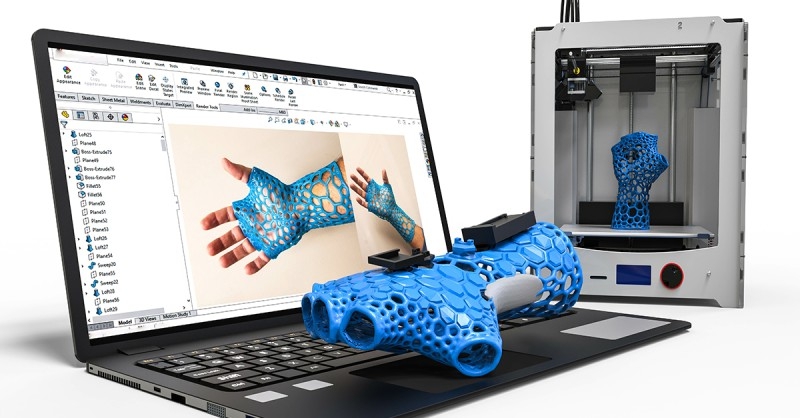

3D printing, also known as additive manufacturing, is a process of creating physical objects from digital designs using a layer-by-layer approach. The process starts with a 3D model created using a computer-aided design (CAD) software or obtained from a 3D scanner. The 3D printer then reads the design and produces the object by adding material layer by layer until the final object is complete.

The material used in 3D printing can vary depending on the printer and the application. Some common materials used include plastics, metals, ceramics, and even food.

3D printing technology has many potential applications in various fields, including prototyping, product design, architecture, automotive, aerospace, healthcare, and education. It has revolutionized the manufacturing industry by making it easier, faster, and more cost-effective to create prototypes and customized products.

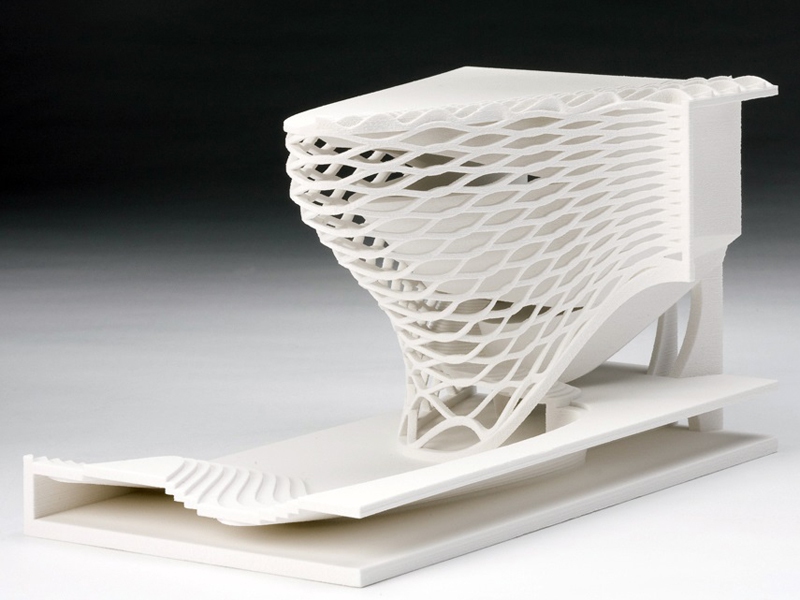

Customization: 3D printing allows for the creation of highly customized objects with unique shapes, sizes, and features. This can be especially useful in fields such as medicine and engineering, where customized products are often needed to fit specific patient or project requirements.

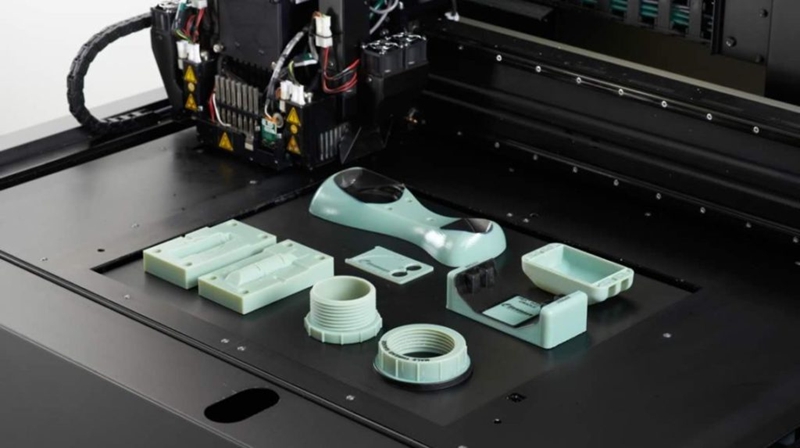

Rapid prototyping: 3D printing allows for the rapid creation of prototypes, which can save time and money compared to traditional prototyping methods. This can be especially useful for small businesses or startups that need to test new ideas quickly and efficiently.

