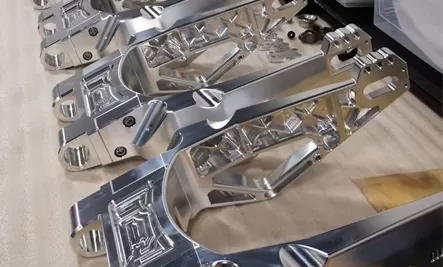

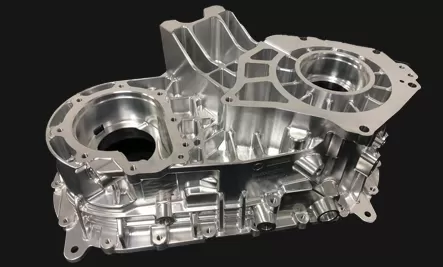

Automotive Part With 5-axis Machining

This particular engine component has a variety of cavities, flanges and structural reinforcements, all of which are integral to its function in the engine assembly. This part GD-HUB was manufactured using 5-axis CNC precision manufacturing technology, demonstrating the high level of detail and complexity that can be achieved with GD-HUB. The precision of the 5-axis CNC machining service is critical to engine components as they must meet stringent specifications to ensure proper engine performance and efficiency.

Automotive Part With 5-axis Machining

Five-axis CNC precision machining plays a vital role in the production of such small parts that require high accuracy. Unlike traditional three-axis machining, which can only operate in three axes, five-axis machines can rotate in two other axes, allowing the tool to approach the workpiece from almost any direction. This allows complex shapes to be machined, such as the workpiece shown here, which has distinctive dark grooves and sharp corners. The precision of 5-axis machining service ensures that these parts meet the tight tolerances necessary for the high quality performance and reliability expected by the automotive industry.

Processable Materials

GD-HUB provides high-precision 5-axis CNC machining services for a wide variety of businesses and industries, that can work with a diverse range of materials, including metals like steel, aluminum, brass, copper, titanium, and magnesium, as well as plastics, ceramics, and other materials. With over 100 production-grade materials available, we can help you find the most match material and solutions for your prototype project. Contact us to discuss your unique requirements and see how we can help.

Related Information

The Benefits of 5-Axis CNC Machining: Unveiling Unparalleled Precision and Efficiency

5-Axis CNC Machining Services: Revolutionizing the Manufacturing Industry

Optimizing CNC Machining: Unveiling the Power of 3-Axis, 4-Axis, and 5-Axis Milling