About the Aerospace Industry

The aerospace industry is a broad and complex field that encompasses the development, manufacturing, and operation of aircraft, spacecraft, and related systems. It plays a crucial role in advancing technology, expanding human knowledge, and connecting people and goods across the globe.

Include:

Aircraft Industry: This segment includes the design, manufacturing, and maintenance of various types of aircraft, such as commercial airliners, military aircraft, helicopters, and general aviation planes.

Spacecraft Industry: This segment focuses on the design, construction, and operation of vehicles intended for space exploration, communication, scientific research, and satellite deployment.

Innovation and Technology:

The aerospace industry is characterized by continuous technological advancements. Innovations include more fuel-efficient engines, lightweight materials like composites, advanced avionics systems, and autonomous flight capabilities.

Space exploration has led to the development of technologies such as satellite-based navigation (GPS), weather forecasting, Earth observation, and interplanetary exploration.

Challenges:

High Costs: Developing and manufacturing aerospace technologies is capital-intensive and requires significant investments.

Safety and Regulation: The industry is heavily regulated due to safety concerns, especially in aviation, where rigorous standards must be met.

Environmental Impact: The aerospace industry contributes to carbon emissions due to fuel consumption, prompting efforts to develop more sustainable propulsion technologies.

Technical Complexity: Aerospace projects involve intricate engineering challenges and require interdisciplinary collaboration.

Market Demand:

The demand for commercial air travel has been steadily increasing due to factors like globalization, economic growth, and rising middle-class populations in emerging markets.

The space sector has also gained momentum with increased satellite launches, space tourism aspirations, and plans for Mars and lunar exploration.

International Collaboration:

Aerospace projects often involve collaboration between multiple countries and organizations. Space missions, for instance, frequently include contributions from international partners to share expertise and resources.

Future Trends:

Electric and hybrid-electric propulsion systems are being explored for both aircraft and spacecraft to reduce emissions and improve efficiency.

Reusability is a growing trend, with companies like SpaceX successfully landing and reusing rocket stages.

Advancements in materials science are leading to the development of stronger and lighter materials for improved performance.

What is Precision Manufacturing?

Precision manufacturing, also known as precision machining or precision engineering, refers to a manufacturing process that produces highly accurate and intricate components and products with tight tolerances and exceptional quality. This approach emphasizes the use of advanced technologies, tools, and techniques to create parts that meet exact specifications and precise measurements. Precision manufacturing is crucial in industries where small variations in dimensions can significantly impact the functionality and performance of the final product.

Key characteristics and aspects of precision manufacturing include:

Tight Tolerances: Precision manufacturing involves working with extremely small margins of error. The tolerances, or permissible deviations from specified dimensions, are often measured in micrometers or even nanometers.

Advanced Machinery: Precision machining relies on state-of-the-art machine tools, such as CNC (Computer Numerical Control) machines, which can execute highly complex operations with great accuracy. These machines are programmed to follow precise instructions to achieve the desired outcome.

High-Quality Materials: Precision manufacturing often utilizes high-quality materials that provide consistent properties and dimensions. These materials ensure that the final products meet the required specifications.

Skillful Workforce: Skilled technicians and engineers play a vital role in precision manufacturing. Their expertise is required to program CNC machines, set up tooling, monitor processes, and ensure quality control throughout the production cycle.

CAD/CAM Integration: Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are essential for designing intricate components and translating those designs into machine instructions. CAD/CAM integration ensures accuracy and consistency.

Quality Control: Rigorous quality control measures are integral to precision manufacturing. Inspection techniques like Coordinate Measuring Machines (CMMs) and optical measuring systems are used to verify that produced parts meet specifications.

Applications:

Aerospace: Precision manufacturing is crucial for producing aircraft components, where safety and reliability are paramount.

Medical Devices: Medical equipment and implants require precision manufacturing to ensure compatibility and functionality.

Electronics: Precision machining is used to create intricate components for electronics, such as microchips and circuit boards.

Automotive: Engine components, transmission parts, and other critical automotive parts often require precision manufacturing.

Optics: Lenses, mirrors, and other optical components demand high precision to achieve desired optical properties.

Advantages:

Improved Performance: Components made through precision manufacturing have consistent dimensions, leading to enhanced product performance and reliability.

Cost Savings: Precision manufacturing reduces waste, as there is less need for rework due to dimensional inaccuracies.

Innovation: Precision manufacturing enables the creation of intricate and complex designs that were previously not feasible.

Importance of precision manufacturing for aerospace

Precision manufacturing plays a crucial role in the aerospace industry due to the high demands for safety, reliability, and performance in aircraft and spacecraft.

