The Past and Future of Precision Manufacturing in the Medical Device Industry

Precision manufacturing has played a significant role in advancing the medical device industry, enabling the creation of intricate and highly functional devices that have revolutionized healthcare. This trend is expected to continue into the future with even more advanced technologies and innovative applications.

Past:

Precision manufacturing in the medical device industry has a rich history. Traditional manufacturing techniques, such as machining and casting, were initially used to produce simple medical devices like surgical instruments and prosthetics. However, as technology evolved, so did manufacturing methods.

The introduction of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems allowed for more precise and efficient production of medical devices. These technologies enabled manufacturers to create complex shapes and designs with higher accuracy, leading to improved performance and patient outcomes. The use of materials like titanium and biocompatible polymers further enhanced the safety and longevity of medical devices.

Present:

In the present day, precision manufacturing techniques have significantly advanced in the medical device industry.

Additive Manufacturing (3D Printing): 3D printing has transformed the medical device industry by allowing for the creation of patient-specific implants, prosthetics, and surgical instruments. This technology enables complex geometries and customization, improving the fit and functionality of devices.

Microfabrication: Microfabrication techniques are used to create micro-scale medical devices such as microfluidic devices for diagnostic purposes, miniature sensors, and tiny implants. These devices can have applications in drug delivery, diagnostics, and minimally invasive procedures.

Robotics and Automation: Robotic systems are utilized for tasks like precision assembly, quality control, and even surgical procedures. Robots can enhance the consistency and accuracy of manufacturing processes while reducing the risk of errors.

Advanced Materials: The development of new materials, such as biodegradable polymers and smart materials that respond to external stimuli, has expanded the possibilities for creating innovative medical devices with enhanced functionalities.

Future:

Looking ahead, the future of precision manufacturing in the medical device industry holds even more exciting possibilities:

Nanotechnology: Nanoscale manufacturing techniques could enable the creation of devices with unprecedented precision and capabilities. Nanomaterials and nanoscale structures could be integrated into medical devices for improved sensing, drug delivery, and tissue regeneration.

Biofabrication: The field of biofabrication aims to create living tissues and organs through additive manufacturing techniques. This could revolutionize organ transplantation and tissue engineering, ultimately saving lives.

Artificial Intelligence (AI) and Machine Learning: AI could optimize manufacturing processes, predict maintenance needs, and enhance product quality. In combination with real-time monitoring, AI can ensure consistent and high-quality production.

Personalized Medicine: Precision manufacturing will likely continue to support the growth of personalized medicine. Devices tailored to individual patients' needs could become more common, leading to improved treatment outcomes.

Remote Manufacturing and Telemedicine: Advances in manufacturing and communication technology could lead to the remote creation and customization of medical devices, particularly in underserved areas or during emergencies.

Precision Manufacturing Processes in the Medical Device Industry

Precision manufacturing processes in the medical device industry are crucial for producing high-quality, reliable, and safe devices that meet stringent regulatory standards. These processes involve various techniques that ensure tight tolerances, accurate dimensions, and optimal performance.