Cost savings: 3D printing can be more cost-effective than traditional manufacturing methods, especially for low-volume production runs. This is because 3D printing allows for the production of complex shapes and designs in a single step, which can eliminate the need for multiple production steps.

Accessibility: 3D printing technology is becoming increasingly accessible, with more affordable printers and materials becoming available. This has opened up new opportunities for individuals and small businesses to create their own products and prototypes without the need for large investments in manufacturing equipment.

3D printing (additive manufacturing) is a rapidly growing technology that is widely used in these industries:

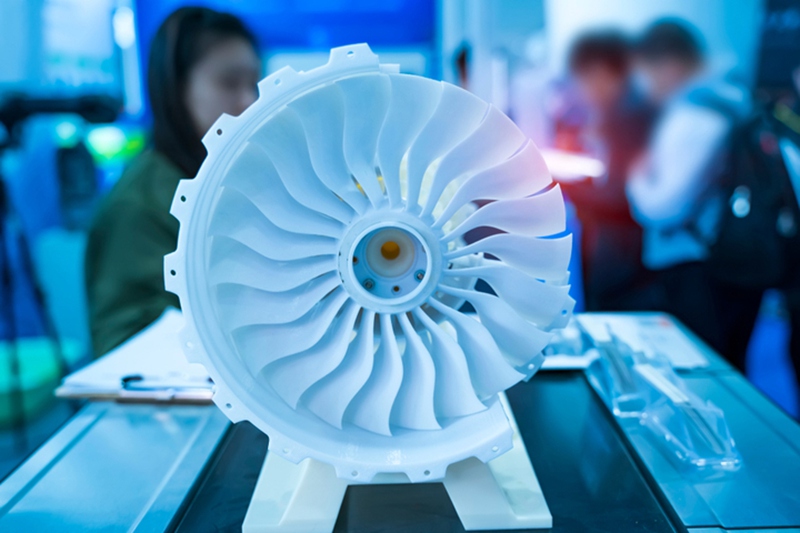

Manufacturing: 3D printing has revolutionized the manufacturing industry by enabling the creation of complex shapes and designs with minimal waste. It is used to produce prototypes, tooling, and end-use parts.

Healthcare: 3D printing is used in the medical field to create custom prosthetics, implants, and surgical tools. It can also be used to create replicas of organs for surgical training and planning.

Education: 3D printing is used in education to teach engineering, design, and architecture. It allows students to create physical objects from their designs and ideas.

Aerospace: 3D printing is used in the aerospace industry to create lightweight components for aircraft and spacecraft. It is also used to create prototypes and mockups for testing.

Fashion: 3D printing is used in the fashion industry to create unique and custom designs. It allows designers to create complex shapes and patterns that would be difficult to achieve with traditional manufacturing methods.

Art: 3D printing is used in the art world to create sculptures, installations, and other works of art. It allows artists to create complex and intricate designs that would be difficult to achieve with traditional methods.

Food: 3D printing is used in the culinary world to create intricate and unique food designs. It allows chefs to create custom shapes and textures that would be difficult to achieve with traditional cooking methods.

Architecture: 3D printing is used in architecture to create models of buildings and structures. It allows architects to create physical representations of their designs for testing and feedback.

There are several different processes available for 3D printing, including:

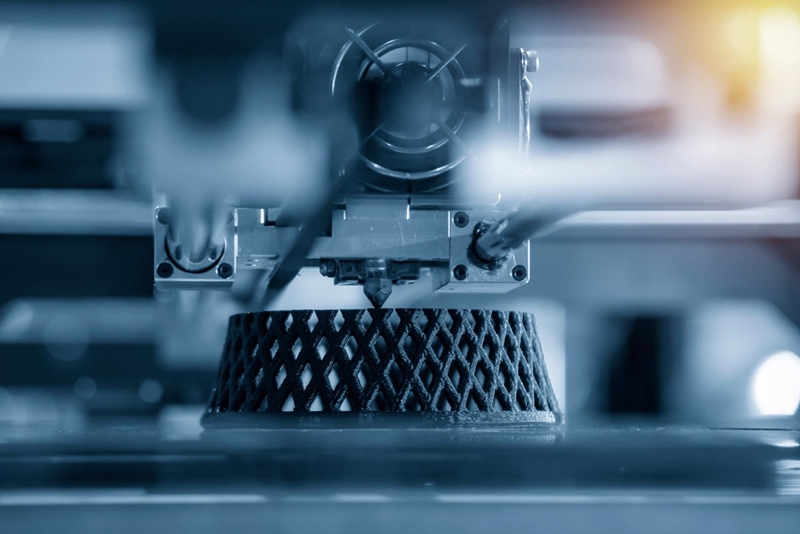

Fused Deposition Modeling (FDM): FDM is the most common 3D printing process, in which a thermoplastic material is melted and extruded through a nozzle, layer by layer, to create the final object.

