CNC machining (Computer Numerical Control machining) is a manufacturing process that involves the use of computer-controlled machines to produce complex and precise parts and components from various materials such as metal, plastic, wood, and composites. The CNC machines are programmed with specific instructions to cut, drill, mill, or shape the material to create a finished product. The CNC machines use specialized software to translate a 3D CAD model into machine code that directs the tool path and coordinates the movement of the machine to achieve the desired shape and dimensions. CNC machining is widely used in various industries, including aerospace, automotive, medical, and electronics, due to its high accuracy, consistency, and efficiency.

What is CNC machining Used For?

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed computer software to control the movement of machine tools and equipment. It is widely used in various industries and applications, including:

Aerospace: CNC machining is used to manufacture complex aerospace components, such as engine parts, landing gear, and structural components.

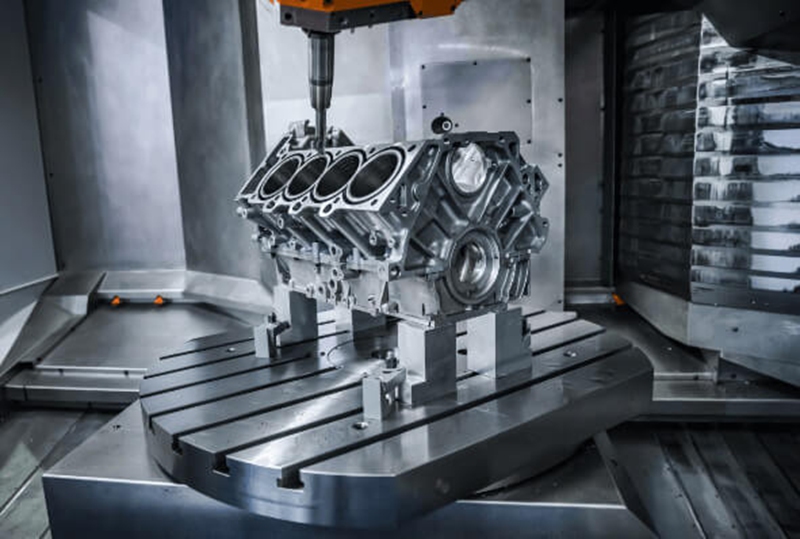

Automotive: CNC machining is used to produce high-precision engine components, transmissions, and other automotive parts.

Medical: CNC machining is used to manufacture medical implants, surgical instruments, and other medical devices that require high precision and accuracy.

Electronics: CNC machining is used to manufacture precision electronic components, such as printed circuit boards (PCBs), connectors, and housings.

Defense: CNC machining is used to manufacture complex military equipment and weapons, such as missiles, drones, and surveillance systems.

Jewelry: CNC machining is used to produce high-quality, intricate designs in jewelry, such as rings, bracelets, and pendants.

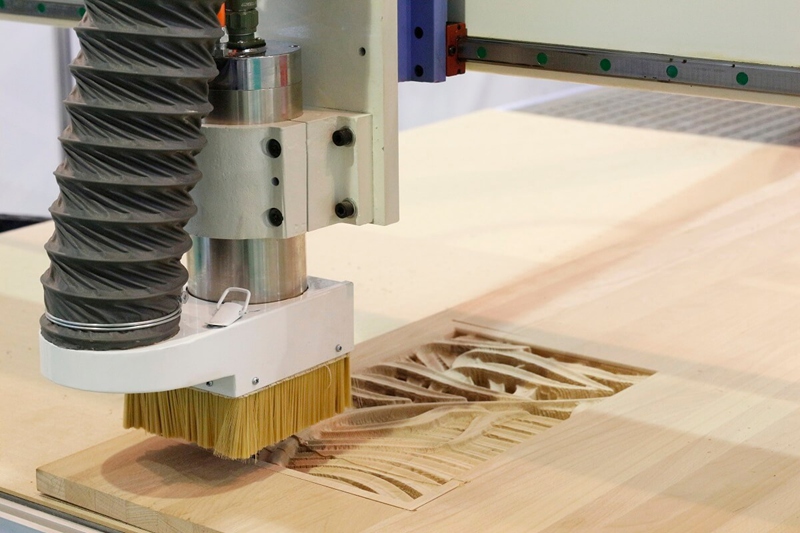

Woodworking: CNC machining is used to carve and cut wood into intricate designs for furniture, decorative items, and other wood products.