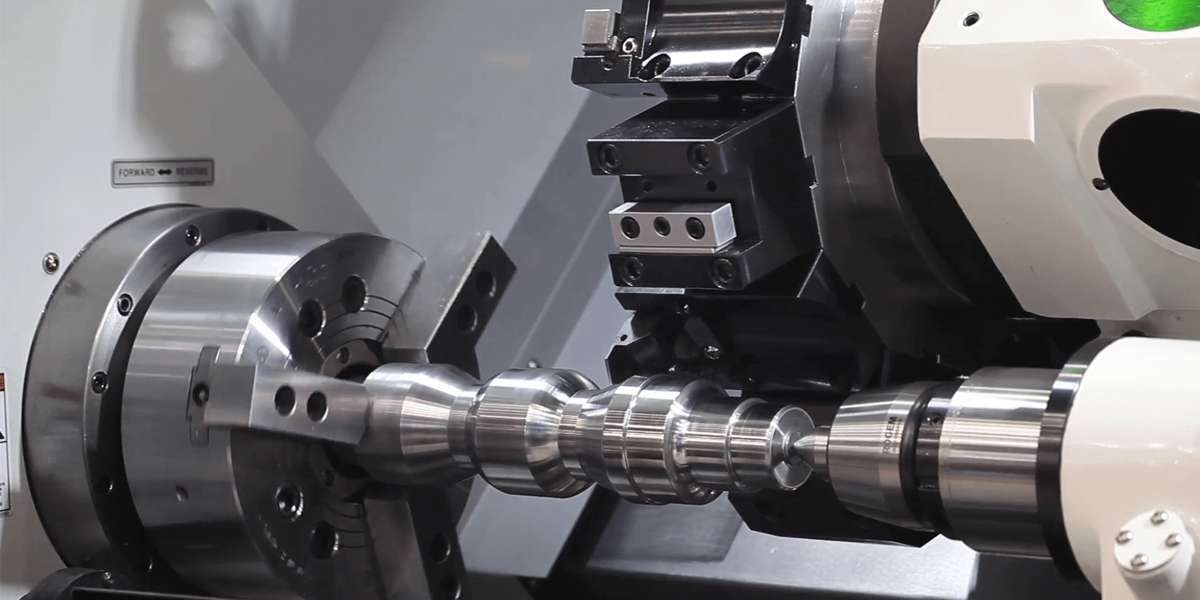

CNC Machining (Computer Numerical Control):

CNC machining involves using computer-controlled machines to precisely remove material from a workpiece. This process is used to create complex shapes and intricate features in medical devices, such as surgical instruments, orthopedic implants, and components for diagnostic equipment. CNC machining ensures high accuracy and repeatability.

Additive Manufacturing (3D Printing):

Additive manufacturing, commonly known as 3D printing, builds objects layer by layer using materials like metals, plastics, and ceramics. In the medical device industry, 3D printing is used to create patient-specific implants, prosthetics, surgical guides, and prototypes. Its design flexibility allows for complex geometries that would be difficult to achieve with traditional manufacturing methods.

Laser cutting and welding use focused laser beams to cut or join materials with high precision. In medical device manufacturing, laser cutting is often used to create intricate patterns in stents, catheters, and other devices. Laser welding is utilized for joining small components without causing excessive heat damage.

Microfabrication:

Microfabrication involves creating extremely small structures and components at the microscale level. This process is vital for producing microfluidic devices, sensors, and other miniaturized medical devices. Microfabrication techniques include photolithography, chemical etching, and micro-molding.

Electrodischarge Machining (EDM):

EDM is a non-contact machining process that uses electrical discharges to remove material from a workpiece. It is used for creating highly precise and intricate shapes in hard materials, such as titanium and steel, for medical devices like implants and surgical tools.

Swiss Machining:

Swiss machining, also known as Swiss-style turning, is used to produce small, high-precision components with tight tolerances. This process is particularly suitable for medical device components like screws, pins, and other intricate parts.

Grinding and Polishing:

Grinding and polishing processes are employed to achieve tight tolerances, smooth surfaces, and precise dimensions on medical devices. These processes are commonly used for implants, bone screws, and surgical instruments.

Injection molding is used to produce plastic components with high precision and consistency. Medical devices such as syringes, tubing, and connectors often use injection molding to achieve the required accuracy and quality.

Coating and Surface Treatments:

Coatings and surface treatments are applied to medical devices to enhance their functionality, biocompatibility, and durability. Techniques like plasma spraying, ion implantation, and chemical vapor deposition are used to deposit coatings on implants and other devices.

Precision manufacturing processes in the medical device industry are used to create various parts and components that are essential for medical devices.

