Surface finishing process can be divided into four aspects:

1, mechanical surface treatment: sandblasting, shot blasting, grinding, rolling, polishing, brushing, spraying, painting, wiping oil and so on;

2, chemical surface treatment: blue and black, phosphating, pickling, chemical plating of various metals and alloys, TD treatment, QPQ treatment, chemical oxidation and so on;

3、Electrochemical surface treatment: anodic oxidation, electrochemical polishing, electroplating and so on;

4, modern surface treatment: chemical vapor deposition CVD, physical vapor deposition PVD, ion implantation, ion plating, laser surface treatment and so on;

In this article we will discuss the modern surface treatment process.

What is Chemical Vapor Deposition CVD, Physical Vapor Deposition PVD, Ion Implantation, Ion Plating, Laser Surface Treatment?

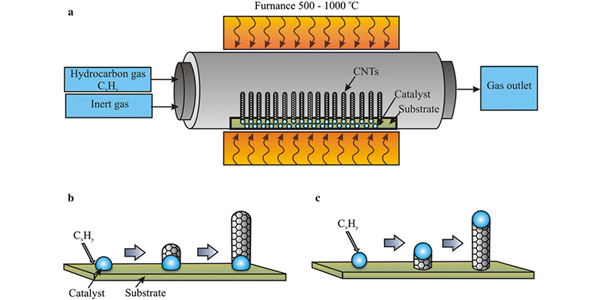

Chemical Vapor Deposition (CVD):

CVD is a process used to deposit thin films of material onto a substrate. It involves the chemical reaction of gaseous precursors to form a solid material on the substrate's surface. The precursors react in a controlled environment, typically at elevated temperatures. This process can be used to create coatings with precise control over thickness, composition, and properties. CVD is commonly used in semiconductor manufacturing, creating protective coatings, and producing materials like diamond films.

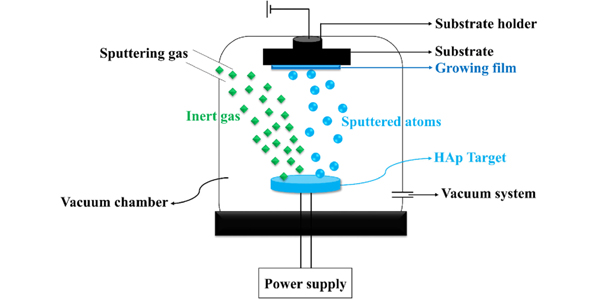

Physical Vapor Deposition (PVD):

PVD is a thin film deposition process where material is physically removed from a source (often in a vacuum chamber) and then deposited onto a substrate. This is usually done through methods like evaporation or sputtering. PVD coatings can provide improved hardness, wear resistance, and decorative finishes. Applications include producing coatings for tools, decorative items, and semiconductor devices.

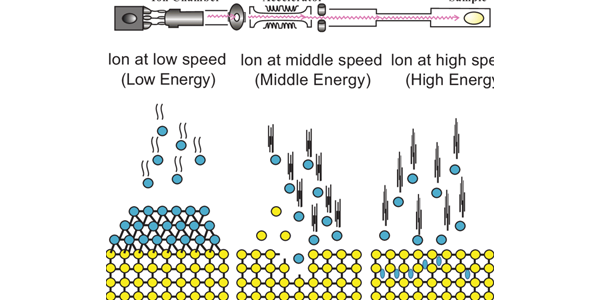

Ion Implantation:

Ion implantation involves bombarding a substrate with high-energy ions, typically from an ion beam accelerator. The ions penetrate the surface and become embedded in the material. This process can modify material properties such as hardness, conductivity, and corrosion resistance. It's often used in semiconductor manufacturing to introduce dopants that modify the electrical behavior of silicon wafers.

Ion Plating:

Ion plating is a variant of PVD where ionized vaporized material is accelerated towards the substrate. The ions enhance adhesion and surface properties of the deposited film. This process is used to create dense, high-adhesion coatings for various applications including optics, cutting tools, and decorative items.

