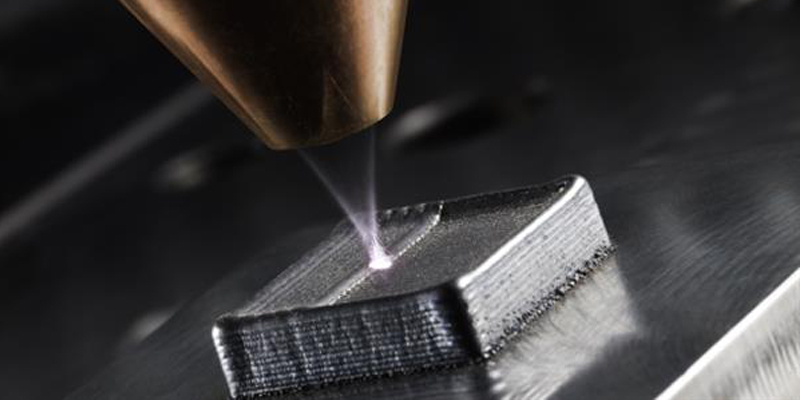

About Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is a specific technique used in additive manufacturing, commonly known as 3D printing. In SLM, a high-power laser is used to fuse small particles of metal powder into a dense, solid structure. This process is typically performed layer by layer, following a digital 3D model, allowing for the creation of complex and detailed geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

SLM is particularly popular in industries where precision and material strength are paramount, such as aerospace, automotive, and medical. This technique enables the production of components with intricate internal structures, reduced weight, and material waste, as well as the possibility for customization and rapid prototyping.

Aerospace and Aviation: SLM is ideal for producing lightweight, strong components for aircraft and spacecraft. This includes parts like turbine blades, structural components, and intricate fuel nozzles. The ability to create complex, optimized structures helps in improving fuel efficiency and reducing weight.

Automotive Industry: In the automotive sector, SLM is used for both prototyping and production of functional parts. It's used for making complex parts like gearboxes, custom components for motorsports, and parts for electric vehicle batteries.

Medical and Dental: SLM is extensively used for medical implants, such as hip and knee replacements, dental implants, and custom surgical tools. The ability to customize these implants for individual patients is a significant advantage.

Energy Sector: In the energy industry, especially in power generation, SLM is used to manufacture parts like impellers, burner nozzles, and other components that can withstand high temperatures and corrosive environments.

Tooling: SLM is used to create complex tooling components, particularly those with internal cooling channels or other features that would be difficult to machine traditionally.

Research and Development: Universities and research institutions use SLM for experimenting with new designs and materials, particularly in fields like material science and engineering.

Consumer Products: Although less common, SLM is also used in the manufacture of high-end, customized consumer products like jewelry, watches, and specialized sporting equipment.

Defense and Military: The defense sector uses SLM for manufacturing lightweight, durable components for vehicles, weaponry, and other defense equipment.

The key advantage of SLM in all these sectors is its ability to produce complex shapes with a high degree of precision, which traditional manufacturing methods cannot easily achieve. Additionally, the technology's ability to optimize material use and reduce waste is particularly valuable in industries where material costs are high or where weight reduction is critical.

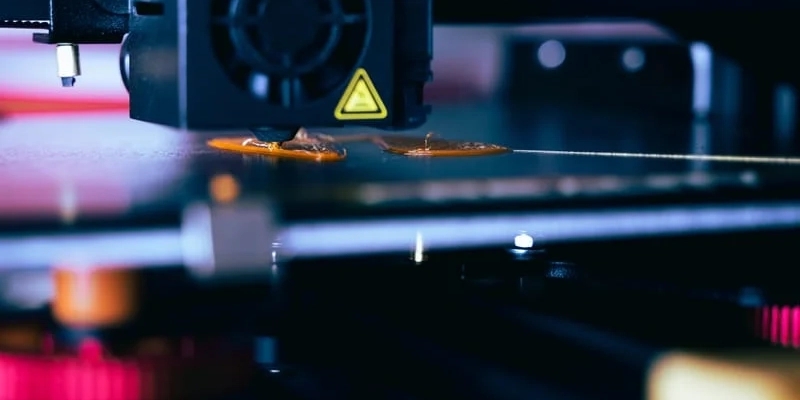

Fused Filament Fabrication (FFF)

Fused Filament Fabrication (FFF), also known as Fused Deposition Modeling (FDM), is a widely used additive manufacturing process. It works by extruding thermoplastic materials to build parts layer by layer.