Safety and Reliability: Aircraft and spacecraft operate in challenging and sometimes extreme conditions. Components manufactured with precision are less likely to fail or malfunction, which is critical for ensuring the safety of passengers, crew, and valuable payloads.

Tight Tolerances: Aerospace components require extremely tight tolerances to ensure proper fit, alignment, and functionality. Small deviations can lead to reduced efficiency, increased wear and tear, and potential system failures.

Weight Reduction: Aerospace manufacturers constantly seek to reduce the weight of aircraft and spacecraft to improve fuel efficiency and performance. Precision manufacturing allows for the use of lightweight materials and the removal of excess material without compromising structural integrity.

Aerodynamics and Efficiency: Precision manufacturing ensures that aircraft components, such as wings, fuselage sections, and engine parts, are manufactured to exact specifications. This contributes to optimal aerodynamics and overall efficiency, resulting in reduced fuel consumption and improved range.

Advanced Materials: The aerospace industry is always exploring new materials with superior properties. Precision manufacturing is necessary to work with these advanced materials while maintaining their desired characteristics.

Complex Geometry: Many aerospace components have intricate and complex geometries that cannot be easily achieved through traditional manufacturing methods. Precision machining allows for the creation of such complex shapes with high accuracy.

Engine Components: Aircraft engines, whether jet or turbine-based, require precision-manufactured components for optimal performance and fuel efficiency. Even small deviations in components like turbine blades can lead to reduced engine efficiency.

Space Exploration: Components used in spacecraft, satellites, and rovers need to withstand the harsh conditions of space and operate reliably over long periods.

In-Flight and In-Space Conditions: Aerospace components must perform consistently under various conditions, including temperature extremes, pressure changes, and vibration. Precision manufacturing ensures that components can withstand these challenges.

Reduced Maintenance: Components manufactured with precision are less likely to wear out quickly or require frequent maintenance. This reduces downtime and maintenance costs for aerospace operators.

Regulatory Compliance: Aerospace components are subject to stringent regulatory standards and certifications. Precision manufacturing helps ensure that components meet these standards and pass necessary inspections.

Innovation and Research: Precision manufacturing enables the development and testing of new aerospace technologies. Innovations in materials, design, and manufacturing processes are essential for advancing the industry.

Precision manufacturing processes in the aerospace industry involve various techniques and technologies that produce highly accurate and intricate components. These processes are used to create a wide range of aerospace components, from engine parts to structural elements. ponents produced using these processes:

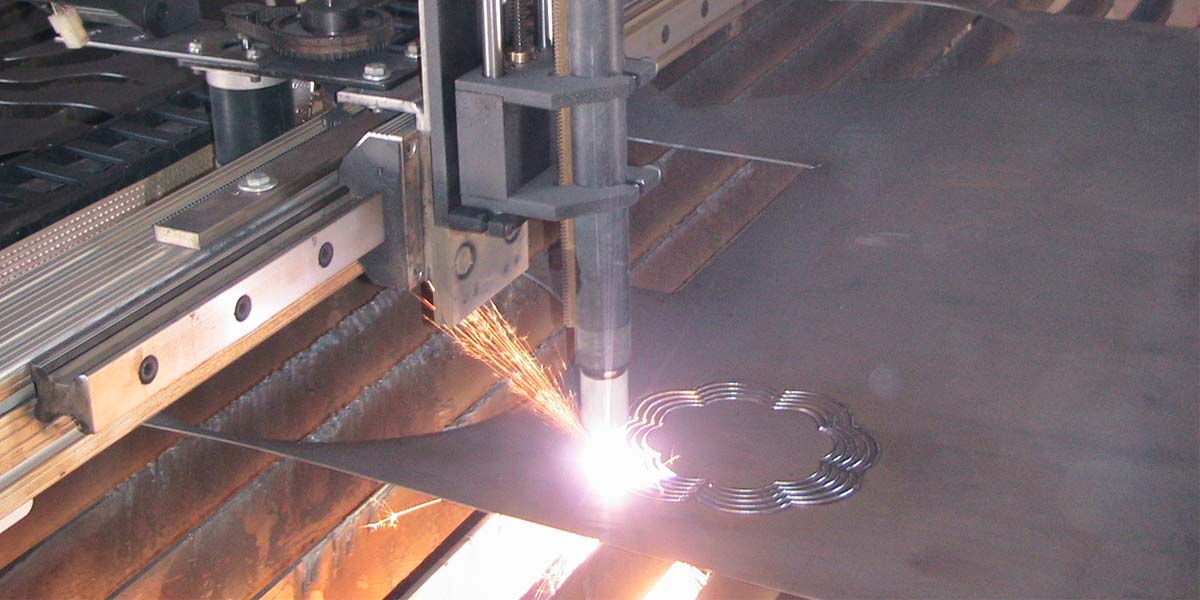

CNC Machining (Computer Numerical Control):

Components Produced: CNC machining is used to create a wide range of aerospace components, including engine parts (turbine blades, compressor disks), structural elements (frame members, brackets), and avionics housings.