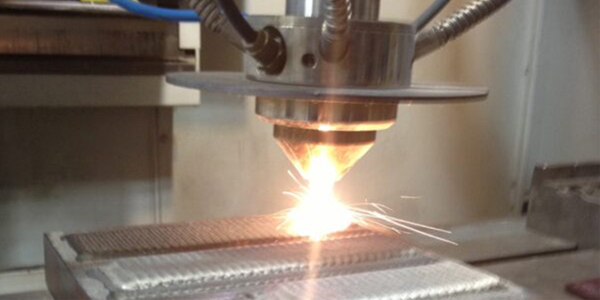

Laser Surface Treatment:

Laser surface treatment involves using a high-energy laser beam to modify the surface of a material. The laser's heat can melt, vaporize, or modify the material's structure, leading to changes in properties like hardness, wear resistance, and texture. Laser surface treatment is used to improve the performance of components like engine parts, molds, and cutting tools.

Role of chemical vapour deposition CVD, physical vapour deposition PVD, ion implantation, ion plating, laser surface treatment

Chemical Vapor Deposition (CVD):

Role: CVD is used to deposit thin films of material onto a substrate through chemical reactions in a gaseous environment. It is employed to create coatings with controlled thickness, composition, and properties.

Applications: CVD is essential in industries requiring precise thin films, such as semiconductor manufacturing, optics, protective coatings, and advanced materials synthesis.

Physical Vapor Deposition (PVD):

Role: PVD involves the physical deposition of material onto a substrate from a vaporized source. It's used to create thin films with tailored properties such as hardness, wear resistance, and decorative finishes.

Applications: PVD is utilized in industries needing coatings with enhanced properties, including automotive, tooling, electronics, and decorative items.

Ion Implantation:

Role: Ion implantation modifies material properties by introducing ions into the substrate. It's used to adjust conductivity, hardness, and other properties at controlled depths.

Applications: Ion implantation plays a crucial role in semiconductor manufacturing, where precise doping is required to create electronic devices with specific characteristics.

Ion Plating:

Role: Ion plating enhances the adhesion and properties of deposited coatings by introducing ionized vaporized material to the substrate. It's used to improve coating quality and performance.

Applications: Ion plating is applied in industries requiring durable, high-performance coatings, such as aerospace, automotive, and precision components.

Laser Surface Treatment:

Role: Laser surface treatment alters material properties by using high-energy laser beams. It can modify hardness, wear resistance, and other surface characteristics.

Applications: Laser surface treatment is used to improve performance and longevity of components in industries like automotive, aerospace, and medical devices.

Their benefit

Chemical Vapor Deposition (CVD) Benefit

Precise Control: CVD allows precise control over the composition and properties of the deposited thin films, making it suitable for applications with specific requirements.

Uniform Coatings: CVD can produce uniform coatings on complex-shaped substrates with consistent thickness and properties.

High Purity: CVD can create high-purity coatings, making it suitable for applications where contamination is a concern.

Diverse Applications: CVD is used in semiconductor manufacturing, protective coatings, and producing materials like diamond films for various applications.

Physical Vapor Deposition (PVD) Benefit:

Versatile Coating Properties: PVD coatings can be tailored to provide specific properties such as hardness, wear resistance, and low friction.

Thin Film Deposition: PVD creates thin films with excellent adhesion and uniform thickness, even on complex shapes.

Less Thermal Impact: PVD operates at lower temperatures compared to some other processes, reducing the risk of thermal damage to substrates.

Decorative Finishes: PVD is commonly used for creating decorative and functional coatings on items like jewelry, watches, and eyeglasses.

Ion Implantation Benefit:

Precise Doping: Ion implantation allows precise control over introducing specific elements into a material, modifying its electrical and mechanical properties.

Depth Control: The energy of the implanted ions determines their penetration depth, enabling precise control over the modification depth.

