Quality Assurance (QA) plays a vital role in rapid prototyping, ensuring that the final product meets the required standards and customer expectations. From initial design verification to final product testing, QA activities help identify and resolve any issues or defects throughout the prototyping process. GD-Hub, a leading rapid prototyping service provider, prioritizes high quality standards by implementing a number of practices in our services.

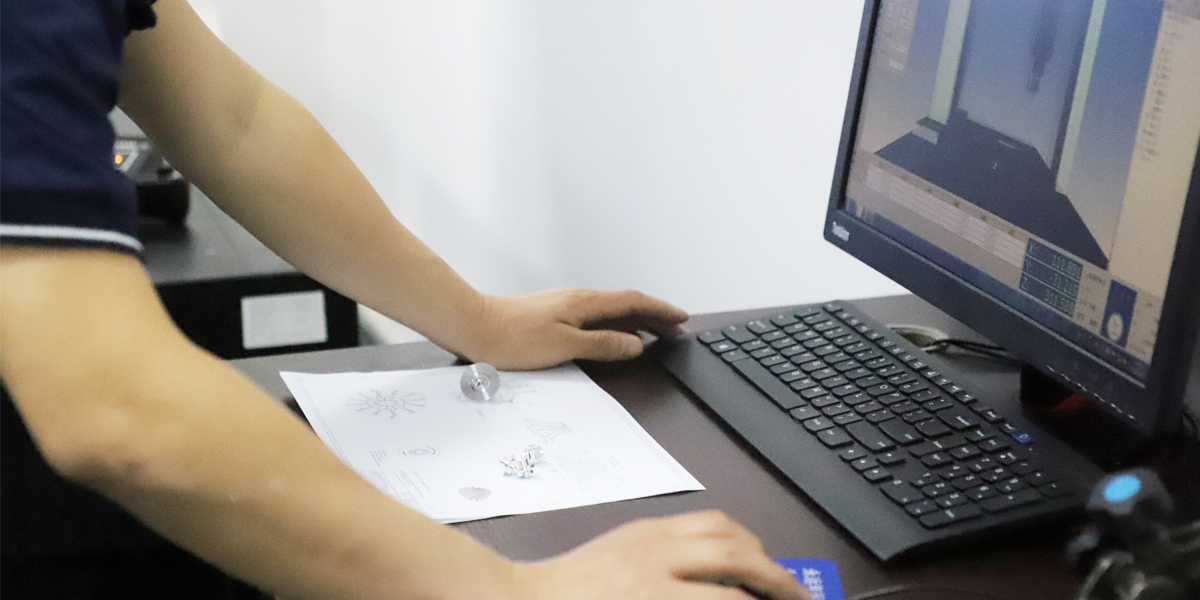

Initial Design Verification:

The quality assurance process begins with a thorough evaluation of the initial design concept. GD-Hub verifies the feasibility of the design and its conformance to the client's requirements. This step includes a careful examination of the design for any potential defects, compatibility issues, or manufacturing challenges.

Material and Component Testing:

Quality assurance for additive manufacturing includes testing the materials and components used in the manufacturing process. GD-Hub ensures that all materials meet the necessary quality standards and are suitable for the intended purpose. Various tests such as stress tests, durability tests and compatibility tests are performed to evaluate the performance and reliability of materials and components.

Iterative Prototyping:

Rapid prototyping typically involves multiple iterations and incremental improvements. During each iteration, QA is integral to evaluating the prototype, identifying any defects and making recommendations for improvement. GD-Hub employs a rigorous review process, including experienced QA engineers, to detect and correct design defects, functional issues, or any deviations from expected specifications.

