Introduction

In the realm of precision manufacturing, the final verdict on quality rests not with the complexity of the process but with the accuracy of the end product. GD-HUB, a leader in precision manufacturing services, understands this tenet deeply. Our suite of services, from CNC machining to 3D printing, is underpinned by an unwavering commitment to excellence. This commitment comes to fruition through our Coordinate Measuring Machine (CMM) inspection services. In this article, we will delve into what CMM is, its pivotal role in manufacturing, and how GD-HUB ensures that every fabricated component meets the zenith of precision.

What is CMM?

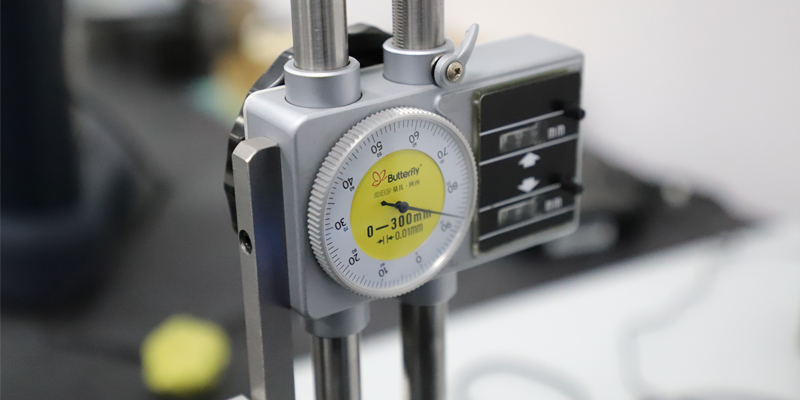

CMM stands for Coordinate Measuring Machine, a device used in the manufacturing process to measure the geometry of physical objects by sensing discrete points on the surface of objects with a probe. Various types of probes are used in CMMs, including mechanical, optical, laser, and white light. Each point is measured in three dimensions, which allows for a comprehensive evaluation of the product against the intended design.

How does CMM Function?

The CMM functions by interfacing with a computer system that has been fed with the precise design specifications of the product. As the probe touches different points on the item, the CMM records these locations and creates a 'map' of the product's dimensions. This map is then compared against the design blueprint to ensure that every angle, curve, and contour is as it should be, down to the minutest detail.

GD-HUB's CMM Inspection Service

Our CMM inspection service is the final checkpoint in the manufacturing process. Here’s what it encompasses:

Detailed Measurement: We obtain precise measurements of prototypes and parts, whether they are produced via extrusion molding, die casting, or any of our other manufacturing services.

Verification of Specifications: We verify that each component matches the exact specifications laid out in the design plans.

Quality Assurance: The CMM inspection helps us guarantee that the products are of the highest quality and are ready for use in their intended applications.

Reporting: After the inspection, we provide a detailed report that includes data and visual mappings of the measurements.

Why GD-HUB Use CMM Inspection?

Choosing GD-HUB's CMM inspection services means opting for unwavering accuracy. Our state-of-the-art CMM technology, combined with our skilled technicians, ensures that your components are not just made, but perfected. Our inspection process is your assurance that every product you receive is ready to perform, exactly as you intended.

Conclusion

In precision manufacturing, the difference between the nearly right and the exactly right lies in the accuracy of measurement. GD-HUB's CMM inspection services are not just a procedure; they are the seal of precision that marks every product that leaves our facility. Trust in GD-HUB to deliver components that meet the highest standards of precision, every time.

Experience unprecedented precision:

Are you ready to experience precision like never before? Contact GD-HUB today to learn more about how our CMM inspection services can elevate the quality and precision of your manufacturing projects.