Ⅰ. Understanding the importance of quality in precision manufacturing.

Quality is not just a desirable aspect of precision manufacturing; it is the cornerstone upon which the entire process and industry rest.

Meeting Strict Tolerances: Precision manufacturing involves producing components or products with extremely tight tolerances, often measured in micrometers or even nanometers. Any deviation from these tolerances can render the part unusable or compromise its performance.

Product Reliability: Many industries that rely on precision manufacturing, such as aerospace, automotive, and medical devices, produce critical components that must function with utmost reliability. Quality assurance ensures that these components perform as expected, reducing the risk of failures, accidents, or product recalls.

Customer Expectations: Precision manufacturing customers, particularly in industries like medical devices or electronics, have high expectations for product quality. Failure to meet these expectations can result in a loss of customer trust and reputation damage.

Cost Savings: Quality control measures, when implemented effectively, reduce the likelihood of defects and rework. This, in turn, leads to cost savings by minimizing material wastage, labor hours, and the need for additional resources to correct errors.

Competitive Advantage: Consistently delivering high-quality products gives companies a competitive edge in the market. Customers are often willing to pay a premium for quality, and a strong reputation for precision and reliability can attract new clients and retain existing ones.

Safety: In industries where precision manufacturing is critical, such as healthcare or aerospace, subpar quality can compromise safety. Ensuring that products meet rigorous quality standards is essential for avoiding safety-related incidents.

Regulatory Compliance: Many industries, including medical devices, pharmaceuticals, and aerospace, are subject to strict regulatory standards and compliance requirements. Quality control is essential to meet these regulations and avoid legal issues.

Brand Reputation: A single quality issue can tarnish a brand's reputation and lead to significant financial losses. Building and maintaining a reputation for quality can take years, but it can be damaged in an instant due to a quality-related incident.

Continuous Improvement: Embracing quality as a fundamental aspect of precision manufacturing promotes a culture of continuous improvement. It encourages companies to seek out inefficiencies, identify areas for enhancement, and refine their processes.

Traceability: Quality control processes often include detailed record-keeping and traceability measures. This allows manufacturers to trace the origin and history of each component, making it easier to address issues and ensure accountability.

The importance of quality in precision manufacturing cannot be separated from the core objectives of the industry: to produce highly accurate, consistent, and reliable products or components. Quality assurance is not merely a box to check but a fundamental principle that permeates every aspect of precision manufacturing, from design and materials selection to production and inspection. It is the linchpin that upholds the integrity and value of precision manufacturing across various industries.

Ⅱ. The role of design in precision manufacturing

Specification and Tolerance Setting: Designers are responsible for specifying the exact dimensions, tolerances, and material properties of a product or component. These specifications are critical in precision manufacturing because they determine the level of accuracy and precision required in the manufacturing process.

Geometry and CAD Modeling: Designers use computer-aided design (CAD) software to create 3D models of the product or component. These digital models provide a precise representation of the final product, including its shape, size, and features. CAD models serve as the foundation for the manufacturing process, guiding machining operations and ensuring dimensional accuracy.

Material Selection: Designers must carefully select materials that meet the desired performance criteria. The choice of materials can significantly impact the precision manufacturing process, as different materials have varying properties, such as thermal expansion rates and hardness, that affect machining and assembly.

Tool and Fixture Design: Precision manufacturing often requires specialized tools and fixtures to hold and manipulate workpieces during machining. Designers play a key role in designing these tools and fixtures to ensure they are robust, reliable, and capable of maintaining tight tolerances.

Optimization for Efficiency and Cost: Designers aim to optimize product designs for manufacturing efficiency and cost-effectiveness. This may involve minimizing complex features that are difficult or expensive to manufacture or finding ways to reduce waste in the production process.

Quality Assurance and Inspection: Designers also need to consider how the product or component will be inspected for quality control. They may design features that facilitate easy measurement and inspection, and they specify the inspection methods and tolerances that must be met during manufacturing.

Prototyping and Testing: Before full-scale production, prototypes are often created to validate the design and manufacturing processes. Designers may work closely with engineers and machinists to refine the design based on the results of prototyping and testing.

Collaboration: Collaboration between designers, engineers, and machinists is crucial in precision manufacturing. Effective communication and cooperation ensure that the design intent is accurately translated into the final product.

Continuous Improvement: Precision manufacturing is an iterative process, and designers play a role in continuous improvement efforts. They analyze manufacturing data, identify opportunities for refinement, and update designs as needed to enhance product quality and efficiency.

Documentation: Detailed design documentation, including drawings, specifications, and manufacturing instructions, is essential for precision manufacturing. This documentation provides a clear reference for machinists and assemblers, helping them achieve the desired precision.