FFF has revolutionized prototyping and small-scale manufacturing due to its affordability, ease of use, and versatility, making it a go-to choice for a wide range of users, from engineers and designers to educators and hobbyists.

Some of the key applications:

Prototyping: FFF is extensively used for creating prototypes across industries like automotive, aerospace, consumer products, and electronics. It allows designers and engineers to rapidly produce and iterate physical models of their designs.

Educational Models and Tools: In the education sector, FFF is used to create educational models, such as anatomical models in biology, molecular structures in chemistry, and historical artifacts for history lessons.

Custom Tools and Jigs: In manufacturing settings, FFF is utilized to create custom tools, jigs, and fixtures that are used to facilitate the manufacturing process.

Medical Models and Prosthetics: The medical field employs FFF for producing custom prosthetics, orthotics, and patient-specific anatomical models for pre-surgical planning and education.

Consumer Goods: FFF is used in the production of consumer products like custom phone cases, household items, fashion accessories, and personalized toys.

Automotive Components: Some non-critical automotive parts, such as dashboard prototypes, vents, or custom fittings, are manufactured using FFF due to its flexibility in design and rapid production capabilities.

Architectural Models: Architects and designers use FFF to create detailed scale models of buildings and structures for presentations and client reviews.

Hobbyist and DIY Projects: The accessibility of FFF printers has made them popular among hobbyists and DIY enthusiasts for creating custom parts, models, and crafts.

Art and Design: Artists and designers use FFF for creating intricate sculptures, jewelry, and decorative items, leveraging its ability to produce complex shapes.

Drones and Robotics: Parts for drones and robotics, especially in custom or small-scale production, are often made using FFF due to its versatility and ability to produce lightweight components.

Aerospace Components: For low-volume or specialized components, FFF is used to create lightweight parts used in aerospace applications, although these are typically non-critical components due to strength requirements.

Differences between SLM and FFF in processing steps

Processing Step | Selective Laser Melting (SLM) | Fused Filament Fabrication (FFF) |

Design | Starts with a 3D CAD model, often requiring specialized design considerations for metal printing like support structures and thermal stress management. | Begins with a 3D CAD model, design considerations include overhangs, support needs, and layer resolution. |

Material Preparation | Involves handling and preparing metal powders, which may require safety measures due to their reactive nature. | Involves loading a spool of thermoplastic filament into the printer. No special handling required compared to metal powders. |

Machine Setup | Requires setting up a controlled atmosphere, often with an inert gas to prevent oxidation of the metal powders. | Setup typically involves calibrating the printer’s bed leveling and nozzle height. |

Layer Formation | A thin layer of metal powder is evenly distributed across the build platform. | The filament is heated and extruded through a nozzle to form each layer. |

Building Process | A high-power laser selectively melts the metal powder according to the cross-section of the 3D model, layer by layer. | The nozzle moves in a predetermined path to lay down the molten material, building the object layer by layer. |

Post-Processing | Often requires removal of support structures, surface finishing, and sometimes heat treatment to relieve internal stresses. | May include removing support material, sanding for smoother surfaces, and sometimes painting or coating. |

Cooling Time | Parts and the build chamber often need cooling before post-processing due to high temperatures involved. | Generally, cooling is faster; parts can often be removed and post-processed shortly after printing. |

Importance of Selective Laser Melting (SLM)

High-Strength Metal Parts: SLM is vital for producing strong, durable metal parts, which are crucial in industries where material strength and integrity are paramount, such as aerospace, automotive, and medical device manufacturing.

Complex Geometries: SLM allows for the creation of complex and intricate geometries that are often impossible to achieve with traditional manufacturing methods. This capability is essential for optimizing part design for performance and efficiency.

Customization and Personalization: In the medical field, SLM is particularly important for manufacturing customized implants and prosthetic components, tailored to individual patient needs.

Material Efficiency: SLM reduces material waste by using only the amount of material necessary to build the part, which is important for expensive metal powders like titanium and stainless steel.

