Our Advantage

With over 20 years of experience serving various industries such as Automotive, Aerospace, Robotics, Telecommunications, Medical device, Industrial Machinery, Consumer electronic and more, we are proud to be one of the top rapid prototyping manufacturers in China.

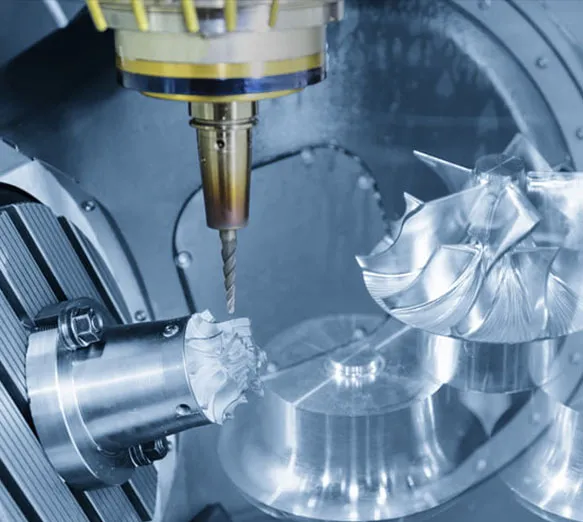

Our 12,000㎡ plant houses over 100 CNC machines and a team of 100 skilled workers and more than 30 engineers who can handle both conventional and technically challenging requirements, including specific surface treatments.

We offer a one-stop service for both prototyping and on demand production, eliminating the need for outsourcing.

We have been exported to over 100 countries worldwide, with a strong presence in Europe, America, and Japan, where we have established partnerships with corporate brands.

Choose us to bring your designs and ideas to life in just a few days.

Nearly 12000 square meters of plant

Nearly 12000 square meters of plant

Our plant covers an impressive area of 12,000 square meters, providing ample space for our operations and services.

More than 80 CNC machine

More than 80 CNC machine

Our facility is equipped to handle large-scale manufacturing projects with precision and efficiency.

More than 100 workers

More than 100 workers

We are one of the best rapid prototyping manufacturer in China with over 20 years of experience in serving automotive and aerospace

30 excellent engineers

30 excellent engineers

Who are highly experienced and skilled in their respective fields. With their expertise, we can guarantee the perfect completion of your project.

Exported to more than 100 countries

Exported to more than 100 countries

We has established a strong reputation and trust with numerous renowned businesses, resulting in deep partnerships with clients across over 100 countries worldwide.

Provide one-stop service

Provide one-stop service

Eliminating the need for you to search for multiple outsourcers. We are committed to providing you with all the services you need in one step.

Factory picture

How To Work With GD HUB

Collaboration Begins

01

Design Concept Assessment

When collaboration begins at GD-HUB, our engineering team will evaluate the feasibility of the part design concept, and other important factors such as material, surface treatment, product structure and other details info provided by the customer at quoting stage carefully. We will communicate with the customer closely to identify any potential issues that may impact the implementation of the part ensuring a smooth production process, strive to minimize errors, determine the final processing method and provide a quote within 6-12 hours.

02

Production Preparation

After engineering team has received the order, Programming, material purchasing, arranging and preparing the orders for machining will be performed at the same time. All incoming materials are inspected. At this stage, our production team will also double check the machinability of the parts and will get back to the customer at the first time if the modification is needed. Our goal is to ensure that the final product is of the highest quality and meets all necessary standards.

During Production

03

Production Inspection

After starting production, we conduct thorough checks during each machining procedure to ensure that any potential issues are caught earlier on and addressed promptly. Will also pay attention to the shrinkage rate, deformation of different materials and give appropriate corrective measures during production in time. Our ultimate goal is to deliver high-quality parts that meet our customers’ specifications and perform flawlessly in their intended applications, meet or even exceed your expectations.

04

Post-Processing

After the processing is completed, we will carry out simple surface treatment on the parts by ourselves, such as deburring, grinding, sandblasting, polishing, etc., if painting, silk screening, tinted, anodization, chroming, passivation, plating and more surface treatment is needed. We'll arrange outsourcing, in order to follow all manufacturing and technical specifications that specified in the 2D drawings. We also prioritize privacy during production and guarantee that your designs and components will not be disclosed to the public.

Final-Inspection

05

Quality Assurance

Once the parts are completed, our quality inspection team will check each part by using measuring equipment like calipers, Height Gauge, CMM and others, to ensure that the parts can meet the specified requirements per the drawing. We also can provide final inspection reports on request. we strictly obey the ISO9001:2015 requirements. Our commitment to quality extends beyond production, ensuring that our customers receive only the best products.

06

Packaging And Delivery

GD-HUB understands the importance of customers expecting to receive their parts exactly and knows the unpredictability of the logistics, to lower the risk to the parts during our package process, we'll use 4 layers of protection. We also take photos of each part before packaging and send with shipment notice for confirmation. After delivery, we'll continue to follow up, ensure that the part meets your requirement and there's no quality issues. You can have complete confidence that GD-HUB will deliver on commitment to quality and reliability.

Hear what our customers say

ML

Marcus Lee

US

Choosing GD-HUB for die casting was the right decision. Their efficiency and precision in producing complex and durable parts were exactly what my project needed.

ET

E Turner

UK

For aluminum extrusion needs, GD-HUB is the best choice. The attention to detail in shaping aluminum for my specific requirements was outstanding.

VW

V Wang

UK

GD-HUB's prototyping services played a crucial role in my product development journey. The rapid prototyping process was not only fast but also incredibly accurate.

LH

L Harper

US

GD-HUB's skill in accurately shaping and forming sheet metal for my sheet metal project in sheet metal fabrication is a testament to their mastery of their craft, exceeding expectations and looking forward to working with them next time.

OM

O Marshall

UK

GD-HUB's vacuum casting services brought my prototypes to life with incredible detail. The consistency and efficiency in producing high-quality casted parts were impressive.

RC

R Chang

US

Rapid tooling is a game-changer in product development, and GD-HUB's services were exceptional. The speed and precision in tooling production were key to the success of my project.

JR

J Rodriguez

US

As a designer, the quality of injection molding is paramount. GD-HUB's injection molding services not only met but exceeded my quality standards.

ST

S Thompson

US

GD-HUB's CNC machining services surpassed my expectations. The precision in crafting intricate components for my project was crucial, and GD-HUB delivered flawlessly.

NH

N Hurtevent

US

Thanks for your effort and push the project sucessfully. I really like what you do and admit I would love to have the next opportunity to work with you with other projects. Your works are really amazing!

Mc

M Covington

Us

A pleasure to work with GD-HUB, my project was completed to a very high standard and it made my market testing go very smoothly! I will trust you with my next requirement!

Customer Distribution Map

US | Canada | Czech Republic | Germany Austria | Belgium | Israel | Finland | Sweden France | Italy | Spain | Australia | Lithuania Poland | Britain | Netherlands | Denmark India | Malaysia | Singapore | Morocco Nepal | Puerto Rico | Japan

Canada US Puerto Rico Peru Sweden Denmark Ireland Poland Netherlands Belgium Britain Finland Germany France Spain lsrael Greece Italy Morocco Turkiye India Nepal Malaysia Japan Singapore Australia