Introduction to 5-Axis CNC Machining

5-Axis CNC (Computer Numerical Control) machining stands as a pinnacle of technological advancement in the manufacturing industry. This method employs cutting-edge technology allowing for the movement of tools and parts across five different axes simultaneously. This capability significantly surpasses the limitations of the traditional 3-axis approach, enabling more complex and precise machining.

Benefits of 5-Axis CNC Machining

Versatility Across Industries: One of the primary advantages of 5-axis CNC machining is its versatility. It's invaluable in a variety of sectors, including aerospace, automotive, medical, and energy. This versatility stems from its ability to produce complex parts with high precision, which are often required in these high-tech industries.

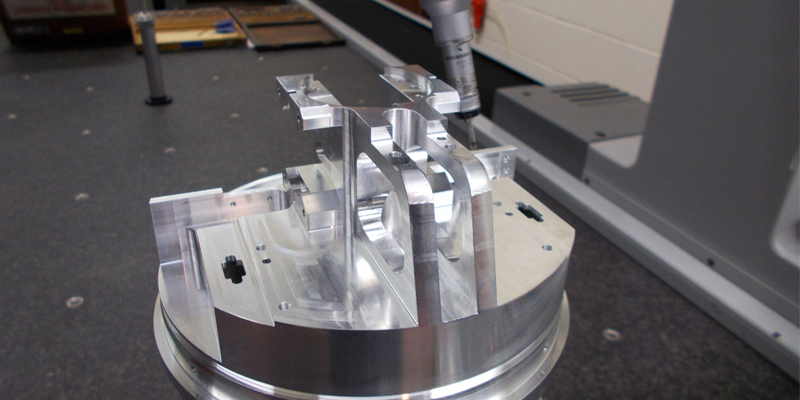

Precision in Design Validation: The precision of 5-axis CNC machining is unmatched. It allows for the production of parts with intricate geometries and tight tolerances, which is crucial for industries where precision is paramount. This precision also plays a significant role in design validation, ensuring that parts meet the exact specifications and function as intended.

Streamlining Design Validation Process: By utilizing 5-axis technology, manufacturers can significantly streamline their design validation process. This technology allows for the creation of more accurate prototypes faster, enabling quicker feedback and iteration. As a result, the overall time from design to production is reduced, enhancing efficiency and reducing costs.

Boosting Prototyping Efficiency: 5-axis CNC machining accelerates the prototyping process, allowing for the rapid production of complex parts. This efficiency is crucial in today’s fast-paced market, where getting a product from concept to market quickly can be a significant competitive advantage.

Real-World Applications Across Industries

From aerospace to medical devices, 5-axis CNC machines are making a significant impact. Their precision and versatility are invaluable in producing high-quality, complex components efficiently.

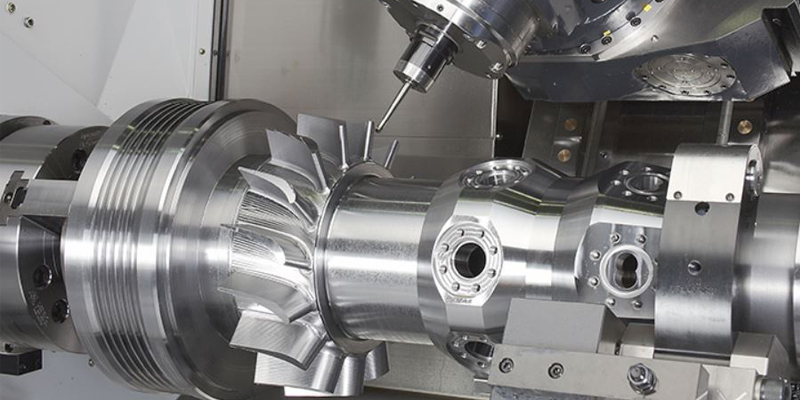

1. Aerospace Industry: In the aerospace industry, where precision and reliability are paramount, 5-axis CNC machines play a crucial role. These machines are used to manufacture critical components, such as turbine blades and engine casings, with exceptional accuracy and consistency. By leveraging the capabilities of 5-axis machines, aerospace manufacturers can ensure the performance and safety of their aircraft.

2. Automotive Industry: In the automotive industry, 5-axis CNC machines are used for the production of complex parts, including engine blocks, cylinder heads, and transmission components. The ability to create intricate shapes and contours allows for the optimization of component design, leading to improved performance and fuel efficiency. Moreover, the speed and precision of 5-axis machines enable automotive manufacturers to meet tight production schedules and deliver high-quality vehicles to market.

3. Medical Device Manufacturing: The medical device industry relies heavily on 5-axis CNC machines to produce intricate and precise components. From surgical instruments to prosthetics and implants, these machines enable manufacturers to create complex geometries that meet the stringent requirements of the medical field. The accuracy and reliability of 5-axis machines are crucial in ensuring the safety and effectiveness of medical devices.

