①. What is a Precision Machining vendors

A precision machining vendors is a company or business that specializes in precision machining services like GD-HUB. Precision machining is a manufacturing process used to create highly accurate and complex parts for a variety of industries. These vendors use advanced machining tools and equipment to cut, shape, and machine raw materials (such as metals, plastics, or ceramics) into precise, customized parts to specific design specifications and tolerances.

GD-HUB precision machining serve a variety of industries, including aerospace, automotive, medical, electronics, and more. The parts we produce are critical to the operation of a wide range of products and machinery and play a vital role in the manufacturing process. When choosing GD-HUB Precision Machining, customers often value our reputation for quality, expertise, cost-effectiveness, and meeting strict production deadlines.

②. What does a precision machining vendors's service usually include?

The services provided by a precision machining vendors typically include a full range of machining and related services to meet the specific needs of the customer. The following are the main services that GD-HUB typically provides as a precision machining vendors:

CNC Machining: This is one of the core services offered by GD-HUB as a precision machining vendors. It involves the use of computer-controlled machine tools to perform precision operations such as milling, turning, drilling and grinding. CNC machining is used to create complex, accurate parts from a variety of materials.

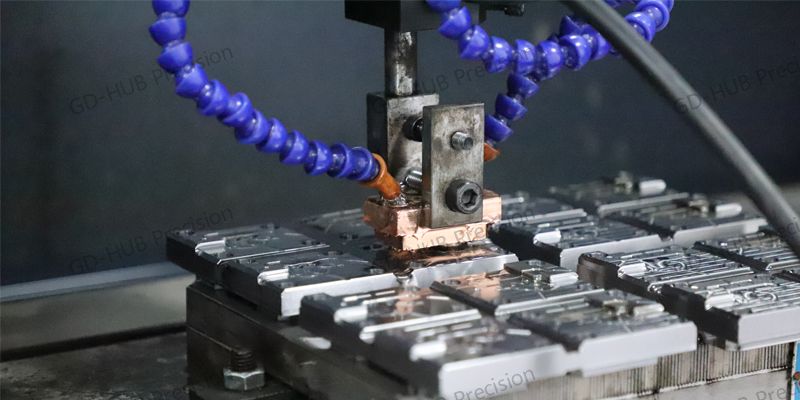

Electrical Discharge Machining (EDM): EDM is a non-traditional machining process that utilizes electrical discharges to remove material. It is used for tasks that require extreme precision and complex shapes, such as making molds and dies.

Grinding: Precision grinding is used to achieve tight tolerances and excellent surface finishes. It is often used to produce precision tools, cylindrical parts and components that require a fine surface finish.

Prototyping: Many precision machining vendors, including GD-HUB, offer prototyping services. We can help customers realize their design concepts by creating prototypes of parts or products for testing and validation.

Production Machining: GD-HUB's ability as a precision machining vendors to handle both low and high volume production ensures that our customers receive the high quality product components they need.

Material Selection and Sourcing: GD-HUB, as a premier precision machining vendors, often assists customers in selecting the right material for a particular application. We can also assist in sourcing the necessary materials to ensure that they meet the required quality standards.

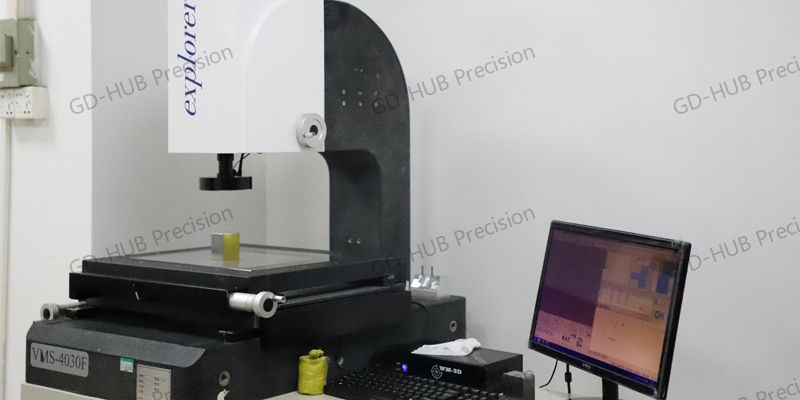

Quality Control and Inspection: GD-HUB prioritizes quality control and inspection as a superior precision machining vendors. We utilize state-of-the-art measuring equipment and rigorous inspection processes to ensure that machined parts meet specified tolerances and quality standards.

CAD/CAM Services: Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) services are available to assist in optimizing designs and programming CNC machine tool operations.

Auxiliary Operations: GD-HUB, as a premier precision machining vendors, can provide additional services such as assembly, finishing (e.g., painting or plating), and packaging in order to deliver a fully finished part or product to the customer.