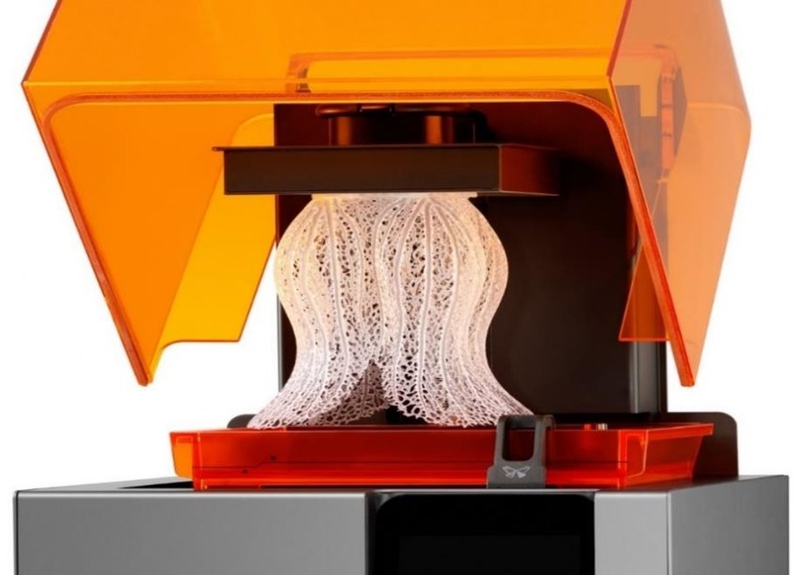

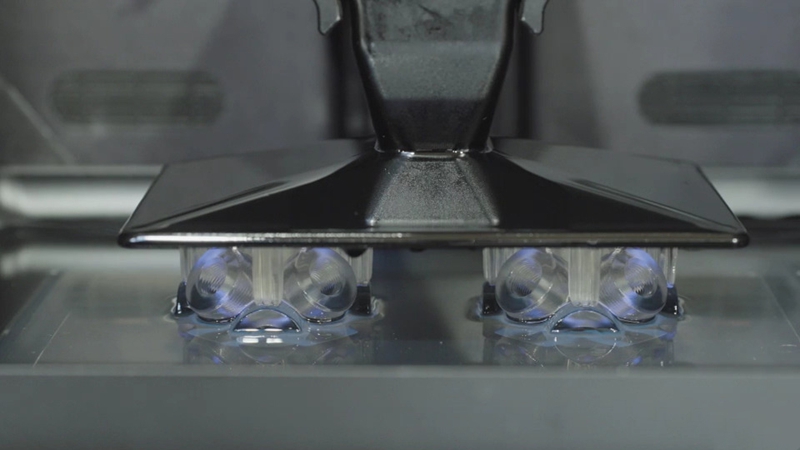

Stereolithography (SLA): SLA is a process that uses a liquid resin that is cured with a UV laser to create the final object.

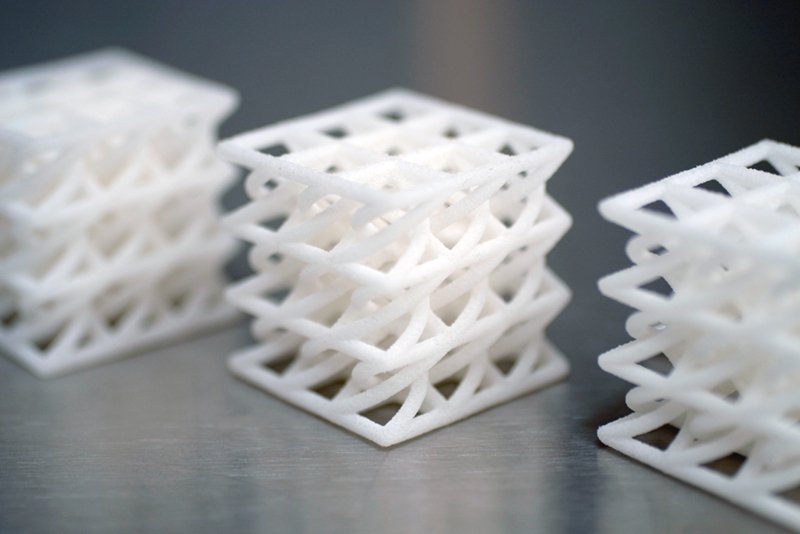

Selective Laser Sintering (SLS): SLS is a process that uses a laser to selectively sinter a powdered material, such as nylon or metal, layer by layer, to create the final object.