Implants: Precision manufacturing processes are used to create implants such as orthopedic implants (like hip and knee implants), dental implants, spinal implants, and cardiovascular implants (like stents and pacemaker leads). These implants require high accuracy and biocompatibility to ensure successful integration into the patient's body.

Surgical Instruments: Precision manufacturing is crucial for producing surgical instruments like scalpels, forceps, scissors, and retractors. These instruments need to be precisely designed and manufactured to ensure optimal performance during medical procedures.

Prosthetics: Customized prosthetic devices, such as limbs, joints, and hearing aids, are often manufactured using precision techniques like 3D printing and CNC machining. These processes allow for personalized design and accurate fitting.

Microfluidic Devices: Precision manufacturing processes are used to create microfluidic devices for diagnostics, drug delivery, and lab-on-a-chip applications. These devices manipulate tiny amounts of fluids and are often used for point-of-care testing and medical research.

Catheters and Tubing: Catheters and tubing for various medical applications, such as angioplasty, infusion, and drainage, are manufactured using precision processes like extrusion, injection molding, and laser welding.

Electromechanical Components: Precision manufacturing is employed to create electromechanical components found in medical devices like pumps, motors, sensors, and connectors. These components are critical for devices like infusion pumps, imaging systems, and diagnostic equipment.

Microsensors: Miniaturized sensors for monitoring various physiological parameters, such as blood glucose levels or oxygen saturation, are created using microfabrication techniques. These sensors are integrated into wearable medical devices for continuous monitoring.

Stents: Precision manufacturing processes, including laser cutting and electrodischarge machining, are used to create coronary and vascular stents. These devices are inserted into blood vessels to maintain their patency and treat conditions like coronary artery disease.

Orthopedic Screws and Pins: Precision machining processes are used to create orthopedic screws, pins, and plates used in fracture fixation and orthopedic surgeries. These components need to be precisely manufactured to provide stability and support to fractured bones.

Diagnostics and Imaging Components: Precision manufacturing is used to create components for diagnostic devices like X-ray machines, MRI scanners, and ultrasound transducers. These components ensure accurate imaging and reliable diagnostic results.

Disposable Medical Components: Precision manufacturing techniques are also applied to create disposable components like syringes, IV connectors, and wound closure devices. These components need to meet strict quality and safety standards.

Biodegradable Implants: With advancements in materials science, precision manufacturing is used to create biodegradable implants that gradually break down within the body. These implants can be used for drug delivery, tissue regeneration, and temporary support.

Benefits and Enhancements of Precision Manufacturing for Medical Devices

Improved Accuracy and Quality: Precision manufacturing techniques ensure that medical devices are manufactured with extremely tight tolerances and high accuracy. This results in devices that perform reliably and consistently, reducing the risk of errors during medical procedures.

Customization and Personalization: Precision manufacturing enables the creation of patient-specific medical devices. Whether it's a custom-fit implant or a personalized prosthetic, these devices enhance patient comfort, functionality, and overall treatment success.

Complex Geometries: Techniques like 3D printing allow for the fabrication of intricate and complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for device designs and functionalities.

Reduced Material Waste: Precision manufacturing processes are often additive in nature, meaning they build up components layer by layer. This reduces material waste compared to subtractive methods like machining, making the manufacturing process more environmentally friendly.

Faster Prototyping: Precision manufacturing accelerates the prototyping phase of device development. With techniques like 3D printing, designers can quickly create prototypes to test and refine their ideas before moving to full-scale production.

Shorter Lead Times: Precision manufacturing allows for quicker turnaround times from design to production. This is especially valuable for medical devices needed urgently or in limited quantities.

Cost-Efficiency: Although precision manufacturing may have higher upfront costs due to technology and equipment, it can be cost-effective in the long run. It reduces the need for extensive post-processing and manual labor, leading to streamlined production.

Enhanced Biocompatibility: Precision manufacturing processes allow for the use of biocompatible materials that are safe for use in the human body. This is critical for medical devices that come into direct contact with bodily tissues or fluids.