CUSTOMIZATION AND ENGINEERING SUPPORT: GD-HUB, as a premier precision machining vendors, will work closely with the customer to provide customization services based on specific project requirements. We provide remote engineering support to optimize design manufacturability.

Consulting and Project Management: GD-HUB, as a premier precision machining vendors, also offers consulting services to help customers effectively plan and manage machining projects. This may include cost estimation, project scheduling, and logistics support.

③. As a premier vendors of precision machining, what benefits and advantages can GD-HUB bring to your organization?

1. High Precision and Accuracy: As a premier vendors of precision machining, GD-HUB specializes in producing parts with extremely tight tolerances and high accuracy. This ensures that parts meet the exact specifications required for their intended application, reducing the risk of error and rework.

2. Cost Effectiveness: While precision machining has a higher initial setup cost compared to other manufacturing methods, it often saves companies money in the long run. For example, the precision of CNC machining minimizes material waste, reduces the need for secondary operations, reduces the risk of part defects, and ultimately results in cost savings.

3. Versatility: As a superior precision machining vendors, the GD-HUB can machine a wide range of materials, including metals, plastics, ceramics and composites. This versatility makes them suitable for a variety of industries and applications, from aerospace and automotive to medical devices and electronics.

4. Consistency and Repeatability: Precision machining processes, especially those using CNC machines, allow us to produce identical parts of consistent quality for organizations, even in high volume production. This reliability is critical to maintaining product consistency and performance.

5. Complex Geometry: As a superior precision machining vendors, GD-HUB can produce complex shapes that are difficult or impossible to achieve with other manufacturing methods. This capability is particularly important in industries such as aerospace and medical device manufacturing.

6. Rapid Prototyping: As a premier provider of precision machining, GD-HUB also offers rapid prototyping services that allow companies to quickly test and validate designs before going into mass production. This allows companies to save time and resources in the product development process.

7. Quality Assurance: GD-HUB has strict quality control measures in place to ensure that every machined part meets the required standards and specifications. This helps companies maintain high product quality and reliability.

8. Time Savings: As a premier precision machining vendors, GD-HUB has the expertise, equipment and processes to complete machining projects efficiently. This can lead to faster production turnaround times, helping organizations meet deadlines and get products to market faster.

9. Expertise and support: GD-HUB has highly skilled machinists and engineers, and we can provide valuable input during the design phase to optimize part manufacturability. Our expertise helps organizations make informed decisions about materials and machining processes.

10. Scalability: Whether it's a small batch of customized parts or a large production run, GD-HUB can scale production capabilities to meet the varying needs of your organization.

11. Reduced Capital Investment: Outsourcing precision machining services eliminates the need for organizations to invest in expensive machining equipment and facilities, saving money that can be used in other critical areas of the business.

12. Reduced Risk: GD-HUB is experienced in managing the risks associated with manufacturing, including quality control, material sourcing and production planning. This can help companies reduce operational risk and avoid costly setbacks.

④. As an exceptional precision machining vendors, GD-HUB possesses a range of capabilities and qualities that set it apart from the rest of the industry:

As an exceptional precision machining vendors, GD-HUB possesses a number of capabilities and qualities that set us apart from the rest of the industry. These qualities enable GD-HUB to consistently deliver high quality, accurate and reliable machining services.

1. Technical Expertise: As a premier precision machining provider, GD-HUB has a deep understanding of machining processes, materials and technologies. We are aware of the latest advances in machining and are proficient in the use of a wide range of machining equipment and software.

2. Skilled Workforce: GD-HUB employs highly skilled machinists, engineers and technicians with extensive experience in precision machining. These professionals are able to interpret complex engineering drawings and perform machining operations with precision.

3. Focus on Quality: For GD-HUB, quality is paramount. We have a rigorous quality control process that includes inspections, measurements, and testing to ensure that every machined part meets specified tolerances and quality standards.

4. State-of-the-Art Equipment: As a premier vendors of precision machining, GD-HUB often invests in state-of-the-art machining equipment, including CNC machines, EDM machines, and measuring tools. The equipment is regularly maintained to ensure reliability and accuracy.

5. Design for Manufacturing: GD-HUB provides Design for Manufacturing (DFM) and engineering support to help customers optimize their machining designs and reduce production challenges and costs.

6. Material Expertise: As a premier precision machining vendors, GD-HUB understands a wide range of materials and their processing characteristics. Our specialized technicians can advise customers on material selection based on their specific application requirements.

7. Customization: As a premier precision machining vendors, GD-HUB has the flexibility to customize their processes to meet the unique needs of their customers. We have the ability to take on complex or low volume projects.

