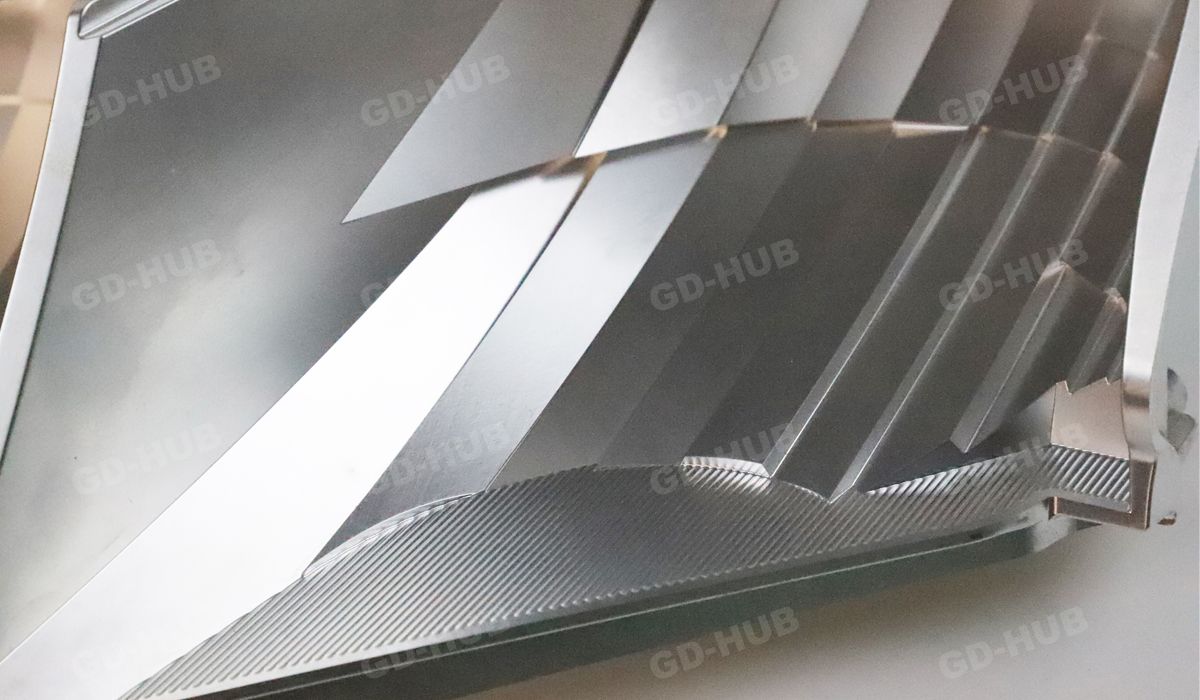

CNC Precision Machining of Automotive Light Reflector Prototypes Of GD-HUB

Details about automotive light reflector prototype project manufacturing

Item | Aluminum reflector for optical testing |

Material | Aluminum alloy 7075 |

Technology | CNC milling (5-axis CNC) |

Details | Optical surface sharpening radius close to CAD data, R0.1mm |

Quality | Light cutter, surface finish Ra0.4, polished up to 0.05um, dimensional accuracy +0.01mm |

5-axis CNC precision machining

Precision machining of automotive light reflectors is a challenging task, but GD-HUB 5-axis CNC ultra-precision machining and extensive experience in manufacturing complex prototypes allow GD-HUB to meet the most difficult manufacturing challenges, fully express every optical detail of your design.

Dimensional error control

Our technical team uses CNC milling technology to manufacture aluminum reflectors for optical testing with optical surface grinding radii close to CAD design data with a dimensional accuracy of +0.01mm .

Post-treatment processing

We also offer optional post-treatment processing, such as mirror polishing and subsequent plating, to achieve a final surface roughness after polishing to Ra(μm) 0.025-0.05 and rounding off sharp external edges does not exceed R0.1mm

Basic Guide to Automotive Reflector Manufacturing

I. Definition of vacuum coating

The so-called vacuum coating refers to the vacuum state. (generally refers to the air pressure in the range of 10-1 ~10-4Pa) to take heating or other means, so that the gold or media material vaporization, deposition in the plated substrate surface, so as to form a thin film layer. The film layer is generally in about 10μm thickness.

II. Classification of plating film

The reflectivity of aluminum reflector: the efficiency of the coating layer reflecting visible light is the highest with vacuum plated dielectric, followed by vacuum plated aluminum, and the lowest with anodic oxidation.

1、Vacuum plating meson: applied to glass reflector. Not only has the highest visible light reflectivity, but the infrared rays generated by the bulb can pass through the meson, which plays a heat dissipation function and prolongs the service life of the bulb.

2, vacuum aluminum plating: aluminum reflectors are applied to temperature-resistant plastic and metal reflectors. High reflectivity is the main coating process for cars and most lamps. The disadvantage is that the light bulb generated by the ultraviolet light will make the reflector whitening, reducing the reflectivity; infrared and can not penetrate the aluminum layer and be reflected back to the bulb, so that the bulb continues to heat up, affecting the service life of the bulb

3, anodic oxidation: applied to the metal reflector. Effective reflectivity is less than half of the vacuum aluminum plating. The advantage is not afraid of ultraviolet light, infrared damage, and can even be cleaned with water.

Ⅲ. Precautions for aluminum reflector

The thickness of aluminum reflector of vacuum aluminum plating process does not exceed 10μm, and it can react chemically to acid and alkali, thus reducing the reflectivity. Reflective cups should not be touched by hand, and should not be cleaned with water.

Fourth, introduce the reflectivity of aluminum reflector and use precautions.

Aluminum reflector with point light source bulb as the light source, the need for long-distance spot lighting reflector, usually cup-shaped, commonly known as reflector.

Spot lighting 3 basic conditions

1, point power bulb. The smaller the luminous body of the light source, the better the spotlighting

2, sophisticated multi-segment focus reflector

3, precision bulb concentric positioning structure

Reflector materials and advantages and disadvantages

Reflector can be made of three materials:

metal, temperature-resistant plastic and glass

1, metal reflector: stamping, polishing process to complete, there is a deformation memory, the advantage of low cost, temperature resistance, commonly used in low lighting requirements of the lamps.

2, plastic reflector: a demoulding process, high optical accuracy, no change memory, moderate cost, the disadvantage is that the temperature resistance is poor, commonly used in the temperature is not high in the flashlight and portable lamps

3、Glass reflector: one time demoulding, high optical precision, invisible memory, temperature resistance, high cost, fragile, heavy weight. Often used in high quality products that do not need to move. Such as movie projectors, searchlights, locomotive lights, etc.

GD-HUB prides on providing excellent support to our customers in the design, development, and manufacture of optical prototypes, including styling review, structural optimization, optical testing, and demonstration vehicle projects.

Contact us now for the best solution for your automotive prototyping project!

Related Knowledge