In the realm of surface finishing processes, an array of sophisticated techniques stands as pillars in elevating material quality. Let's delve into the intricacies of the 14 common surface finishing processes, unraveling the unique differences and working principles that distinguish each method, along with their diverse applications.

1) Polishing:

Working Principle: Employing abrasives like sandpaper and buffing wheels, polishing meticulously eradicates imperfections, scratches, and surface irregularities, resulting in a reflective surface.

Applications: Primarily used for enhancing the visual appeal of metals, plastics, and wood surfaces.

2) Grinding:

Working Principle: Utilizing abrasive wheels or belts, grinding tactically removes material to achieve precise surfaces or dimensional accuracy.

Applications: Widely adopted for refining metal shapes and achieving stringent tolerances.

3) Buffing:

Working Principle: Employing rotating wheels or brushes with abrasive compounds, buffing imparts a smooth and lustrous finish.

Applications: Ideal for enhancing shine and reflectivity across metals, plastics, and select wood surfaces.

4) Sanding:

Working Principle: Using abrasive materials like sandpaper, sanding tackles imperfections, smoothens surfaces, and prepares them for subsequent finishing.

Applications: Fundamental in surface preparation across various materials.

5) Honing:

Working Principle: Precision is the essence as abrasive stones refine geometric form, surface texture, and overall finish.

Applications: Applied for achieving superior surface quality and geometric precision.

6) Lapping:

Working Principle: Abrasive compounds and surface movement achieve high dimensional accuracy and finish, especially on flat or spherical surfaces.

Applications: Critical for precision in dimensional accuracy and surface finish.

7) Electroplating:

Working Principle: Electrochemical deposition forms a thin metal layer on a substrate, enhancing appearance, corrosion resistance, and functional properties.

Applications: Diverse, spanning from aesthetic enhancement to functional improvement.

8) Anodizing:

Working Principle: An electrochemical process primarily for aluminum, forming a protective oxide layer, enhancing corrosion resistance, and providing diverse finishes.

Applications: Predominantly used for aluminum with varied finishes from matte to glossy.

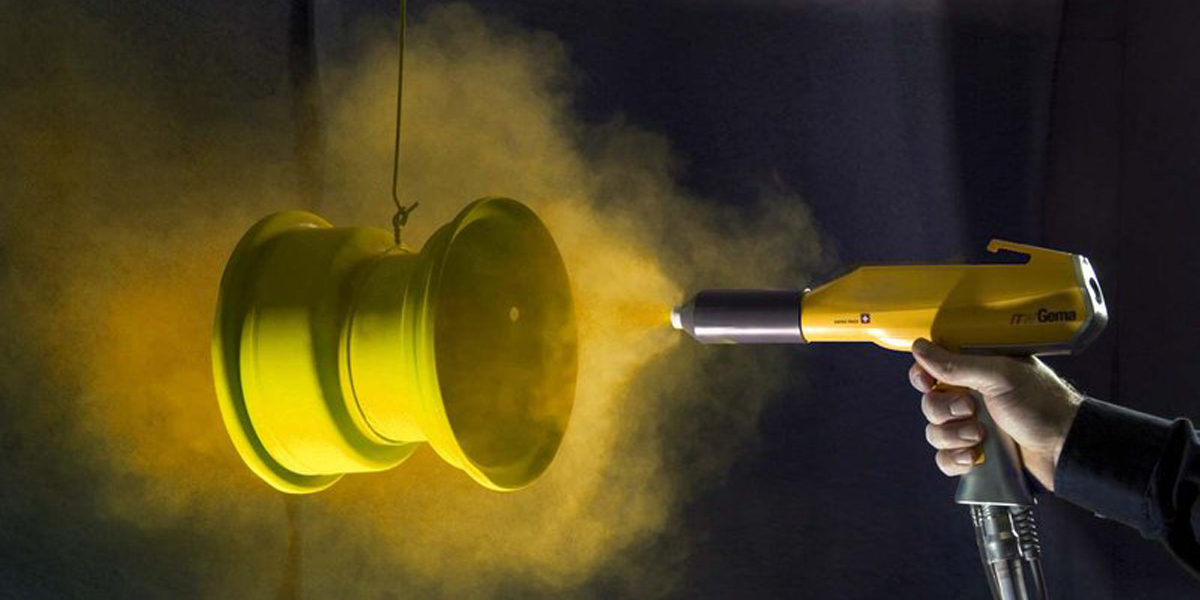

9) Powder Coating:

Working Principle: Electrostatically charged powder particles adhere to surfaces, cured under heat to yield a durable finish with excellent impact and chemical resistance.

Applications: Wide-ranging, offering durability and versatility in finish.

10) Galvanizing:

Working Principle: A chemical process, particularly for stainless steel, removing contaminants and forming a protective oxide layer to enhance corrosion resistance.

Applications: Crucial for stainless steel, minimizing rust and staining risks.

11) Passivation:

Working Principle: A chemical process on stainless steel to enhance corrosion resistance by removing contaminants.

Applications: Ensures heightened corrosion resistance in stainless steel applications.

12) Coating:

Working Principle: Application of protective layers for varied purposes like protection, appearance enhancement, or functional improvement.

Applications: Diverse, ranging from aesthetic to functional requirements.

13) Sandblasting:

Working Principle: Propelling abrasive particles against surfaces with compressed air, removing contaminants and creating textured or matte finishes.

Applications: Effective in cleaning and texturing surfaces.

14) Etching:

Working Principle: Chemical or acid-based removal of material to create patterns, textures, or designs on surfaces.

