What types of metals are there?

Metals are a diverse group of elements that share certain common properties, such as good electrical and thermal conductivity, malleability, ductility, and a metallic luster.

Ferrous Metals: These metals contain iron as their primary constituent. The most common ferrous metals include:

Iron (Fe): Found in various forms, including cast iron, wrought iron, and steel.

Steel: An alloy of iron and carbon, often with other alloying elements like chromium, nickel, and manganese. There are various types of steel, such as carbon steel, stainless steel, and tool steel.

Cast Iron: A group of iron-carbon alloys with a high carbon content, making them brittle but good for casting.

Non-Ferrous Metals: These metals do not contain significant amounts of iron. Common non-ferrous metals include:

Aluminum (Al): Lightweight, corrosion-resistant, and widely used in various industries.

Copper (Cu): Known for its excellent electrical conductivity and used in electrical wiring, plumbing, and more.

Lead (Pb): Historically used in various applications, but its use has decreased due to environmental concerns.

Zinc (Zn): Often used as a protective coating for steel (galvanization) and in various alloys.

Nickel (Ni): Known for its corrosion resistance and use in stainless steel and nickel-based alloys.

Tin (Sn): Used to make solder and as a protective coating for other metals (tin plating).

Magnesium (Mg): Lightweight and used in aerospace and automotive industries.

Precious Metals: These metals are valued for their rarity and aesthetic appeal. Common precious metals include:

Gold (Au): Highly valued for jewelry, currency, and as an investment.

Silver (Ag): Used in jewelry, currency, and industrial applications like photography and electronics.

Platinum (Pt): Known for its durability and resistance to corrosion, often used in jewelry and catalytic converters.

Palladium (Pd): Used in catalytic converters, electronics, and jewelry.

Alloys: Many metals are combined with other elements to create alloys with specific properties. Some common metal alloys include:

Bronze: Copper combined with tin, often used for sculptures and musical instruments.

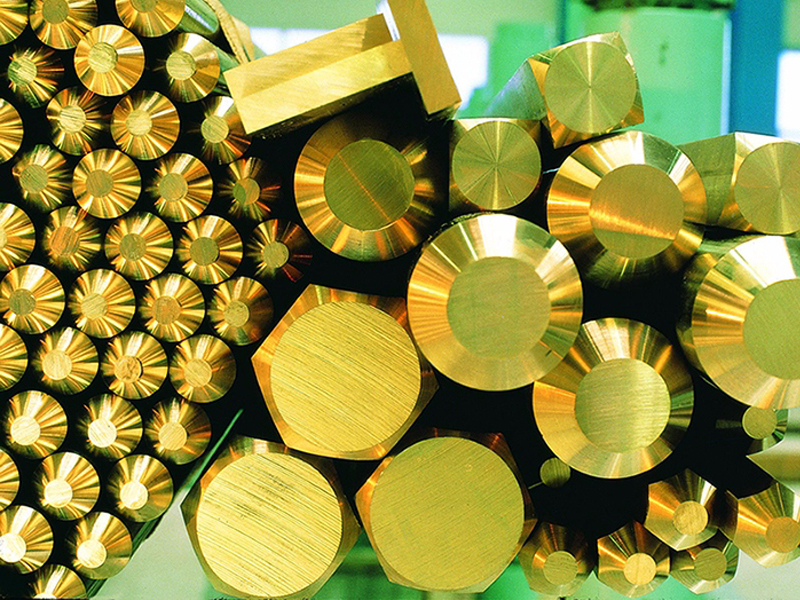

Brass: Copper combined with zinc, used in plumbing fixtures, musical instruments, and decorative items.

Stainless Steel: Iron combined with chromium and often nickel, known for its corrosion resistance.

Aluminum Alloys: Aluminum combined with various elements to enhance its strength, durability, and other properties.

Rare Earth Metals: A group of elements that includes scandium, yttrium, and the lanthanides. These metals are used in various high-tech applications like electronics and magnets.

Transitional Metals: Elements found in the middle of the periodic table, including titanium, iron, copper, and others. They often have a wide range of oxidation states and are used in diverse applications.

Heavy Metals: Metals with a high atomic number, often considered toxic in elevated concentrations. Examples include lead, mercury, and cadmium.

