Introduction:

In the realm of precision manufacturing, achieving top-tier results goes beyond the production phase—it extends to the critical step of metal surface finishing. From augmenting aesthetics to ensuring robust corrosion resistance, selecting the right metal finishing technique is paramount. In this comprehensive guide, we'll delve into various metal finishing methods and their applications, shedding light on the benefits and drawbacks of each.

Understanding the Significance of Metal Surface Finishing

Metal finishing is a diverse array of treatments, ranging from the artistry of polishing to processes that intricately affect a metal's molecular structure. This multifaceted approach not only improves the appearance of a component but also addresses the inherent drawbacks of specific metals.

Why Metal Finishing Matters in Precision Manufacturing?

While metals are incredibly versatile, individual metals possess unique drawbacks and benefits that cater them toward specific applications. Metal finishing becomes the bridge, enhancing electrical conductivity, durability, and chemical resistance. It transforms cost-effective metals into versatile solutions, making them suitable for a broader range of applications.

Key Considerations Of Metal Finishing Technique:

Before making critical manufacturing decisions, it is paramount to consider various factors such as:

Required Finish:

Understand the aesthetic and functional requirements of the finished product. Determine whether a high-polish, corrosion-resistant, textured, or colored finish is needed. Different finishing techniques excel in achieving specific finishes, so align the method with the desired outcome.

Base Metal:

Evaluate the material of the base metal. Certain finishing techniques are better suited for specific metals. For instance, electroplating may be ideal for enhancing the appearance of certain alloys, while anodizing is often used for aluminum. Consider the compatibility of the finishing method with the base material.

Time Constraints:

Assess the production timeline and delivery schedules. Some finishing techniques may be time-consuming, impacting overall lead times. For time-sensitive projects, choose a method that aligns with the required production schedules. Automated processes like powder coating might be more suitable for faster turnaround times.

Preparation Requirements:

Examine the level of preparation work required before applying the finish. Different techniques may demand specific surface preparation, such as cleaning, degreasing, or masking. Factor in the preparation steps and ensure they align with manufacturing capabilities and efficiency goals.

The chosen finishing technique significantly impacts costs, delivery schedules, and the efficiency of the supply chain.

Exploring Diverse Metal Finishing Techniques

Plating (or Conversion) Coatings

Electroplating: Involves immersing components in metal-ion baths for coating.

Electroless Plating: An autocatalytic process requiring no external power.

Anodizing

An electrochemical procedure that creates a long-lasting, attractive, and corrosion-resistant anodic oxide finish. It is commonly used for aluminum parts but is also effective on nonferrous metals such as magnesium and titanium.

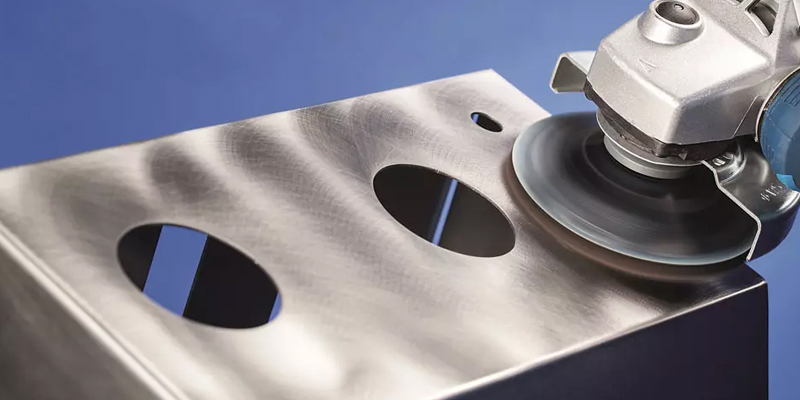

Metal Grinding

Utilizes grinding machines with abrasives to smooth out metal surfaces, reducing surface roughness.

Polishing/Buffing

Abrasive materials are employed to reduce the surface roughness of a metal alloy, improving both appearance and functionality.

Electropolishing

The inverse of electroplating, electropolishing removes metal ions from the surface, resulting in a polished and smooth finish.

Painting

Powder Coating: A modern electrostatic painting technique that efficiently covers metal parts.

Blasting

Abrasive blasting is commonly used for products that require a consistent matte texture.

Brushing

Similar to polishing, brushing produces a uniform surface texture, smoothing off a part's exterior.

Choosing the Best Finish for Metal: Tailoring Solutions

The ideal finishing technique depends on various factors such as specifications, the material used, and budget constraints. Galvanizing stands out for corrosion resistance, polishing for a high-quality aesthetic, and wet painting or powder coating for budget-friendly options.

Applications of Metal Finishing

Metal finishing is extensively used in the automotive sector to enhance the appearance and durability of components. From polished chrome parts to corrosion-resistant coatings, metal finishing contributes to both aesthetics and functionality.

Electronics and Electrical Components:

In electronics, particularly in circuit boards and connectors, metal finishing helps improve conductivity and resistance to corrosion. Precise finishes are crucial for ensuring the optimal performance of electrical components.

Metal finishing is vital in the aerospace industry for its ability to provide corrosion resistance and improve the aerodynamic properties of components. Anodizing, in particular, is commonly used for aluminum parts in aerospace applications.

The medical industry relies on metal finishing to ensure the cleanliness, corrosion resistance, and biocompatibility of medical devices. Electropolishing, for instance, is employed to create smooth and sanitary surfaces on surgical instruments.