Digital Light Processing (DLP): DLP is a similar process to SLA, but instead of using a laser to cure the resin, it uses a light projector to create the final object.

Binder Jetting: Binder Jetting is a process in which a liquid binder is selectively deposited onto a powdered material, such as sandstone or metal, layer by layer, to create the final object.

Material Jetting: Material Jetting is a process in which a liquid material, such as photopolymer, is jetted onto a build platform layer by layer and cured by a UV light to create the final object.

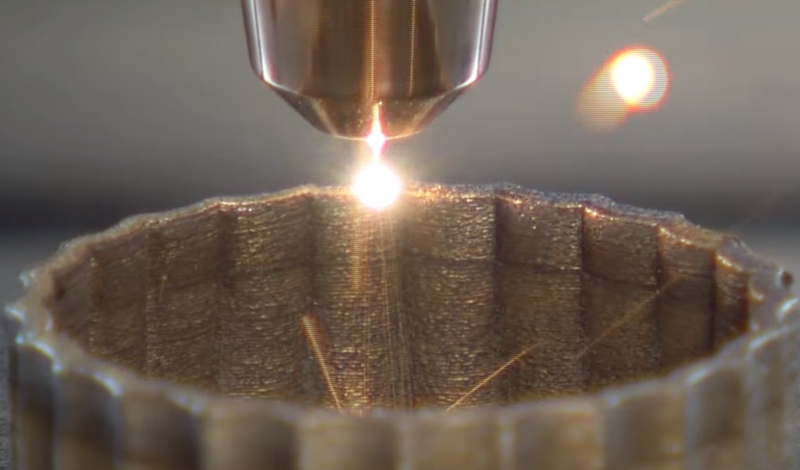

Directed Energy Deposition (DED): DED is a process that uses a nozzle to deposit melted material onto a substrate to create the final object. This process is commonly used for creating large parts or repairing existing parts.

The choice of which process to use will depend on your specific requirements of the project, including the desired material properties, resolution, and speed.

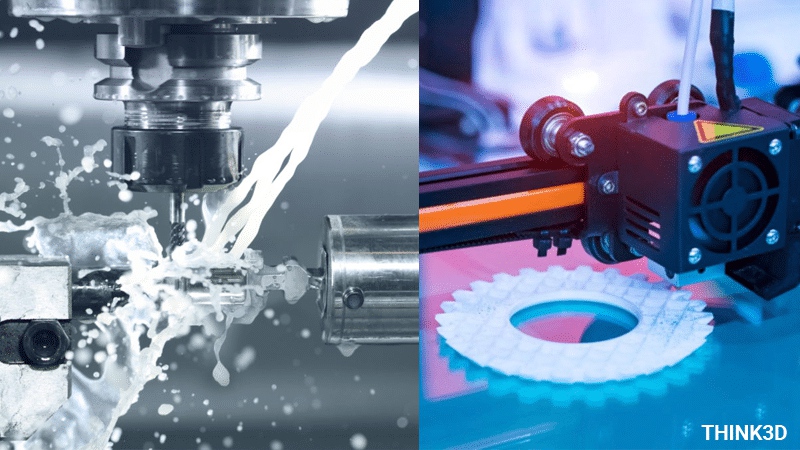

CNC machining and 3D printing are two popular manufacturing techniques used in modern industries. While both techniques can produce high-quality parts, there are several differences between them.

CNC machining involves using computer-controlled machines to remove material from a solid block of material to create a part. The machine follows a pre-programmed set of instructions to precisely cut and shape the material into the desired shape. CNC machining is typically used for creating parts from metals, plastics, and other materials that can be machined.

On the other hand, 3D printing, also known as additive manufacturing, involves building a part layer by layer using a 3D printer. The printer deposits material, such as plastic or metal, onto a build platform in a pre-determined pattern until the part is complete. 3D printing can produce complex geometries and shapes that would be difficult or impossible to make with traditional machining techniques.

The choice between CNC machining and 3D printing depends on several factors, such as the material, the complexity of the part, the required accuracy, and the desired quantity. CNC machining is generally faster and more accurate than 3D printing, making it a good choice for producing high volumes of parts that require tight tolerances. 3D printing is better suited for producing complex shapes and low-volume production runs.

Both techniques have their advantages and disadvantages, and the choice between them will depend on the specific requirements of the project.

The cost of 3D-printed rapid prototypes can vary depending on several factors, such as the size and complexity of the design, the printing material, the printing technology used, and the location of the service provider.

To get a cost estimate for 3D-printed rapid prototypes, please contact GD-HUB and provide us with design specifications. We can then provide a quick quote based on your project requirements and design.