Rapid Prototyping and Production: It enables rapid prototyping and production of parts, significantly reducing the time and cost associated with traditional manufacturing methods.

Importance of Fused Filament Fabrication (FFF)

Accessibility and Education: FFF is widely accessible and relatively easy to use, making it ideal for educational purposes, hobbyists, and small businesses. It has been instrumental in democratizing 3D printing technology.

Rapid Prototyping: FFF is excellent for quick and cost-effective prototyping, allowing designers and engineers to iterate designs rapidly.

Custom Tools and Components: It's used extensively for producing custom jigs, fixtures, and non-critical components in manufacturing settings, aiding in the efficiency of production processes.

Material Variety: FFF can utilize a wide range of thermoplastic materials, each offering different properties, which is essential for various applications, from consumer products to functional prototypes.

Low-Cost Manufacturing: For small-scale production and custom items, FFF offers a low-cost manufacturing solution compared to traditional methods.

Creativity and Innovation: FFF fosters creativity and innovation, allowing individuals and companies to experiment and create unique designs without the need for expensive tooling or setups.

In summary, SLM and FFF are important in different aspects of manufacturing and prototyping. SLM is crucial for high-strength, precision metal parts, particularly in high-tech industries, while FFF is key in education, prototyping, and the production of plastic parts where cost, accessibility, and material variety are important. Both technologies contribute significantly to the advancement of additive manufacturing, offering distinct benefits that complement traditional manufacturing methods.

Differences between SLM and FFF material applications

Feature | Selective Laser Melting (SLM) | Fused Filament Fabrication (FFF) |

Type of Material | Metal powders (e.g., stainless steel, titanium, aluminum, nickel alloys) | Thermoplastic filaments (e.g., ABS, PLA, PETG, TPU) |

Material Properties | High strength, durability, heat resistance | Varies widely; generally less strong and heat resistant than metals |

Material State | Fine powder | Solid filament |

Melting Point | High (depends on metal used) | Lower (depends on thermoplastic used) |

Post-Processing | Often requires additional post-processing like heat treatment, machining | May require sanding or chemical smoothing for finish |

Surface Finish Quality | Generally smooth, but can be rough depending on the parameters and metal used | Layered finish, often requires post-processing for smoothness |

Density of Finished Product | High, near-solid density | Can vary, typically less dense than metal parts |

Cost of Materials | Higher, due to the cost of metal powders | Lower, thermoplastics are generally cheaper |

This table outlines the differences in the materials used in SLM and FFF. SLM materials are high-strength metals suitable for robust and critical applications, whereas FFF materials are versatile thermoplastics used for a wide range of less critical applications. The choice between these two methods depends on the requirements of the final product in terms of strength, precision, surface finish, and cost.

Differences between Selective Laser Melting (SLM) and Fused Filament Fabrication (FFF) Benefits

Aspect | Selective Laser Melting (SLM) | Fused Filament Fabrication (FFF) |

Industries | Aerospace, Automotive, Medical, Defense, High-Performance Engineering | Consumer Products, Education, Prototyping, Hobbyist Projects, Non-critical Automotive Parts, Architecture |

Components | Aerospace parts (turbine blades, fuel nozzles), Automotive components, Medical implants, High-stress engineering components | Prototypes and models, Educational and DIY tools, Consumer goods, Custom jigs and fixtures, Architectural models |

Precision & Complexity | High precision and complexity for intricate designs and high-stress applications | Moderate precision, suitable for less complex geometries and non-critical applications |

Strength & Durability | High-strength, durable, suitable for load-bearing parts | Variable strength and durability, generally less robust than metal parts |

Cost | Higher due to material and process complexity | Lower, accessible for small-scale production and personal use |

Lead Time | Longer due to complex processing and post-processing requirements | Shorter, ideal for rapid prototyping and small batch production |

Customization | High level of customization for medical and aerospace applications | High level of customization for personalized or unique designs |

Surface Finishing | Often requires post-processing for desired finish; can achieve smooth surfaces with additional treatments like polishing or machining | Layered finish, might require sanding, acetone smoothing, or painting for aesthetic improvement |

SLM is predominantly used in sectors requiring high-strength, precision, and complex metal parts, such as aerospace and medical industries. In contrast, FFF is widely used for prototyping, educational purposes, and manufacturing of non-critical consumer and industrial products, offering flexibility and cost-effectiveness.