8. PROJECT MANAGEMENT: As an exceptional precision machining vendors, GD-HUB has strong project management capabilities, including the ability to estimate project costs, manage production schedules, and provide regular updates to customers.

9. Continuous Improvement: GD-HUB is committed to continuous improvement. We actively seek ways to improve processes, reduce waste and increase efficiency.

10. Communication Skills: Effective communication with customers is critical. As a premier precision machining vendors, GD-HUB maintains open lines of communication and responds clearly and promptly to customer inquiries and project progress updates.

11. Problem Solving: As a premier precision machining vendors, GD-HUB has a problem-solving mindset and is able to respond to unforeseen challenges that may arise during the machining process. We partner with our customers to find solutions.

12. Standards Compliance: As a premier precision machining vendors, GD-HUB adheres to industry standards and is certified in its field to ensure compliance with quality and safety regulations.

13. Scalability: Whether for small prototypes or high volume production, we are able to adapt our production capabilities to the varying needs of our customers.

14. Consistency and Reliability: As a superior precision machining vendors, GD-HUB consistently delivers high quality products and meets project deadlines. Customers can count on GD-HUB's consistent performance over time.

15. ETHICAL AND TRANSPARENT BUSINESS PRACTICES: As an exceptional precision machining vendors, GD-HUB adheres to the principles of honesty, transparency, and fairness in its business dealings. This includes a clear pricing structure and ethical sourcing of materials.

16. Customer Focus: As a premier precision machining vendors, GD-HUB prioritizes customer satisfaction. We listen to customer feedback and work collaboratively to meet or exceed customer expectations.

17. FINANCIAL STABILITY: Financial stability and a proven track record of successful projects are hallmarks of GD-HUB's reputation as a reliable and superior precision machining vendors.

18. CERTIFICATIONS AND ACCREDITATIONS: GD-HUB holds relevant industry certifications and accreditations that demonstrate a commitment to quality and compliance.

As a superior precision machining vendors, GD-HUB combines these capabilities and qualities to provide customers with reliable, high quality, cost-effective machining solutions that contribute to the long-term success of the organization in the industry.

⑤. As a vendors of superior precision machining, what industries can GD-HUB serve?

As a provider of precision machining excellence, GD-HUB can serve a wide range of industries that require high precision machined components and parts.GD-HUB's expertise and capabilities can be applied to a wide range of industries, including but not limited to:

1. Aerospace: Aerospace companies rely heavily on precision machining for critical components in their airplanes and spacecraft, including engine components, landing gear components and instrumentation.

2. Automotive: Precision machining is critical to the production of components such as engine parts, transmission parts, steering systems and braking systems.

3. Medical: The medical industry requires precision machining for surgical instruments, implants, prosthetics, and a variety of medical devices and equipment.

4. Electronics: Precision machining vendors are involved in the manufacture of electronic equipment components including connectors, housings and heat sinks.

5. Defense and Military: Precision machined parts are critical in defense and military applications such as firearms, optics, and vehicle components.

6. Oil and Gas: The oil and gas industry relies on precision machining for components used in drilling equipment, valves and instrumentation.

7. Energy:Precision machining is used to produce components for power generation equipment, renewable energy systems and electrical infrastructure.

8. Telecommunications: Precision machining vendors contribute to the manufacture of telecommunications equipment such as antenna components and connectors.

9. Industrial Equipment: Precision machining plays an important role in the production of industrial machinery and equipment, including pumps, valves and automation components.

10. Transportation: In addition to the automotive and aerospace sectors, precision machining is used in a variety of transportation applications such as rail, marine and public transportation.

11. Packaging: Manufacturers of packaging machinery need to process precision parts for equipment used to package and label products.

12. Semiconductor: The semiconductor industry relies on precision machining to create components used in the manufacture of microchips and electronic devices.

13. Food and Beverage: Precision machining vendors provide parts for food processing and packaging machinery to ensure sanitation and accuracy in the production process.

14. Environmental Technology: Companies involved in environmental technology may require precision machining of components used in water treatment, air pollution control and recycling equipment.

15. Research and Development: Research organizations and laboratories often require custom precision machined parts for experimental devices and scientific instruments.

16. Consumer Goods:The consumer goods industry benefits greatly from precision machining because of the high quality of precision machined parts used in products ranging from appliances to sporting goods.

17. Space Exploration: Precision machining is key to manufacturing components for space exploration missions such as satellites and scientific instruments.

18. Textile and Apparel Machinery: The textile industry relies on precision machining to create mechanical components used in fabric production and apparel manufacturing.

19. Automated Robotics: Precision machined parts are integral to the assembly of robotic systems for manufacturing, logistics and automation.

20. Custom and Niche Markets: In addition to the industries listed above, precision machining vendors may find opportunities in specialized or niche markets, including custom parts for unique applications.