Selective Doping: Ion implantation can selectively modify certain areas of a material, making it suitable for semiconductor device fabrication and other applications requiring localized changes.

Ion Plating Benefit:

Enhanced Adhesion: Ion plating improves the adhesion of the deposited material to the substrate, resulting in more durable coatings.

Dense Coatings: The ionized vaporized material packs more densely onto the substrate, creating coatings with improved properties.

Increased Performance: Ion-plated coatings can enhance wear resistance, corrosion resistance, and other properties, making them valuable for various industrial applications.

Laser Surface Treatment Benefit:

Localized Treatment: Laser surface treatment allows precise treatment of specific areas without affecting the entire component, minimizing waste.

Tailored Properties: Laser treatment can selectively modify material properties like hardness and texture for specific functional requirements.

No Need for Additional Materials: Laser treatment doesn't require additional coatings or chemicals, reducing the need for external materials.

Reduced Distortion: Laser treatment generates minimal heat-affected zones, reducing the risk of distortion in treated components.

What are they application in which industries and material?

Chemical Vapor Deposition (CVD):

Industries: Semiconductor manufacturing, aerospace, automotive, electronics, cutting tools, optical coatings, and more.

Materials: CVD is used with a wide range of materials, including metals, ceramics, semiconductors, and even diamond films.

Physical Vapor Deposition (PVD):

Industries: Tooling, automotive, aerospace, decorative coatings, optics, electronics, medical devices, and more.

Materials: PVD is used with metals, alloys, ceramics, and some polymers to create coatings with various properties.

Ion Implantation:

Industries: Semiconductor fabrication, electronics, materials research, nuclear industry, medical devices, and more.

Materials: Ion implantation is commonly used with semiconductors like silicon and compound semiconductors, as well as metals, polymers, and ceramics.

Ion Plating:

Industries: Aerospace, automotive, cutting tools, decorative coatings, optics, electronics, and precision components.

Materials: Ion plating is used with metals and alloys to create coatings with enhanced properties.

Laser Surface Treatment:

Industries: Automotive, aerospace, tooling, electronics, medical devices, and more.

Materials: Laser surface treatment is applied to metals, alloys, ceramics, polymers, and composites for various improvements in surface properties.

Each technique has its specific strengths and is chosen based on the desired modifications, material characteristics, industry requirements, and cost-effectiveness.

Differences with electrochemical surface treatment: anodizing, electrochemical polishing, electroplating

Anodizing:

Process: Anodizing is an electrochemical process used primarily with aluminum and its alloys. It involves creating a controlled oxide layer on the surface of the metal by immersing it in an electrolyte and applying an electric current.

Purpose: Anodizing enhances corrosion resistance, improves wear resistance, and allows for coloring through various methods like dyeing or electrolytic coloring.

Applications: Anodizing is widely used in industries like aerospace, automotive, electronics, and architectural applications for both functional and decorative purposes.

Electrochemical Polishing:

Process: Electrochemical polishing is a process that removes material from the surface of a metal through controlled electrochemical dissolution. It is used to improve surface finish and remove imperfections.

Purpose: Electrochemical polishing produces a smooth and reflective surface, eliminating micro-roughness and scratches. It's often used to improve aesthetics and prepare surfaces for further treatments.

Applications: Industries such as electronics, medical devices, and precision engineering use electrochemical polishing to achieve high-quality, smooth surfaces on metal components.

Electroplating:

Process: Electroplating involves depositing a metal coating onto a substrate (cathode) by immersing it in an electrolyte solution and passing an electric current through it. The metal ions in the solution are reduced onto the substrate's surface.

Purpose: Electroplating enhances properties such as corrosion resistance, wear resistance, conductivity, and aesthetics. It can also provide functional characteristics like solderability.

Applications: Electroplating is used in various industries, including automotive, electronics, jewelry, and plumbing, to create coatings that offer specific properties and improve the appearance of parts.