There are several kinds of CNC machining machines

There are several types of CNC machines, each designed to perform specific tasks and operations. Some common types of CNC machines include:

CNC Milling Machine: This machine uses rotary cutters to remove material from a workpiece. It can perform operations such as drilling, tapping, and milling to create complex shapes and features.

CNC Lathe Machine: This machine rotates a workpiece while a cutting tool removes material to create cylindrical parts. It can also perform operations such as drilling, boring, and threading.

CNC Router: This machine uses a rotating cutting tool to remove material from a workpiece, typically used for cutting and shaping wood, plastic, and other materials.

CNC Plasma Cutter: This machine uses a high-velocity stream of ionized gas to cut through metal sheets and plates.

CNC Laser Cutter: This machine uses a high-powered laser beam to cut through a variety of materials, such as metal, wood, plastic, and glass.

CNC EDM (Electrical Discharge Machining): This machine uses electrical discharges to remove material from a workpiece. It is commonly used for machining complex shapes and hard materials, such as titanium and tungsten.

Several types of CNC machining capabilities

CNC (Computer Numerical Control) machining several types of CNC machining capabilities, including:

Turning: This CNC machining process involves rotating a workpiece while a cutting tool is applied to remove material from the workpiece. Turning is used to create cylindrical parts, such as shafts, and is commonly used in the production of parts for the aerospace, automotive, and medical industries.

Milling: Milling is a CNC machining process that uses rotating cutting tools to remove material from a workpiece. Milling can be used to create a variety of shapes and features, including slots, holes, and pockets.

Drilling: CNC drilling is a process that uses a rotating cutting tool to create holes in a workpiece. Drilling is commonly used in the production of parts for the aerospace, automotive, and construction industries.

Grinding: CNC grinding is a process that uses abrasive wheels to remove material from a workpiece. Grinding is commonly used to create high-precision parts, such as those used in the aerospace and medical industries.

Laser cutting: CNC laser cutting uses a high-powered laser to cut and shape materials. Laser cutting is commonly used to create parts for the automotive, aerospace, and electronics industries.

Waterjet cutting: CNC waterjet cutting uses a high-pressure stream of water to cut and shape materials. Waterjet cutting is commonly used in the production of parts for the aerospace, automotive, and construction industries.

The difference between 3-axis CNC machining,4-axis CNC machining, 5-axis CNC machining.

3-axis, 4-axis, and 5-axis CNC machining refer to the number of axes of motion that a machine can move during the machining process.

3-axis CNC machining: This type of CNC machining is capable of moving the cutting tool along the X, Y, and Z axes. This allows for milling and drilling operations on three sides of a workpiece. It is commonly used for simple parts that require only straight cuts and flat surfaces.

4-axis CNC machining: In addition to the X, Y, and Z axes, 4-axis CNC machining also includes a rotary axis that rotates the workpiece. This allows for more complex parts to be machined, such as parts with curved surfaces or undercuts.

5-axis CNC machining: This type of CNC machining adds two rotary axes to the X, Y, and Z axes of a 3-axis machine. These additional axes allow for even more complex parts to be machined, including parts with compound angles, intricate contours, and deep cavities. 5-axis CNC machining is often used in the aerospace and automotive industries.

As the number of axes increases, the machine becomes more capable of producing complex shapes and features with greater precision and efficiency. However, the cost of the machine and the programming complexity also increase with the number of axes.

Must Know About ---GD-HUB'S CNC Machining Capabilities

GD-HUB's CNC machining center contains more than 80 CNC machines with a total of more than 100 experienced CNC machine operators and designers.

1. GD-HUB's CNC machining provides unparalleled precision, accuracy and repeatability, ensuring consistent output quality. This can help your project reduce defects, increase efficiency and guarantee part quality during machining.

2. GD-HUB's CNC machining can complete complex machining tasks in less time than other rrapid prtotype manufacturers, resulting in faster turnaround times and increased productivity.

3. GD-HUB experienced operators can program multiple operations on a part without the need for multiple machines and operators, which can save time, space and labor costs.

4. GD-HUB's number of CNC operators and programmers can be easily reprogrammed for new designs or modifications, making GD-HUB easily adaptable to changing customer needs.

5. GD-HUB's CNC machining can be highly automated, reducing the need for manual intervention and improving shop floor safety.

All of these advantages can help GD-HUB reduce costs, increase output, and improve customer satisfaction, making GD-HUB's CNC machining an attractive option to meet your manufacturing needs.