Design is integral to precision manufacturing, guiding the entire process from concept to production. Precise and well-thought-out designs are essential for achieving the high levels of accuracy, consistency, and quality that characterize precision manufacturing.

Ⅲ. Key Principles of GD-HUB Precision Manufacturing

Advanced Material Selection: Material selection is critical in precision manufacturing. It is important to select quality materials with consistent properties to ensure the required performance and accuracy. Material properties, such as thermal expansion, hardness and electrical conductivity, must be well suited to the application.

Tight Tolerance Control: Precision manufacturing relies on tight tolerances, the allowable deviations of dimensions. Tolerances are specified in the design and closely monitored during production to ensure that the finished product meets the required accuracy standards.

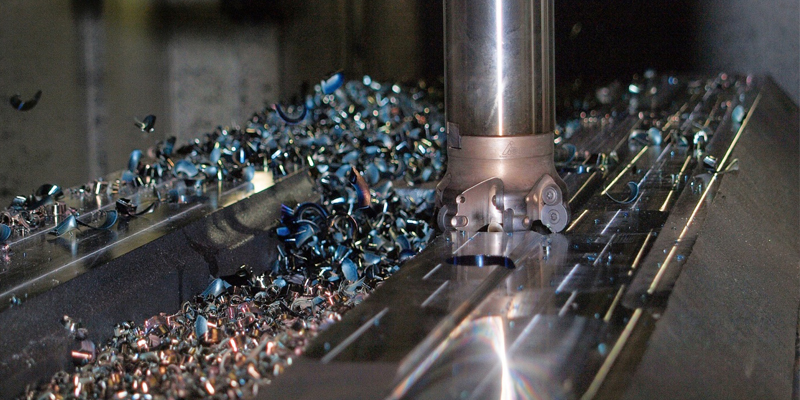

Advanced Machining Technologies: Precision machining processes, such as CNC (Computer Numerical Control) machining and EDM (Electrical Discharge Machining), are used to shape and machine high-precision parts. These techniques produce intricate geometries and minimize errors.

Metrology and Inspection: Metrology is the science of measurement and plays a vital role in precision manufacturing. Advanced measurement tools and techniques, such as Coordinate Measuring Machines (CMM) and laser scanning, are used to verify that parts conform to specified dimensions and tolerances.

Process Control: Rigorous process control methods are implemented to minimize variability and errors in the manufacturing process. This includes monitoring and controlling factors such as temperature, humidity, tool wear and machine calibration.

Advanced Tooling and Fixturing: Specialized tools and fixtures are designed and used to hold workpieces during the machining process. These fixtures are precision-engineered to minimize vibration, misalignment, and other sources of error in the production process.

Lean Manufacturing: Lean manufacturing principles are often applied to precision manufacturing to eliminate waste, reduce production variability and increase efficiency. This includes optimizing processes, minimizing setup times, and ensuring the smooth flow of materials and information.

Quality Assurance and Continuous Improvement: Quality control measures are integrated into every step of the production process. Statistical Process Control (SPC) techniques are often used to monitor and maintain product quality. Continuous improvement measures are also used to identify and resolve problems, improving overall efficiency and accuracy.

Documentation and Traceability: Thorough documentation is maintained throughout the production process, including detailed drawings, specifications and work instructions. This documentation ensures that each step is traceable and repeatable, promoting consistency and quality control.

Skilled Technicians: A well-trained and skilled workforce is critical to precision manufacturing. Operators and technicians must have the knowledge and expertise to operate state-of-the-art machinery and perform complex tasks with precision.

Risk assessment and mitigation: Identifying potential sources of error and risk in the manufacturing process is critical. GD-HUB will conduct risk assessments and develop mitigation strategies to prevent defects and specification deviations.

Ⅳ. Advanced technologies in GD-HUB precision manufacturing

Precision manufacturing has significantly benefited from advanced technologies that have emerged in recent years. These technologies have enabled GD-HUB to achieve even higher levels of accuracy, efficiency, and quality in their processes.

Computer Numerical Control (CNC) Machining: CNC machines use computer programs to control the movement of cutting tools and workpieces with high precision. They allow for complex and intricate part geometries and can work with various materials, including metals, plastics, and composites.

Additive Manufacturing (3D Printing): Additive manufacturing technologies, such as selective laser sintering (SLS) and stereolithography (SLA), build parts layer by layer. This approach is used for rapid prototyping and the production of complex components with minimal waste.

Electrical Discharge Machining (EDM): EDM techniques, including wire EDM and sinker EDM, use electrical discharges to remove material with extreme precision. This is particularly useful for parts with intricate shapes and hard-to-machine materials.

Laser Cutting and Welding: Lasers are used for cutting and welding materials with high precision. Laser cutting is common in the fabrication of sheet metal components, while laser welding is used for joining materials without physical contact.