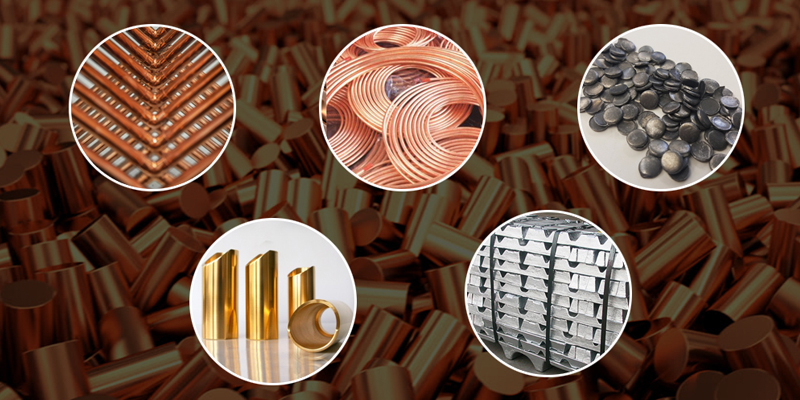

What is Non-Ferrous Metals

Non-ferrous metals are a category of metals that do not contain significant amounts of iron as their primary constituent. Unlike ferrous metals, which are mainly composed of iron, non-ferrous metals have different properties and applications.

Features of Non-Ferrous Metals:

Low Iron Content: Non-ferrous metals contain very little or no iron. The absence of iron gives them distinct properties, such as corrosion resistance and different mechanical characteristics compared to ferrous metals.

Corrosion Resistance: Many non-ferrous metals, such as aluminum, copper, and titanium, exhibit excellent resistance to corrosion, making them suitable for outdoor and marine applications.

Lightweight: Several non-ferrous metals, including aluminum and magnesium, are lightweight, which makes them ideal for aerospace, automotive, and transportation industries.

Good Electrical Conductivity: Non-ferrous metals like copper and silver are excellent conductors of electricity, making them essential for electrical wiring and electronic components.

Malleability and Ductility: Non-ferrous metals can be easily shaped and formed, allowing for a wide range of manufacturing processes, including forging, rolling, and extrusion.

High Melting Points: Some non-ferrous metals, such as tungsten, have very high melting points, making them suitable for high-temperature applications.

Examples of Non-Ferrous Metals:

Aluminum (Al): Lightweight and corrosion-resistant, aluminum is used in a wide range of applications, including aircraft construction, automotive parts, beverage cans, and building materials.

Copper (Cu): Known for its excellent electrical and thermal conductivity, copper is used in electrical wiring, plumbing, heat exchangers, and electronic components.

Brass: A copper-zinc alloy that is corrosion-resistant and has a yellowish color. Brass is used for decorative items, plumbing fittings, musical instruments, and more.

Bronze: An alloy of copper and tin (and sometimes other elements), bronze is known for its strength, corrosion resistance, and historical significance. It is used in sculptures, bearings, and musical instruments.

Lead (Pb): Although its use has declined due to health and environmental concerns, lead has historically been used in batteries, radiation shielding, and as a component in some alloys.

Zinc (Zn): Often used as a coating for steel (galvanization), zinc provides corrosion protection. It is also used in die-casting and as an alloying element.

Nickel (Ni): Nickel is used in various applications, including stainless steel production, electroplating, and as an alloying element in high-temperature materials.

Titanium (Ti): Known for its high strength-to-weight ratio and corrosion resistance, titanium is used in aerospace, medical implants, and sporting equipment.

Magnesium (Mg): Lightweight and strong, magnesium is used in aerospace, automotive parts, and portable electronic devices.

Tin (Sn): Tin is used to make solder, as a coating for other metals (tin plating), and in the production of various alloys.

There are some general processing characteristics that are often associated with non-ferrous metals:

Malleability and Ductility: Non-ferrous metals are typically malleable and ductile, which means they can be easily shaped and formed without cracking or breaking. This property makes them suitable for processes like forging, rolling, and extrusion to create a wide range of products.

Low Melting Points: Many non-ferrous metals have relatively low melting points compared to ferrous metals. This property allows for easier casting and welding processes. For example, aluminum and copper have relatively low melting points.

High Electrical Conductivity: Some non-ferrous metals, like copper and silver, have excellent electrical conductivity. This makes them ideal for electrical wiring, connectors, and electronic components.

Corrosion Resistance: Several non-ferrous metals, including aluminum, copper, and titanium, exhibit high resistance to corrosion. This makes them suitable for outdoor and marine applications where exposure to moisture and harsh environments is common.