Consumer Goods:

Products like household appliances, furniture, and jewelry benefit from metal finishing for aesthetic appeal and protection against corrosion. Polishing, plating, and powder coating are commonly used to achieve desired finishes in consumer goods.

Construction and Architecture:

Metal finishing is employed in the construction industry for architectural elements, structural components, and decorative features. Finishes like powder coating and anodizing help protect metal surfaces from harsh environmental conditions.

Oil and Gas Industry:

Metal finishing plays a crucial role in the oil and gas sector, where components are exposed to corrosive environments. Protective coatings, such as galvanizing, are applied to ensure the longevity and performance of metal parts.

Military and Defense:

In military applications, metal finishing is essential for enhancing the durability and functionality of equipment. Corrosion-resistant coatings and finishes contribute to the longevity of military hardware.

Machinery and Equipment:

Industrial machinery and equipment often undergo metal finishing to improve wear resistance, corrosion protection, and overall performance. Grinding, polishing, and coating processes are applied to achieve desired surface properties.

Telecommunications:

Metal finishing is integral in the manufacturing of telecommunications equipment, ensuring the longevity and reliability of components exposed to various environmental conditions.

Components used in power generation and distribution benefit from metal finishing to resist corrosion and maintain optimal performance. Surface treatments contribute to the longevity of equipment in power plants.

Renewable Energy:

In the renewable energy sector, components such as wind turbine parts and solar panels often undergo metal finishing to enhance resistance to environmental factors and improve overall efficiency.

Benefits & Drawbacks of Metal Finishing Techniques

Benefits of Metal Finishing Techniques:

Corrosion Resistance:

Benefit: Metal finishing provides a protective layer, such as through galvanizing or coatings, preventing corrosion and extending the lifespan of metal components.

Enhanced Aesthetics:

Benefit: Finishing techniques like polishing, painting, and plating improve the visual appeal of metal products, making them more attractive to consumers.

Improved Functionality:

Benefit: Certain finishing processes, such as anodizing or coatings, can enhance the functional properties of metals, including conductivity, wear resistance, and hardness.

Versatility of Materials:

Benefit: Metal finishing allows for the use of more cost-effective base metals by enhancing their properties, making them suitable for a broader range of applications.

Increased Durability:

Benefit: Finishing processes contribute to the durability of metal components, making them better equipped to withstand wear, tear, and environmental conditions.

Customization and Aesthetic Options:

Benefit: Metal finishing techniques offer a wide range of options for customization, allowing manufacturers to achieve specific textures, colors, and surface appearances.

Improved Cleanliness and Hygiene:

Benefit: In industries like healthcare, metal finishing, such as electropolishing, ensures smoother surfaces, reducing the risk of bacterial growth and improving cleanliness.

Cost-Effective Solutions:

Benefit: Certain finishing methods, like powder coating or electroplating, can be cost-effective, especially when compared to using more expensive base metals.

Drawbacks of Metal Finishing Techniques:

Increased Cost:

Drawback: Metal finishing processes add to the overall production cost of metal components, impacting the final price of the product.

Handling Sensitivity:

Drawback: Some finishing techniques, particularly those involving delicate coatings, require careful handling post-processing to avoid damage.

Extended Lead Time:

Drawback: Metal finishing can increase the lead time of the manufacturing process, impacting production schedules and delivery timelines.

Environmental Impact:

Drawback: Certain metal finishing processes involve the use of chemicals and may contribute to environmental concerns if not managed properly.

Limitations on Operating Range:

Drawback: Certain finishes, such as paint, may have temperature limitations, restricting the operating range of the finished product.

Complexity in Process Planning:

Drawback: Selecting the appropriate finishing technique requires careful consideration of various factors, adding complexity to the manufacturing process planning.

Maintenance Requirements:

Drawback: Some finishes may require specific maintenance to preserve their appearance and functionality over time.

Limited Application to Certain Materials:

Drawback: Certain finishing techniques are more suitable for specific materials, limiting their applicability across a wide range of metals.

Selecting the best finish for metal depends on various factors, and different scenarios call for specific techniques.

Here are recommendations based on specific criteria:

What is the best finish for metal?

There are many types of metal finishes, each with their own best-case scenario. The best procedure or method to follow during processing comes down to the end product’s specifications, the material used as well as your budget.

Best Finish for Corrosion Resistance:

Recommendation: For optimal corrosion resistance, particularly in environments prone to rusting, galvanizing is considered highly effective. However, it's essential to note that material selection also plays a significant role; opting for stainless steel over carbon steel can further enhance corrosion resistance.

Recommendation: When aesthetics are a top priority, polishing is often associated with high quality. The labor-intensive nature of polishing contributes to a sleek and visually appealing surface. Additionally, a high-quality sanded and painted finish, commonly used in automotive applications, can result in a visually stunning product.

Cheapest Metal Finishing Technique:

Recommendation: If budget constraints are the primary consideration, wet painting or powder coating are cost-effective options. These processes are highly automated, reducing labor costs, and they generally involve lower raw material expenses compared to some other finishing methods. This makes them practical choices for achieving a finished look without breaking the bank.

Conclusion:

Effective surface finishing is not only advantageous for end-users but also benefits manufacturers when executed with precision. GD HUB Precision Technology Co., Limited emerges as a powerhouse in the precision manufacturing world, providing small, medium, and large enterprises with a wide range of solutions, including CNC machining, extrusion molding, injection molding, rapid prototyping, and surface finishing services for metals and plastics.