Precision Grinding: Advanced grinding machines with high levels of automation are used for achieving tight tolerances and fine surface finishes. These machines use abrasives to remove material and refine part dimensions.

Coordinate Measuring Machines (CMMs): CMMs are advanced metrology devices that use computer-controlled probes to measure the dimensions and geometries of parts. They are used for quality control and ensuring that parts meet specified tolerances.

Advanced Robotics: Robots are employed in precision manufacturing for tasks such as assembly, inspection, and material handling. Collaborative robots (cobots) can work alongside human operators and enhance overall productivity.

Advanced Materials: Precision manufacturing often involves the use of advanced materials like ceramics, composites, and superalloys. These materials offer unique properties but require specialized processes and tooling.

Artificial Intelligence (AI) and Machine Learning: AI and machine learning algorithms are employed for process optimization, defect detection, and predictive maintenance. These technologies can identify patterns and anomalies in data to improve manufacturing outcomes.

Digital Twin Technology: Digital twins are virtual representations of physical objects or systems. In precision manufacturing, digital twins are used to simulate and optimize processes, predict performance, and troubleshoot issues before they occur in the real world.

These advanced technologies are continually evolving and are often integrated into integrated manufacturing systems to enhance precision, efficiency, and quality.

Ⅴ. GD-HUB Quality Control Measures in Precision Manufacturing

Quality control measures are critical in precision manufacturing to ensure that a product or component meets the required specifications and standards for accuracy, consistency and reliability.

Design and Specification Review: Before production begins, the design and specifications are thoroughly reviewed to ensure that they are clear, workable and meet the desired accuracy requirements. Any ambiguities or potential problems are resolved at this stage.

Material Inspection: Raw materials are quality checked to ensure that they comply with the specified material properties, such as composition, hardness and thermal properties. Suppliers often provide material certificates to verify the quality of the material.

In-process inspection: In-process inspections are performed throughout the manufacturing process to monitor critical dimensions, tolerances and other quality parameters. This may require the use of specialized measuring equipment and gauges.

Coordinate Measuring Machines (CMM): CMMs are advanced metrology devices used to measure the dimensional accuracy of parts. They use computer-controlled probes to collect precise data points and compare them to CAD models or design specifications to ensure compliance.

Statistical Process Control (SPC): SPC techniques involve continuously monitoring critical process parameters and using statistical analysis to detect trends and changes. Control charts and statistical tools help determine when the process is deviating from expected performance.

Gauge Repeatability and Reproducibility (GR&R) Studies: GR&R studies evaluate the capability and reliability of measurement equipment and operators. They determine if the measurement system can consistently and accurately assess product quality.

First Article Inspection (FAI): First Article Inspection (FAI) is the inspection of the first product or prototype produced to ensure that it meets design specifications. This is especially important for new products or changes to existing products.

Tool and Equipment Calibration: Regular calibration of tools, fixtures and equipment is critical to maintaining the accuracy and reliability of the manufacturing process. Calibration programs and records can be used to track equipment performance.

Quality Documentation: Comprehensive documentation including drawings, work instructions and inspection reports are maintained throughout the manufacturing process. These documents provide a clear record of quality control activities and aid in traceability.

Non-Destructive Testing (NDT): Non-destructive testing techniques such as ultrasonic, X-ray and magnetic particle inspection are used to identify defects or inconsistencies in materials and welds without damaging the product.

Root Cause Analysis: When a defect or quality problem is identified, root cause analysis techniques are used to determine the root cause. Corrective and preventive actions are then implemented to address these issues.

Quality Audits: Internal and external quality audits are conducted periodically to assess compliance with the quality management system and industry standards. These audits help identify areas for improvement and ensure that quality control measures are being followed.

Training and Skills Development: Employees are trained in quality control procedures and techniques to ensure they are able to perform their duties effectively. Ongoing skills development programs are often implemented to keep employees up-to-date with the latest quality control methods.

Implementing these quality control measures is critical to achieving and maintaining the high levels of accuracy and quality required in precision manufacturing industries such as aerospace, automotive, medical devices and electronics. By continually monitoring and improving processes, GD-HUB is able to provide our customers with reliable and accurate products.

Ⅵ. Benefits of GD-HUB Precision Manufacturing for Businesses

GD-HUB Precision manufacturing offers several significant advantages to businesses in a wide range of industries. These benefits contribute to increased efficiency, cost savings, product quality and competitiveness.

Improved Product Quality: GD-HUB Precision manufacturing ensures that a product or component meets extremely tight tolerances and specifications. This produces a consistently high quality product that is less susceptible to defects or variation, reducing the likelihood of recalls and warranty claims.