4. Tool and Die Industry: In the tool and die industry, where precision is of utmost importance, 5-axis CNC machines are indispensable. These machines are used to manufacture complex molds and dies with exceptional accuracy, allowing for the production of high-quality parts. The versatility of 5-axis machines also enables the creation of intricate details and complex contours, ensuring the optimal performance of the molds and dies.

5. Architecture and Design: 5-axis CNC machines are also finding applications in the architecture and design fields. These machines allow for the creation of complex and sculptural forms, enabling architects and designers to push the boundaries of creativity. From custom furniture to architectural elements, 5-axis machines offer the precision and versatility required to bring innovative designs to life.

These case studies highlight the diverse applications of 5-axis CNC machines across various industries. The ability of these machines to deliver precision, speed, and versatility makes them invaluable in modern manufacturing.

Top 5 Brands in 5-Axis CNC Machines

The top brands in 5-Axis CNC machines, as of 2023, include:

Haas: Based in the USA, Haas Automation is the largest CNC machine tool builder in the western world. Known for rugged machines at reasonable prices, Haas offers a line of CNC mills, lathes, rotary tables, and more. Their machines are designed for continuous operation in demanding production environments and are popular for small to mid-sized shops as well as large-scale operations.

Yamazaki Mazak: This Japanese company, commonly known as Mazak, manufactures a variety of CNC mills, lathes, machining centers, and multi-tasking machines. They are recognized for their smooth and accurate machining capabilities, rapid traverse speeds, high spindle speeds, and versatile 5-axis machines. Mazak is well-suited for medium to high-volume production environments.

Okuma: Another leading Japanese CNC machine manufacturer, Okuma, offers a wide variety of CNC lathes, mills, machining centers, grinders, and other specialty machines. Their machines are known for precision, with thermostable constructions and intelligent technology functions. Okuma machines are suitable for both production jobs and custom one-offs.

DMG Mori: An international company formed from a merger of German and Japanese manufacturers, DMG Mori is known for its extensive and innovative product lines. Their machines, which include 5-axis and multi-tasking capabilities, are renowned for extreme rigidity, accuracy, and excellent surface finishes. They cater to industries requiring machining of complex, tight-tolerance components.

Doosan: Hailing from South Korea, Doosan Machine Tools offers a line of technologically advanced mills, lathes, and machining centers. Known for value pricing and high-performance, Doosan machines are a good choice for increasing production and improving part accuracy, particularly in small to mid-sized shops. Their machines include large capacity machining centers and compact mills with high torque

Conclusion

5-Axis CNC machining is a game-changer in the manufacturing industry, offering unparalleled precision, efficiency, and versatility. Its impact is evident across various sectors, and its role in enhancing design validation and prototyping efficiency cannot be overstated. As technology continues to evolve, the importance of 5-axis CNC machining in maintaining a competitive edge in the manufacturing industry will only increase.

GD-HUB: Revolutionizing Manufacturing with State-of-the-Art 5-Axis CNC Machining

Discover Precision Engineering with GD-HUB

Are you looking for unparalleled precision and innovation in manufacturing? Look no further than GD-HUB, a leader in 5-axis CNC machining services. Our state-of-the-art machines enable the creation of complex shapes and geometries with extraordinary accuracy and speed. Whether you're involved in aerospace, automotive, medical, or any high-precision industry, GD-HUB's advanced technology and engineering processes are tailored to meet your exact needs.

Your Partner in Innovation

GD-HUB is not just a service provider; we are your partners in innovation. Our commitment to precision, efficiency, and flexibility makes us the ideal choice for your prototyping and manufacturing needs. Whether you're looking to bring a complex design to life or seeking a partner for high-precision manufacturing, GD-HUB is here to turn your ideas into reality.

Superior Precision and Complexity: GD-HUB’s 5-axis CNC machines can perform multiple machining operations in a single setup, ensuring greater accuracy and consistency in the finished product.

Increased Efficiency and Lower Costs: With experienced CNC operators and fewer required setups and tool changes, we offer faster production times and lower costs.

Design Flexibility: Our machines provide greater design flexibility, capable of producing more complex parts that are difficult or impossible to manufacture with traditional techniques.

Material Diversity: GD-HUB works with a diverse range of materials, including metals like steel, aluminum, brass, and titanium, as well as plastics, ceramics, and more, offering over 100 production-grade materials to meet your project needs.

Take the Next Step

Ready to experience the difference that GD-HUB can make in your manufacturing process? Contact us today to discuss your unique requirements and discover how our 5-axis CNC machining services can benefit your project. Let's shape the future of manufacturing together with GD-HUB's cutting-edge technology and expert team.

Contact GD-HUB Now – Your innovation awaits!