Applications: Widely employed on metals, glass, ceramics, and plastics for decorative or functional purposes.

Ⅱ. Apart from making the product more aesthetically pleasing, what functional role does the surface treatment have?

From improving corrosion resistance to enhancing aesthetics, surface finishing plays a vital role in the manufacturing industry.

Aesthetics: Surface treatment enhances the visual appeal of a product or material. It can provide a smooth, glossy, or textured appearance, and it can include the application of colors, patterns, or decorative elements. A well-finished surface can significantly improve the overall appearance and attractiveness of a product.

Protection: Surface treatment helps protect materials from various environmental factors, such as corrosion, wear, abrasion, chemicals, and UV radiation. Coatings like paints, anodizing, and galvanizing form protective barriers that shield the underlying material, extending its lifespan and reducing maintenance requirements.

Improved Cleanability: Certain surface finishes can make materials easier to clean by reducing surface roughness and minimizing the adhesion of contaminants, dirt, or stains. Smooth, non-porous finishes are often used in applications where cleanliness and hygiene are essential, such as in food processing, healthcare, or sanitary environments.

Functional Performance: Surface treatment processes can modify the functional properties of a material. For example, polishing or grinding can improve dimensional accuracy, reduce friction, or create specific surface textures to enhance grip or promote lubrication. Coatings can add properties like conductivity, insulation, or resistance to temperature extremes.

Durability and Wear Resistance: Surface finishing treatments, such as hardening processes like heat treatment or plating, can increase the hardness, wear resistance, and toughness of materials. This is particularly important in applications involving high-stress environments or abrasive conditions.

Improved Surface Integrity: Surface treatment can eliminate or reduce surface defects, imperfections, or roughness resulting from manufacturing processes. It can improve the surface integrity, reducing stress concentrations and the risk of failure or fatigue.

Branding and Identification: Surface treatment techniques, such as engraving, embossing, or printing, can be used for branding, product identification, or marking purposes. These techniques help in providing information, logos, serial numbers, or other identifying features on the surface of a product.

Ⅲ. Surface finishes available for common materials

Metals | Plastics | Ceramics | Glass | Wood | Composites | Leather | Stone |

Polishing | Polishing | Polishing | Polishing | Sanding | Sanding | Dyeing | Polishing |

Grinding | Painting | Glazing | Grinding | Staining | Painting | Waxing | Honing |

Buffing | Powder coating | Painting | Sandblasting | Painting | Gel coating | Polishing | Sandblasting |

Plating | Vacuum metallizing | Printing | Etching | Varnishing | Clear coating | Burnishing | Brushing |

Powder coating | Printing | Coating | Coating | Lacquering | Varnishing | Coating | Acid etching |

Anodizing | Sandblasting | Sandblasting | Waxing | Polishing | Coating | ||

Passivation | Etching | Etching | Oil finishing | Coating | |||

Sandblasting | Coating | Coating | |||||

Coating | |||||||

Etching |

In the precision manufacturing industry, where attention to detail and the pursuit of perfection are paramount, surface finishing emerges as a critical and indispensable facet:

Dimensional Accuracy and Tolerance:

Precision machining demands exacting dimensional accuracy and tight tolerances. Surface finishing processes such as grinding and honing play a pivotal role in achieving and maintaining these critical specifications. They ensure that components fit seamlessly and function precisely within intricate assemblies.

Enhanced Aesthetics:

In precision manufacturing, aesthetics are not merely cosmetic; they reflect craftsmanship and attention to detail. Surface finishing techniques like polishing and coating not only provide a visually appealing final product but also convey a sense of quality and excellence to clients and end-users.

Corrosion Resistance:

Precision components often operate in demanding environments, exposing them to corrosive elements. Surface finishing methods like anodizing, electroplating, and passivation form protective layers that shield against corrosion. This is paramount for ensuring the longevity and reliability of precision-engineered parts.

Improved Cleanability:

Precision machinery and equipment often require meticulous cleaning. Smooth, well-finished surfaces (achieved through processes like buffing and lapping) minimize the retention of contaminants and facilitate easier cleaning. This is particularly crucial in industries such as healthcare and food processing.

Functional Performance:

Surface finishing is not merely about appearances; it directly impacts the functional performance of components. Techniques like coating can impart specific properties such as conductivity, insulation, or resistance to extreme temperatures, tailoring materials to meet precise functional requirements.

Reduced Friction and Wear:

Precision components frequently experience dynamic interactions, necessitating low friction and wear. Surface finishing processes like polishing and coatings can significantly reduce friction, extending the lifespan of components and maintaining consistent performance over time.

Surface Integrity and Reliability:

Precision manufacturing demands flawless surface integrity to ensure the reliability of components. Surface treatment eliminates imperfections, roughness, and stress concentrations that may compromise structural integrity. This is crucial in applications where reliability is non-negotiable, such as aerospace or medical devices.

Customization and Branding:

In precision manufacturing, components often bear specific markings or branding. Techniques like engraving, embossing, or specialized coatings provide avenues for customization and branding, aiding in product identification and traceability.

Optical and Electronic Applications:

In industries like optics and electronics, surface finish is of utmost importance. Processes like etching enable the creation of intricate patterns and structures on surfaces, crucial for optical devices, microelectronics, and semiconductor manufacturing.

Surface finishing in precision manufacturing is not a mere afterthought but a fundamental aspect of the entire production process. It ensures that the meticulous engineering invested in creating precision components is complemented by a surface quality that aligns with the high standards of the industry. From functionality to aesthetics, surface finishing is the finishing touch that elevates precision manufacturing to an art form.