Improved Product Performance: GD-HUB Precision manufactured components and products tend to perform better. They are more reliable, durable and efficient, resulting in increased customer satisfaction and brand reputation.

Cost Savings: While precision manufacturing may require an initial investment in advanced machinery and technology, it often results in long-term cost savings. Lower scrap rates, reduced rework and increased productivity contribute to overall cost effectiveness.

Increased Efficiency: Precision machining processes such as CNC machining and EDM are highly automated and optimized for efficiency. This results in faster production times, shorter lead times, and increased throughput, GD-HUB helping organizations meet customer needs more efficiently.

Competitive Advantage: GD-HUB that specialize in precision manufacturing can gain a competitive advantage in their respective markets. We can offer high-quality, precision-engineered products that command a premium price or attract a loyal customer base. Even the ability to consistently produce high-quality components or products can expand a company's market reach, allowing it to compete on a global scale.

Customization and Complexity: GD-HUB Precision manufacturing can produce highly complex and customized parts and products. This flexibility allows companies to meet unique customer requirements and enter niche markets.

Compliance and Certification: Many industries have stringent quality and safety standards that must be met. GD-HUB Precision manufacturing processes often align well with these standards, making it easier for companies to gain compliance and certification.

Lean Manufacturing: GD-HUB Precision manufacturing often employs lean principles such as waste reduction and process optimization. This can streamline operations, shorten lead times and improve resource utilization.

Reduced Labor Costs: Automation and advanced machining techniques in GD-HUB precision manufacturing can reduce the need for large amounts of labor, thus helping to control labor costs and minimize the impact of labor shortages.

Data Driven Decision Making: GD-HUB Precision manufacturing often involves data collection and analysis. This data can be used to make informed decisions about process improvement, quality control and resource allocation.

Ⅶ. Choosing a Precision Manufacturing Partner - GD-HUB

Choosing the right precision manufacturing partner is a critical decision that can have a significant impact on the success of your project or business. Whether you are looking for a supplier to precision manufacture parts, products or prototypes, here are a few key factors to consider when selecting a manufacturing partner:

1. Expertise and specialization:

Look for a manufacturing partner with specialized knowledge and expertise in a particular industry or product type. Having experience in a niche area provides a better understanding of your needs and potential challenges.

2. Capabilities:

Evaluate the capabilities of your manufacturing partner, including the range of services offered by the manufacturer, the types of materials used, and the precision machining technologies employed (e.g., CNC machining, 3D printing, EDM).

Ensure that they have the equipment and facilities needed to meet project requirements.

3. Quality control and certification:

Ask about their quality control processes and certifications (e.g., ISO 9001). Ask for examples of their quality records and any relevant industry-specific certifications.

Ask for their quality control documentation and inspection reports.

4. References and reputation:

Request testimonials and case studies from repeat customers with similar program requirements.

Check online reviews and testimonials to gauge their reputation and reliability in the industry.

5. Production capacity and lead time:

Determine if the production partner has the capacity to handle your project volume and meet your required lead times.

Discuss lead times and production schedules to ensure they align with your project timeline.

6. Communication and Collaboration:

Assess their willingness and ability to communicate effectively. Clear and open communication is critical to the success of your project.

Assess their level of collaboration and willingness to work closely with your team to address challenges and make improvements.

7. Cost and pricing structure:

Get detailed quotes and pricing information. Ensure that the pricing structure is transparent and competitive within the industry.

Be cautious of very low cost suppliers as they may reduce quality.

8. Prototyping and testing capabilities:

If prototyping and testing are part of the project, ensure that the production partner has the required capabilities and equipment for these phases.

9. Intellectual property protection:

Discuss and establish clear intellectual property and confidentiality terms to protect your design and proprietary information.

10. Flexibility and customization:

Evaluate the partner's flexibility in accommodating design changes, customization, and small production runs as necessary.

11. Financial Stability:

Evaluate the financial stability of the production partner to ensure they are a reliable long-term partner.

12. Scalability:

Consider whether the production partner can scale up production to accommodate your future growth and changing needs.

13. Factory visits:

When possible, tour the production facility to see their operations firsthand, meet their team, and evaluate their equipment and processes.

14. Contracts and agreements:

Develop a clear, comprehensive contract or agreement that outlines expectations, responsibilities, pricing and timelines.

GD-HUB will be your partner in excellence and loyalty.

The future of precision manufacturing is marked by innovation, sustainability and adaptability. Technological advances will continue to drive the industry forward, enabling greater precision, efficiency and customization. As global challenges such as climate change and supply chain disruptions evolve, precision manufacturing will play an important role in addressing these issues while meeting rapidly changing market demands. Companies that embrace these trends and invest in advanced technology and workforce development will be well positioned for the future of precision manufacturing.