Introduction

Aluminum extrusion services are pivotal in the modern manufacturing landscape, offering versatile, efficient, and cost-effective solutions for producing aluminum profiles. This article delves into the process of aluminum extrusion, its benefits, applications, and why it stands as a cornerstone in various industries.

What is Aluminum Extrusion?

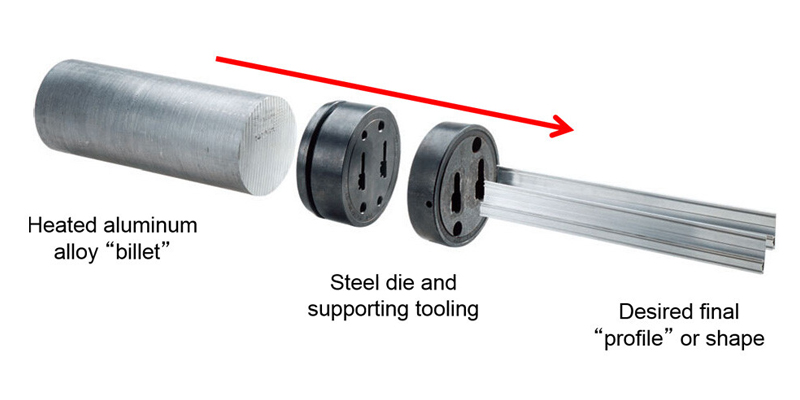

Aluminum extrusion is a process that transforms aluminum alloy into objects with a definitive cross-sectional profile for a wide range of uses. The aluminum is forced through a die of the desired shape and size, resulting in elongated aluminum parts with uniform cross-sections. This process is favored for its ability to create complex cross-sections and to work materials that are brittle, because the material only encounters compressive and shear stresses.

The Process of Aluminum Extrusion

The aluminum extrusion process involves several key steps:

Design and Creation of the Die: A die is designed and created to match the desired profile.

Heating the Aluminum Billet: Aluminum billets are heated to the desired temperature to make them malleable.

Extrusion: The heated billet is then pushed through the die.

Cooling and Hardening: The extruded aluminum is cooled and then subjected to heat treatment to harden.

Cutting and Finishing: The extruded parts are cut to length and can be finished with operations such as anodizing or painting.

Advantages of Aluminum Extrusion Services

Versatility in Design: Allows for the creation of complex shapes that are structurally sound and aesthetically pleasing.

Strength and Durability: Aluminum extrusions offer high strength-to-weight ratio, making them ideal for demanding applications.

Cost-Effectiveness: Efficient production process and minimal material wastage.

Corrosion Resistance: Aluminum naturally forms a protective oxide coating, which makes extruded profiles resistant to corrosion.

Thermal Conductivity: Excellent for applications requiring heat dissipation, like radiators and heat sinks.

Material | Properties | Typical Applications |

Aluminum | Lightweight, high strength-to-weight ratio | Construction (windows, doors), automotive parts, aerospace components |

Plastics (e.g., PVC, HDPE, LDPE, PP) | Versatile, lightweight, corrosion-resistant | Packaging, plastic films, pipes, profiles, insulation |

Rubber | Flexible, durable, resistant to heat and chemicals | Seals, gaskets, hoses, automotive parts |

Copper | High electrical conductivity, malleable | Electrical wiring, plumbing, roofing |

Steel (including stainless steel) | Strong, durable, corrosion-resistant (stainless) | Structural components, automotive parts, appliances |

Titanium | High strength, corrosion-resistant, biocompatible | Aerospace, medical implants, automotive |

Magnesium | Very lightweight, good strength-to-weight ratio | Aerospace, automotive, electronics |

Polyethylene (PE) | Durable, flexible, chemical resistant | Pipes, containers, bottles, insulation |

Polystyrene (PS) | Lightweight, easy to mold, insulating | Packaging, disposable cutlery, insulation |

Polypropylene (PP) | High chemical resistance, tough, flexible | Automotive parts, textiles, consumer goods |

Thermoplastic Elastomers (TPE) | Flexible, recyclable, can be over-molded | Automotive parts, medical devices, consumer products |

Applications of GD-HUB'S Aluminum Extrusion Services

Aluminum extrusion is used across various sectors:

Construction: For frames, railings, and structural components.

Automotive: In manufacturing components for vehicles, including body parts and frames.

Aerospace: For lightweight, strong components in aircraft construction.

Electronics: In heat sinks and frames for electronic devices.

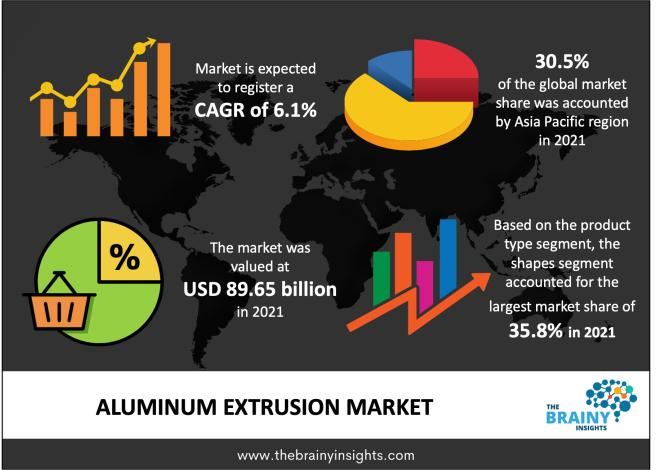

The Future of Aluminum Extrusion in Manufacturing

The future of aluminum extrusion services looks bright, with ongoing advancements in extrusion technology and aluminum alloys. These innovations will enable the production of more complex, lightweight, and strong components, further expanding the possibilities in design and manufacturing needs.

Year | Market Value (Billions USD) |

2013 | 6.00 |

2014 | 6.30 |

2015 | 6.60 |

2016 | 6.90 |

2017 | 7.20 |

2018 | 7.60 |

2019 | 8.00 |

2020 | 8.40 |

2021 | 8.90 |

2022 | 9.54 |

2023 | 10.26 |

Rising Economy of Extruded Markets from 2013 to 2023.

Conclusion

Aluminum extrusion services play a critical role in modern manufacturing, offering a unique combination of design flexibility, strength, and cost efficiency. As industries continue to seek innovative solutions in materials and manufacturing processes, aluminum extrusion services are set to remain a key player in the global manufacturing arena.

If you're seeking comprehensive extrusion services, GD-HUB is your go-to source. They offer a wide range of extrusion solutions tailored to meet various industrial needs.

Whether you require extrusion for metals like aluminum, copper, or steel, or for various plastics and rubber, GD-HUB has the expertise and equipment to deliver high-quality results.