Commonly surface finishing between SLM and FFF

Surface Finishing Aspect | Selective Laser Melting (SLM) | Fused Filament Fabrication (FFF) |

Initial Surface Quality | Rougher surface due to the nature of powder fusion, might have some porosity | Layered appearance with visible lines and minor imperfections |

Sanding/Grinding | Often required to smooth out surfaces; can be manual or machine-assisted | Commonly used to reduce layer lines and improve smoothness |

Polishing | Used to achieve a high level of smoothness and shine, especially for aesthetic or functional purposes | Less common but can be used for smooth, glossy finishes on certain materials |

Heat Treatment | Can be used to relieve internal stresses and improve mechanical properties | Not typically used due to the lower melting point of thermoplastics |

Chemical Smoothing | Less common due to the nature of metals | Acetone vapor (for ABS) or similar solvents can smooth surfaces and reduce layer visibility |

Coating | Metal parts can be coated for corrosion resistance, improved hardness, or aesthetic purposes | Paints, epoxies, or other coatings are often applied for aesthetic purposes or to protect the part |

Machining | Additional machining might be necessary for precision features or complex geometries | Less common, but can be used for achieving precise dimensions or features |

Summary

Both SLM and FFF are pivotal in modern manufacturing, offering unique benefits: SLM for its strength and precision in metal parts, and FFF for its accessibility and versatility in plastic part production.

Understanding the differences between SLM and FFF, their characteristics, applications and finish options is key to selecting the right process for a particular application.

GD HUB specialises in the additive manufacturing sector. With our state-of-the-art 3d printers and experienced team, we can produce high quality printed parts with tight tolerances and smooth surface finishes. Whether you need a single prototype or mass production, we can provide the best 3d printing solutions and 3d printing services for your printed parts. Contact us today for a quote!

FAQs

How strong are the parts made using SLM?

Parts made using SLM are very strong, often comparable to those made through traditional manufacturing methods, and suitable for high-stress applications.

What industries benefit most from SLM technology?

Aerospace, automotive, medical (for implants and prosthetics), and high-performance engineering industries benefit significantly from SLM.

What are the limitations of SLM compared to traditional manufacturing?

SLM can be more expensive, has limitations in terms of size, and requires significant post-processing.

Can SLM be used for mass production?

While possible, SLM is generally not the most cost-effective choice for mass production due to its slower speed and higher material costs.

What post-processing is required for SLM parts?

Typical post-processing includes removing support structures, surface finishing (like sandblasting or polishing), and sometimes heat treatment.

What is the typical surface finish of SLM parts?

The surface finish can be somewhat rough and may require post-processing for smoothness or specific tolerances.

Are there specific design considerations when using SLM?

Yes, considerations include accounting for thermal stresses, support structures, and the layer-by-layer building process.

What types of materials can be used in FFF?

Common materials include thermoplastics like ABS, PLA, PETG, and TPU, along with specialized composite filaments.

How does the strength of FFF parts compare to injection-molded parts?

FFF parts are generally less strong than injection-molded parts, particularly along the layer lines, but material choice and print settings can optimize strength.

What are the common applications of FFF?

Common applications include prototyping, educational models, hobbyist projects, and non-critical functional parts.

What are the limitations of FFF in terms of precision and detail?

FFF can struggle with extremely fine details and may have lower dimensional accuracy compared to other additive manufacturing methods.

Is FFF cost-effective for prototyping?

Yes, FFF is highly cost-effective for prototyping due to its low material and operating costs.

Can FFF be used for producing functional parts?

Yes, FFF can produce functional parts, particularly for non-critical applications or where the material properties of thermoplastics are sufficient.

What kind of surface finish can be expected from FFF?

FFF parts typically have a layered appearance and may require post-processing (like sanding or acetone smoothing) for a smoother finish.

How does layer height affect the quality of FFF prints?

Lower layer heights can improve surface finish and detail but increase print time.

What post-processing methods are typically used for FFF parts?

Common methods include sanding, solvent smoothing (for certain plastics), painting, and applying coatings or sealants for appearance or durability.