Innovative Materials: Precision manufacturing enables the use of innovative materials, including biodegradable polymers, shape-memory alloys, and smart materials that respond to external stimuli. These materials can add advanced functionalities to medical devices.

Reduced Risk of Contamination: Precision manufacturing processes can be conducted in controlled environments, minimizing the risk of contamination and ensuring the sterility of medical devices. This is crucial for devices used in surgical procedures or implantation.

Advancements in Minimally Invasive Procedures: Precision manufacturing contributes to the development of smaller and more precise medical devices used in minimally invasive surgeries. This leads to shorter recovery times, less scarring, and reduced patient discomfort.

Remote Manufacturing and Telemedicine: Precision manufacturing enables the remote creation of medical devices, which can be particularly beneficial in remote or underserved areas. Telemedicine can be enhanced with the rapid production of devices tailored to patient needs.

Research and Development: Precision manufacturing facilitates the creation of prototypes and experimental devices for research and development purposes, enabling scientists and engineers to innovate and push the boundaries of medical technology.

The Importance of Precision Manufacturing to the Medical Device Industry

Precision manufacturing plays a crucial and transformative role in the medical device industry, offering a multitude of benefits that are essential for the development, production, and utilization of high-quality medical devices.

Patient Safety and Quality Assurance: Precision manufacturing ensures that medical devices are manufactured with the highest level of accuracy, consistency, and quality. This is vital for patient safety, as any errors or inconsistencies in medical devices could lead to adverse health outcomes.

Customization and Personalization: Precision manufacturing techniques, such as 3D printing and CNC machining, allow for the creation of customized and patient-specific medical devices. This tailoring improves the fit, comfort, and effectiveness of devices, leading to better patient outcomes.

Complex Device Designs: Precision manufacturing enables the creation of intricate and complex device designs that were previously unattainable. This has led to the development of advanced implants, microscale medical devices, and surgical instruments with enhanced functionalities.

Minimally Invasive Procedures: Precision manufacturing has revolutionized minimally invasive procedures by producing smaller, more precise devices. This reduces patient trauma, shortens recovery times, and enhances the overall patient experience.

Innovation and Research: Precision manufacturing facilitates rapid prototyping, iteration, and experimentation, enabling researchers and engineers to explore new device designs and functionalities. This drives innovation and pushes the boundaries of medical technology.

Advanced Materials and Functionalities: Precision manufacturing allows for the use of advanced materials and functional coatings that enhance the performance and biocompatibility of medical devices. This opens up opportunities for targeted drug delivery, smart devices, and more.

Efficiency and Cost-Effectiveness: Although precision manufacturing may have higher initial setup costs, it often leads to cost savings in the long run. Automated processes, reduced material waste, and streamlined production contribute to overall efficiency.

Telemedicine and Remote Manufacturing: Precision manufacturing supports remote manufacturing and customization, enabling the production of medical devices tailored to patient needs, especially in remote or underserved areas.

Biomedical Research and Collaboration: Precision manufacturing encourages collaboration between researchers, clinicians, and manufacturers. This fosters a multidisciplinary approach that leads to breakthroughs in medical device technology and patient care.

Medical Device Lifecycle Management: Precision manufacturing allows for more accurate tracking, monitoring, and maintenance of medical devices throughout their lifecycle. This ensures that devices continue to perform effectively and safely over time.

Sustainability: Precision manufacturing processes generate less material waste compared to traditional methods, contributing to a more environmentally sustainable production process.

Global Healthcare Access: Precision manufacturing can play a role in expanding access to high-quality medical devices, especially in regions with limited healthcare infrastructure. Remote production and customization can bridge gaps in healthcare delivery.

Emerging Healthcare Trends: Precision manufacturing aligns with emerging trends in healthcare, such as personalized medicine, telemedicine, and remote patient monitoring, enabling the development of devices that align with these trends.