Lightweight: Metals like aluminum and magnesium are lightweight, making them desirable for industries that require materials with a high strength-to-weight ratio, such as aerospace and automotive manufacturing.

Heat Resistance: Certain non-ferrous metals, like titanium, have excellent heat resistance, allowing them to withstand high temperatures without significant deformation or degradation. This property is valuable in aerospace and industrial applications.

Alloying: Non-ferrous metals are often alloyed with other elements to enhance their properties. Alloying can improve strength, hardness, corrosion resistance, and other characteristics. For example, brass is an alloy of copper and zinc, while bronze is an alloy of copper and tin.

Precision Machining: Non-ferrous metals are typically easier to machine compared to some ferrous metals like cast iron. This makes them suitable for precision machining processes, including milling, turning, and drilling.

Welding: Many non-ferrous metals can be welded successfully using various welding methods, including TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding. Proper welding techniques and filler materials specific to the metal being used are essential.

Surface Finishing: Non-ferrous metals are often chosen for their aesthetic appeal, and they can be polished, plated, anodized, or treated with various coatings to achieve specific surface finishes and appearances.

What precision manufacturing processes can they use?

Non-ferrous metals are commonly used in precision manufacturing processes due to their unique properties, including malleability, corrosion resistance, and excellent electrical conductivity.

Machining: Precision machining processes like turning, milling, drilling, and grinding are frequently used with non-ferrous metals. Copper, aluminum, and brass, among others, can be precisely shaped and dimensionally accurate using CNC (Computer Numerical Control) machines.

Electrical Discharge Machining (EDM): EDM is a precise manufacturing process that uses electrical discharges to remove material from a workpiece. It is commonly used with conductive materials like copper and graphite electrodes.

Wire EDM: Wire EDM is a variant of EDM that uses a thin wire electrode to cut intricate shapes in non-ferrous metals. It is often used in tool and die manufacturing and for creating complex parts with tight tolerances.

Waterjet Cutting: Waterjet cutting is suitable for cutting various non-ferrous metals, including aluminum, copper, and titanium, using a high-pressure jet of water mixed with abrasive particles. It provides precision and minimizes heat-affected zones.

Laser Cutting: Laser cutting is employed for high-precision cutting and engraving of non-ferrous metals like aluminum, brass, and copper. It allows for intricate designs and fine details.

Electrochemical Machining (ECM): ECM is a non-traditional machining process that can be used for precision shaping of non-ferrous metals. It is especially useful for materials that are difficult to machine by conventional means.

Chemical Etching: Chemical etching, or photochemical machining, is a process that uses chemical reactions to selectively remove material from the surface of non-ferrous metals. It is used for creating highly detailed, fine features in parts.

Die Casting: Non-ferrous metals, such as aluminum, magnesium, and zinc, are commonly used in die casting processes to create complex and precise metal components. Die casting offers high accuracy and repeatability.

Extrusion: Aluminum and other non-ferrous metals can be extruded to create intricate profiles and shapes with high precision. Extrusion is often used in the production of architectural and automotive components.

Precision Welding: Welding processes like TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding are used to join non-ferrous metal components with precision and control. These processes are commonly employed in aerospace, electronics, and automotive industries.

Anodizing: Anodizing is an electrochemical process that creates a protective and decorative oxide layer on the surface of aluminum. It can be precisely controlled to achieve specific colors and surface properties.

Surface Finishing: Non-ferrous metals are often used for their aesthetic qualities, and precision processes like polishing, electroplating, and coating are employed to achieve desired surface finishes and appearances.

These processes enable the production of precise and high-quality components used in various industries, including aerospace, electronics, automotive, and medical devices.

Applications for non-ferrous metals

Non-ferrous metals have a wide range of applications across various industries due to their unique properties, which include corrosion resistance, lightweight nature, excellent electrical conductivity, and malleability.

Electrical and Electronics:

Copper: Used in electrical wiring, conductors, bus bars, and printed circuit boards (PCBs) due to its high electrical conductivity.

Aluminum: Found in electrical transmission lines, heat sinks, and electronic housings due to its lightweight and good conductivity.

Silver: Used in electrical contacts and switches due to its high electrical conductivity and low contact resistance.

Aluminum: Widely used in aircraft construction due to its lightweight properties.

Titanium: Used in aircraft components, including airframes, engine parts, and landing gear, due to its strength-to-weight ratio and corrosion resistance.

