What is Green Energy?

Green energy refers to energy produced from renewable sources that have minimal impact on the environment. These sources are sustainable and generate electricity without depleting finite resources or causing significant environmental harm.

The green energy industry, also known as the renewable energy industry, encompasses various sectors that focus on producing energy from environmentally friendly and sustainable sources.

Key types of green energy include:

(1) Solar Energy: Involves capturing the sun's energy using photovoltaic cells to generate electricity.

(2) Wind Energy: Utilizes the kinetic energy of the wind to turn turbines and produce electricity.

(3) Hydropower: Generates electricity by harnessing the energy of flowing or falling water to turn turbines.

(4) Bioenergy: Involves the use of organic materials, such as plants and agricultural residues, to produce biofuels or generate heat and electricity.

(5) Geothermal Energy: Taps into the Earth's internal heat to produce steam, which drives turbines for electricity generation.

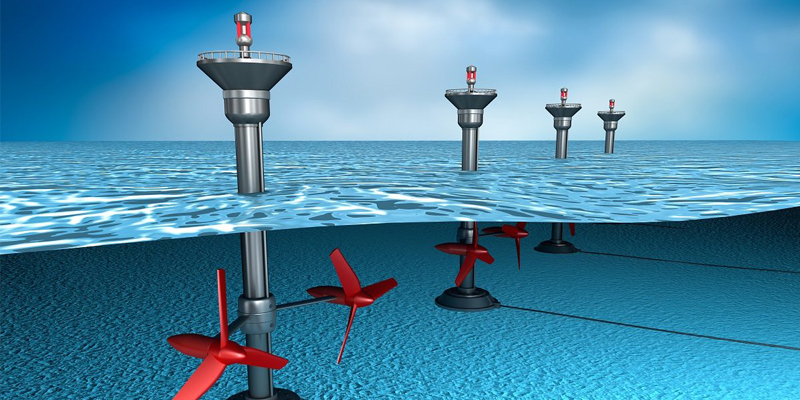

(6) Tidal and Wave Energy: Captures energy from the movement of tides or waves to generate electricity.

(7) Energy Storage: Involves technologies like batteries to store energy from renewable sources for later use, addressing intermittency.

The green energy industry plays a crucial role in transitioning away from fossil fuels, reducing carbon emissions, and promoting a more sustainable and environmentally friendly approach to meeting our energy needs. It's a rapidly evolving field with ongoing advancements in technology and a growing global emphasis on clean and renewable energy sources.

These sources are considered "green" because they produce minimal or no greenhouse gas emissions during electricity generation, unlike traditional fossil fuels such as coal, oil, and natural gas. Green energy plays a crucial role in mitigating climate change, reducing air pollution, and promoting sustainable development.

The adoption of green energy is a key component of global efforts to transition to a more sustainable and environmentally friendly energy system. As technology advances and economies scale up their use of renewable resources, green energy is becoming an increasingly important part of the global energy mix.

Why green energy need precision manufacturing?

The Importance of Precision Manufacturers in the Green Energy Industry:

(1) Efficiency and Performance:

Components manufactured with precision are more likely to meet exact specifications, leading to enhanced efficiency and performance of renewable energy systems. This is critical for maximizing energy output and optimizing the overall efficiency of green energy technologies.

(2) Tolerance Requirements:

Many components in renewable energy systems have strict tolerance requirements. Precision manufacturing ensures that components fit together seamlessly and operate within specified tolerances. For example, turbine blades in wind energy systems must be precisely manufactured to maintain balance and aerodynamic efficiency.

(3) Reliability and Durability:

Precision manufacturing contributes to the reliability and durability of components. Renewable energy systems often operate in challenging environments, and components must withstand various stresses. Precision manufacturing helps produce robust and long-lasting components that can endure harsh conditions.

(4) Customization and Innovation:

Precision manufacturing allows for customization and innovation in the design of green energy components. This is particularly important as the industry evolves, and there is a need for new, optimized designs. Precision processes such as 3D printing enable the creation of complex and customized components.

(5) Material Efficiency:

Precision manufacturing techniques enable the efficient use of materials, reducing waste and environmental impact. This aligns with the sustainable and eco-friendly goals of the green energy industry.

(6) Cost-Effectiveness:

While precision manufacturing may involve initial investments, it can lead to cost savings over the long term. High-precision components often result in fewer defects, less rework, and lower maintenance costs, contributing to the overall cost-effectiveness of renewable energy systems.

(7) Integration with Advanced Technologies:

Precision manufacturing processes, such as CNC machining and 3D printing, can integrate with advanced technologies like automation and digital manufacturing. This integration improves production speed, accuracy, and adaptability, keeping pace with the evolving needs of the green energy sector.

The precision manufacturing is a key enabler for the green energy industry, ensuring that components meet the high standards required for efficiency, reliability, and sustainability. It plays a vital role in advancing technology, reducing environmental impact, and driving the success of renewable energy initiatives.

How does GD-HUB's precision manufacturing meet the needs of the Green Energy Industry?

GD-HUB stands at the forefront of meeting the distinctive requirements of the Green Energy Industry through our precision manufacturing expertise. We offer the following range of services to meet the diverse needs of sustainable technologies:

High-Precision CNC Machining Services: Precision is key in the green energy sector, especially for components like gears and turbine blades. High-precision CNC machining ensures tight tolerances, contributing to the efficiency of systems.

Extrusion Services, Injection Molding Services, Overmolding Services, and Insert Molding Services: These services are vital for producing custom components for solar panels, wind turbine parts, and other renewable energy systems. The ability to mold intricate shapes and integrate various materials is essential for innovative designs.

Vacuum Casting Services: Ideal for small-scale production of high-quality prototypes and functional components, vacuum casting is valuable for testing and refining designs in the development of green energy technologies.

Die Casting Services: This process is well-suited for mass production of components with complex shapes, such as heat sinks for electronic components in renewable energy systems.

Rapid 3D Printing Services: Rapid prototyping is crucial for the iterative design process in the green energy industry. It allows for quick testing and modification of components before full-scale production.

Sheet Metal Fabrication Services: Sheet metal components are widely used in the construction of renewable energy systems. GD-HUB's fabrication services contribute to the production of durable and precise metal parts.

Surface Finishing Services: Enhancing the aesthetics and durability of components is essential. Surface finishing treatments improve corrosion resistance, reduce friction, and provide an overall polished appearance to components used in green energy systems.

Elevate your Green Energy project with GD-HUB's precision manufacturing prowess. From high-precision CNC machining to rapid 3D printing and surface finishing treatments, our comprehensive services are tailored to meet the exacting needs of the Green Energy Industry. Embark on the journey to advance your Green Energy Project with GD-HUB.