Materials: Metals (aluminum, titanium, stainless steel), composites, and some engineering plastics.

EDM (Electrical Discharge Machining):

Components Produced: EDM is used for creating complex shapes, such as intricate turbine blade geometries, cooling holes, and fine features on aerospace components.

Materials: Hard metals, superalloys, and other conductive materials.

Components Produced: Laser cutting is used to produce precision-cut sheet metal parts for aircraft structures, while laser welding is used for joining components like fuselage sections and engine parts.

Materials: Metals (aluminum, titanium, stainless steel).

3D Printing (Additive Manufacturing):

Components Produced: Additive manufacturing is used for producing complex and lightweight parts, such as aerospace engine components, brackets, and prototypes.

Materials: Metals (titanium, aluminum, nickel-based alloys), thermoplastics, and composite materials.

Grinding and Finishing:

Components Produced: Precision grinding and finishing are used to achieve tight tolerances and surface finishes on components like gears, bearings, and precision shafts.

Materials: Metals (steel, titanium, alloys).

Swiss Machining:

Components Produced: Swiss machining is used for producing small, high-precision components like screws, pins, and connectors used in avionics and instrumentations.

Materials: Metals (stainless steel, brass, aluminum).

Electrochemical Machining (ECM):

Components Produced: ECM is used to create intricate shapes, fine features, and contours on aerospace components, particularly those made of high-strength alloys.

Materials: Metals (aluminum, titanium, superalloys).

Sheet Metal Forming:

Components Produced: Sheet metal forming processes such as hydroforming and stretch forming are used to produce aircraft structural components like panels, skin sections, and wing ribs.

Materials: Metals (aluminum, titanium, steel).

Components Produced: Investment casting is used to produce complex shapes for aerospace components like turbine blades, impellers, and engine casings.

Materials: Metals (nickel-based alloys, superalloys).

Composite Manufacturing:

Components Produced: Composite manufacturing techniques involve creating lightweight and strong composite materials for aircraft and spacecraft structures, wings, and other components.

Materials: Composite materials (fiber-reinforced polymers, carbon fiber composites).

The Past and Future of Precision Manufacturing in the Aerospace Industry

Past of Precision Manufacturing in the Aerospace Industry:

Early Precision Techniques: The aerospace industry has a long history of using precision techniques, even before the advent of advanced technologies. Skilled craftsmen and machinists were responsible for producing accurate and intricate components manually.

Manual Machining: In the early days of aviation, components were machined manually using basic tools. Precision craftsmanship was essential to ensure that parts fit together accurately and performed reliably.

Emergence of CNC: The introduction of Computer Numerical Control (CNC) machining in the mid-20th century revolutionized aerospace manufacturing. CNC machines allowed for automated and precise control of machining processes, leading to improved accuracy and repeatability.

Advancements in Materials: As aerospace materials evolved, precision manufacturing had to adapt. The development of high-strength alloys, composite materials, and superalloys required specialized precision machining techniques to handle these materials effectively.

Space Race and Technological Progress: The space race in the mid-20th century drove rapid advancements in precision manufacturing. The need to build reliable and precise spacecraft components spurred the development of new technologies and processes.

Future of Precision Manufacturing in the Aerospace Industry:

Additive Manufacturing (3D Printing): Additive manufacturing is expected to play an increasingly important role in aerospace. It enables the production of complex geometries, reduces material waste, and offers the potential for lightweight designs. Components like engine parts and structural elements can be created more efficiently.

Advanced Materials: As aerospace materials continue to advance, precision manufacturing processes will need to accommodate these materials. Techniques that can handle high-strength alloys, composite materials, and new hybrid materials will become essential.

Digital Twin Technology: Precision manufacturing is becoming more integrated with digital twin technology. Virtual models of components and systems can be tested and optimized before physical manufacturing, reducing development time and costs.

Automation and Robotics: Automation and robotics will continue to play a significant role in precision manufacturing. Collaborative robots (cobots) and advanced automation systems can improve efficiency and consistency in manufacturing processes.

Machine Learning and AI: Machine learning and artificial intelligence are being applied to optimize manufacturing processes, predict defects, and enhance quality control. These technologies can identify patterns and make real-time adjustments for better outcomes.

Sustainability: Precision manufacturing is likely to focus on sustainable practices, such as reducing energy consumption, minimizing waste, and exploring eco-friendly materials. This aligns with the aerospace industry's efforts to reduce its environmental footprint.

Choosing GD-HUB as an important partner in carrying out your aerospace program.