Magnesium: Found in aircraft and aerospace applications due to its lightweight properties.

Aluminum: Used in engine blocks, wheels, and body panels to reduce weight and improve fuel efficiency.

Copper: Used in radiators and electrical systems.

Lead: Historically used in automotive batteries (though this use has declined due to environmental concerns).

Construction and Architecture:

Aluminum: Used in windows, doors, and structural components due to its corrosion resistance and lightweight properties.

Copper: Used in roofing, gutters, and decorative architectural elements.

Brass and Bronze: Used in architectural details, sculptures, and ornamental fixtures.

Marine and Shipbuilding:

Aluminum: Used in ship construction due to its corrosion resistance and lightweight nature.

Copper-Nickel Alloys: Used in pipes, fittings, and hulls due to their resistance to saltwater corrosion.

Titanium: Used in medical implants due to its biocompatibility and corrosion resistance.

Stainless Steel: Commonly used for surgical instruments and medical equipment due to its corrosion resistance and sterilizability.

Chemical and Food Processing:

Stainless Steel: Used in tanks, pipes, and equipment in corrosive environments due to its resistance to chemical reactions and ease of cleaning.

Consumer Goods:

Aluminum: Found in household items like cookware, beverage cans, and aluminum foil.

Copper: Used in plumbing fixtures, wiring, and decorative objects.

Silver: Used in jewelry, coins, and tableware.

Energy and Renewable Energy:

Copper: Used in electrical cables, wind turbine generators, and solar panels.

Aluminum: Used in electrical transmission lines and photovoltaic solar panels.

Defense and Military:

Aluminum and Titanium: Used in military aircraft, vehicles, and weaponry due to their strength-to-weight ratios and durability.

Copper and Brass: Used in ammunition and casings.

Transportation:

Aluminum: Used in trains, bicycles, and other modes of transportation to reduce weight and increase efficiency.

Sports and Recreation:

Magnesium and Aluminum Alloys: Used in the construction of lightweight bicycle frames, golf clubs, and sporting equipment.

Care is needed when processing non-ferrous metals:

Corrosion Sensitivity: Many non-ferrous metals, such as aluminum, copper, and brass, are susceptible to corrosion. To prevent corrosion during processing and subsequent use, it's essential to avoid contamination with ferrous materials and to store them in dry, non-corrosive environments.

Fire and Explosion Hazards: Some non-ferrous metal powders, such as aluminum and magnesium, can be highly flammable and pose fire and explosion risks when exposed to certain conditions. Safety measures, such as proper ventilation and fire prevention techniques, are crucial when working with these materials.

Dust and Fume Control: Metal dust and fumes generated during machining, cutting, or welding can be hazardous to health. Adequate dust and fume extraction systems and personal protective equipment (PPE) should be used to minimize exposure.

Protection from Oxidation: Non-ferrous metals can oxidize rapidly when exposed to air at elevated temperatures. To prevent this, shielding gases or coatings may be used during welding or heat treatment.

Toxic Fumes: Certain non-ferrous metals, such as zinc and cadmium, can release toxic fumes when heated or processed. Proper ventilation and the use of appropriate respiratory protection are essential when working with such materials.

Metal Allergies: Some individuals may have allergic reactions to certain non-ferrous metals like nickel. Skin contact should be minimized, and appropriate protective clothing should be worn when handling these metals.

Material Hardness: Non-ferrous metals can vary widely in terms of hardness and machinability. Proper cutting tools and machining parameters should be selected to ensure efficient and safe processing.

Exothermic Reactions: Some non-ferrous metals, like potassium and sodium, can react violently with water. These materials require special handling procedures to prevent accidents.

Electrical Conductivity: The high electrical conductivity of some non-ferrous metals, such as copper and aluminum, can pose electrical shock hazards. Proper insulation and safety protocols should be followed when working on electrical components.

Material Compatibility: Ensure that equipment and tools used in processing non-ferrous metals are compatible with the specific metal being processed to prevent contamination and adverse reactions.

Dust Explosions: Dust generated from non-ferrous metal processing can create explosive atmospheres. Implement safety measures to prevent dust explosions, such as proper dust collection and storage.

Personal Protective Equipment (PPE): Depending on the specific processes and materials used, appropriate PPE should be worn, including safety glasses, gloves, aprons, respirators, and ear protection.

Access to technical support on non-ferrous metals.