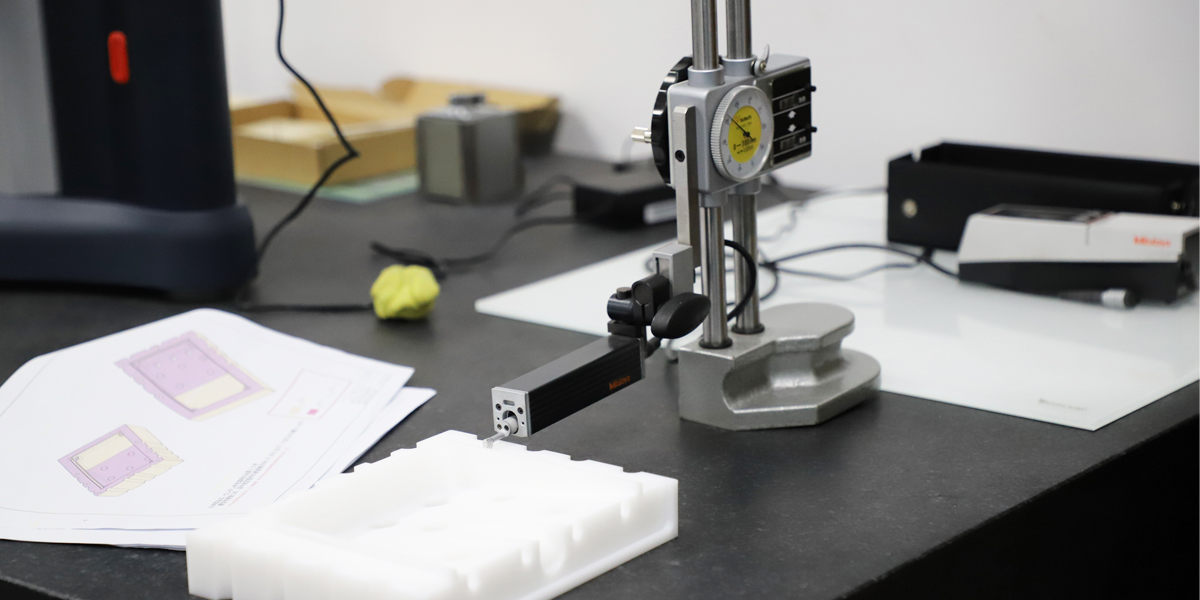

Manufacturing Process Monitoring:

GD-Hub maintains a keen focus on the manufacturing process to ensure the consistency and quality of prototypes. We employ various monitoring techniques such as statistical process control to monitor key parameters and detect any deviations that may affect the quality of the final product. Regular inspections and audits are conducted to maintain compliance with established quality control procedures.

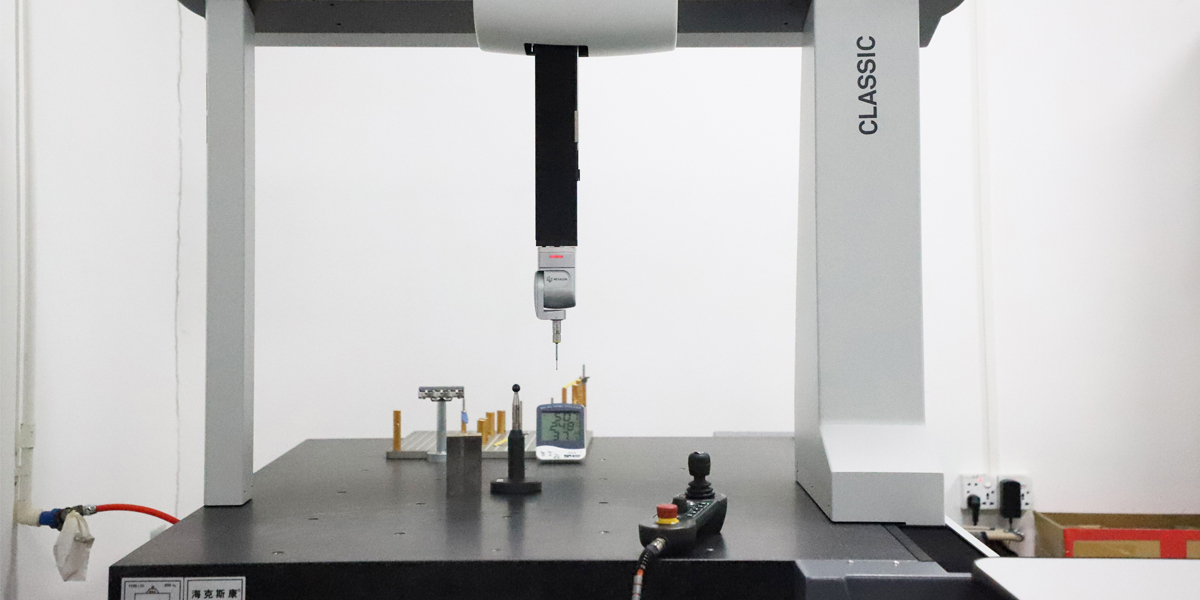

Final Product Testing:

Before delivering a prototype, GD-Hub conducts comprehensive testing to verify the functionality, performance and reliability of the final product. This includes functional testing, stress testing, environmental testing, and any other relevant testing based on product requirements. These tests help to identify any remaining issues and ensure that the product meets the necessary quality standards.

Continuous Improvement:

GD-Hub emphasizes continuous improvement of its services. Customer feedback as well as internal evaluations are used to identify areas for improvement in the prototyping process. Lessons learned from previous projects and industry best practices are incorporated into our quality assurance framework, allowing GD-Hub to continually improve the overall quality of our services.

Compliance with standards and regulations:

GD-Hub ensures that all prototypes are compliant with relevant industry standards and regulations. They are constantly updated with the latest requirements and guidelines to ensure compliance during the design and manufacturing phases. This commitment to compliance helps GD-Hub to deliver prototypes that meet the necessary safety, reliability and regulatory standards.

By following these practices, GD-Hub maintains high quality standards throughout the rapid prototyping process. Our focus on design verification, materials testing, iterative improvement, manufacturing process monitoring, thorough testing, continuous improvement, and compliance with standards ensures that customers receive prototypes that are reliable, functional, and meet their specific requirements.